содержание .. 914 915 916 917 ..

Nissan Murano. Manual - part 916

BACK DOOR TRIM

INT-41

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

K

L

M

A

B

INT

N

O

P

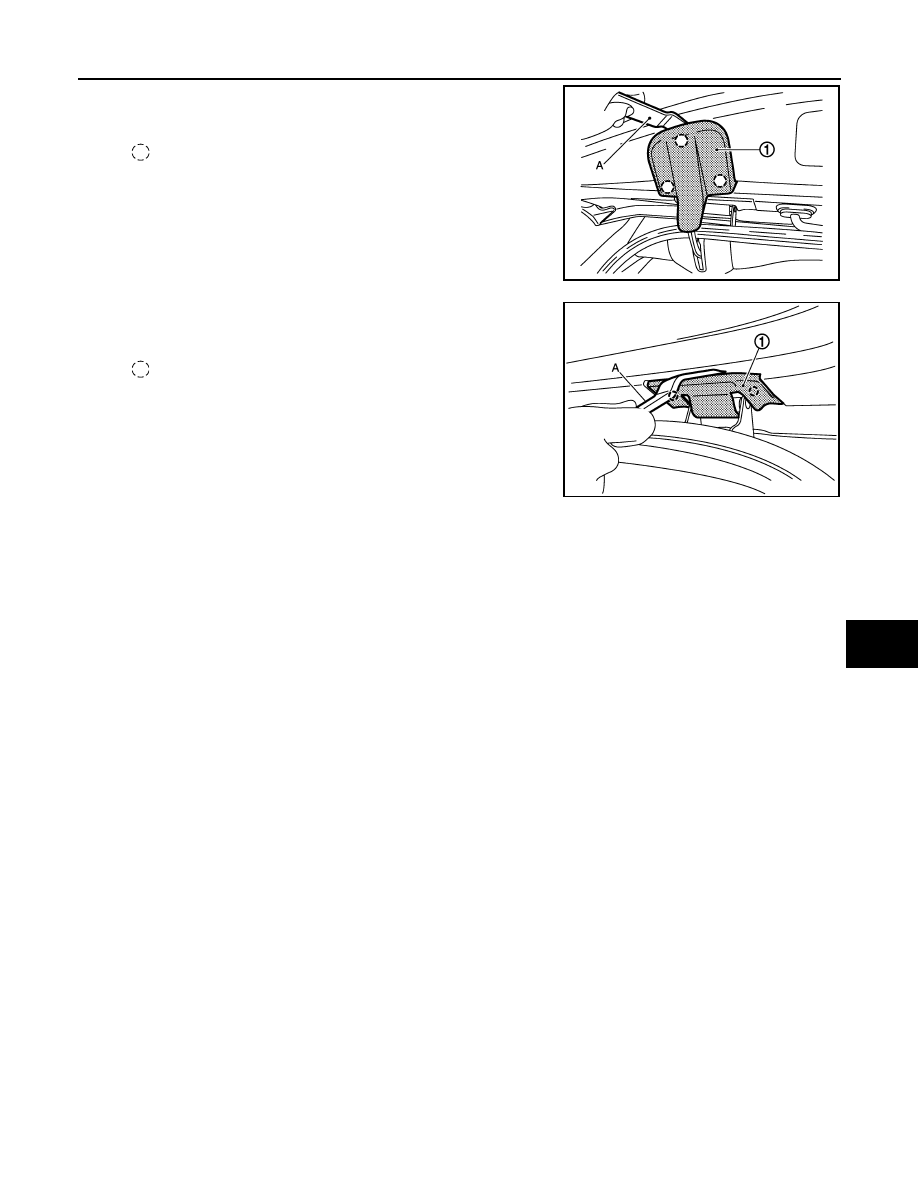

10. Disengage back door upper cover (1) fixing clips with remover

tool (A) and then remove back door upper cover (LH and RH).

11. Disengage back door hinge cover (1) fixing clips with remover

tool (A) and then remove back door hinge cover (LH and RH).

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

When installing back door trim, check that clips are securely fitted in panel holes on body, and then

press them in.

: Clip

JMJIA2567ZZ

: Clip

JMJIA1692ZZ