содержание .. 822 823 824 825 ..

Nissan Murano. Manual - part 824

HAC-70

< DTC/CIRCUIT DIAGNOSIS >

[WITHOUT 7 INCH DISPLAY]

BLOWER MOTOR

BLOWER MOTOR

Description

INFOID:0000000009722088

COMPONENT DESCRIPTION

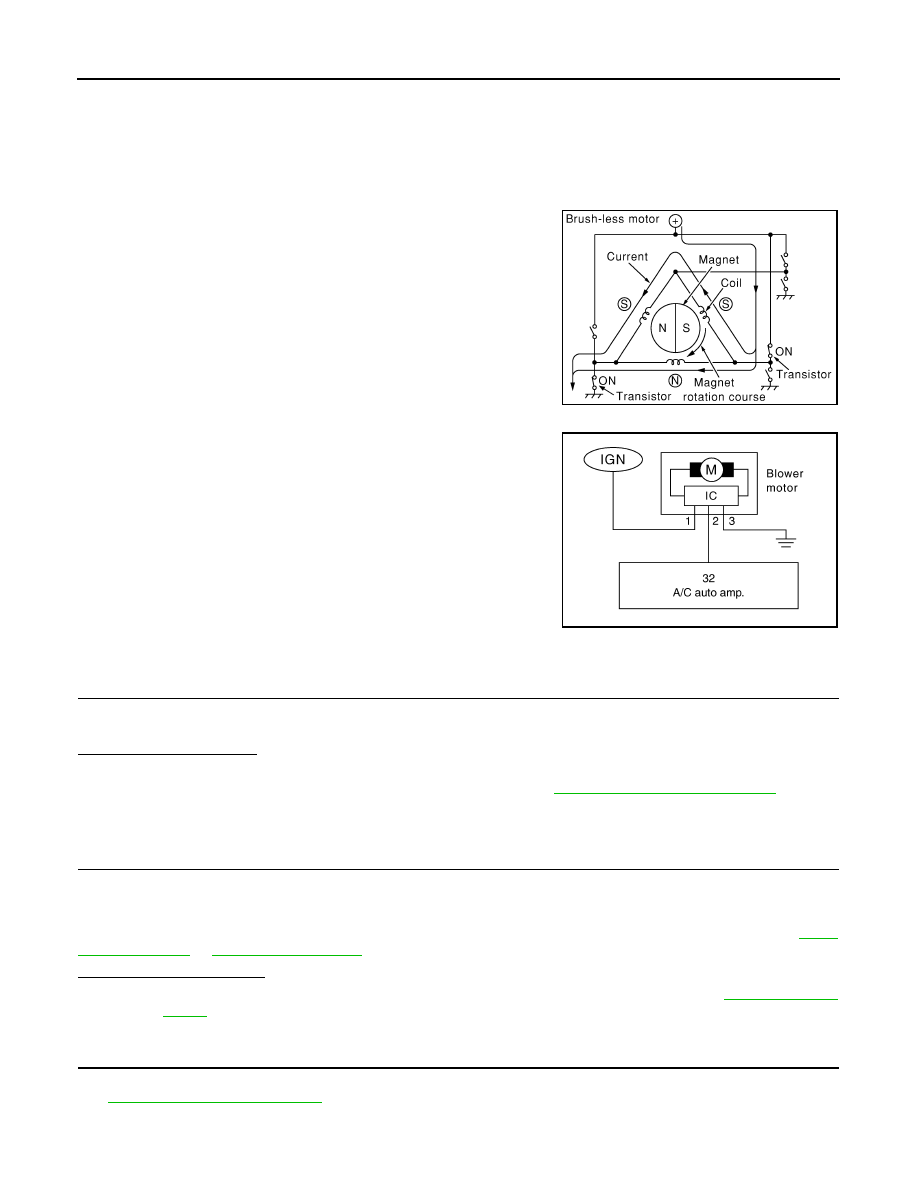

Brush-less Motor

The blower motor utilizes a brush-less motor with a rotating magnet.

Quietness is improved over previous motors where the brush was

the point of contact and the coil rotated.

Blower Motor Circuit

Component Function Check

INFOID:0000000009722089

1.

CHECK OPERATION

1.

Warm up the engine.

2.

Operate the fan control dial. Check that the fan speed and indicator are switched for all fan speeds.

Does it operate normally?

YES

>> INSPECTION END

NO

>> Perform trouble diagnosis for the blower motor. Refer to

Diagnosis Procedure

INFOID:0000000009722090

1.

CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT

1.

Using CONSULT, perform “SELF-DIAGNOSIS RESULTS” of HVAC.

2.

Check if any DTC No. is displayed in the self-diagnosis results.

NOTE:

If DTC is displayed along with DTC U1000 or U1010, first diagnose the DTC U1000 or U1010. Refer to

.

Is any DTC No. displayed?

YES

>> Perform the diagnosis that is applicable to the sensor and actuator. Refer to

.

NO

>> GO TO 2.

2.

CHECK WITH ACTIVE TEST OF CONSULT

1.

Using CONSULT, perform “HVAC TEST” “ACTIVE TEST” of HVAC to check each output device. Refer to

.

NOTE:

Perform the ACTIVE TEST after starting the engine because the compressor is operated.

ZHA152H

JSIIA0999ZZ