содержание .. 762 763 764 765 ..

Nissan Murano. Manual - part 764

FRONT DRIVE SHAFT

FAX-51

< REMOVAL AND INSTALLATION >

[AWD]

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

Left Side

1.

Fix drive shaft with a vise.

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vise.

2.

Disassemble boot (wheel side). Refer to

FAX-49, "WHEEL SIDE : Disassembly and Assembly"

3.

Remove boot bands and boot (transaxle side).

Right Side

1.

Fix drive shaft with a vise.

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vise.

2.

Disassemble boot (wheel side). Refer to

FAX-49, "WHEEL SIDE : Disassembly and Assembly"

3.

Remove dynamic damper, follow the procedure described below.

a.

Remove damper bands.

b.

Remove dynamic damper from shaft.

4.

Remove boot bands and boot (transaxle side).

5.

Remove dust shield from housing assembly.

6.

Remove support bearing from link shaft, follow the procedure described below.

a.

Press out bearing housing and support bearing from link shaft.

b.

Remove dust shield from bearing housing.

c.

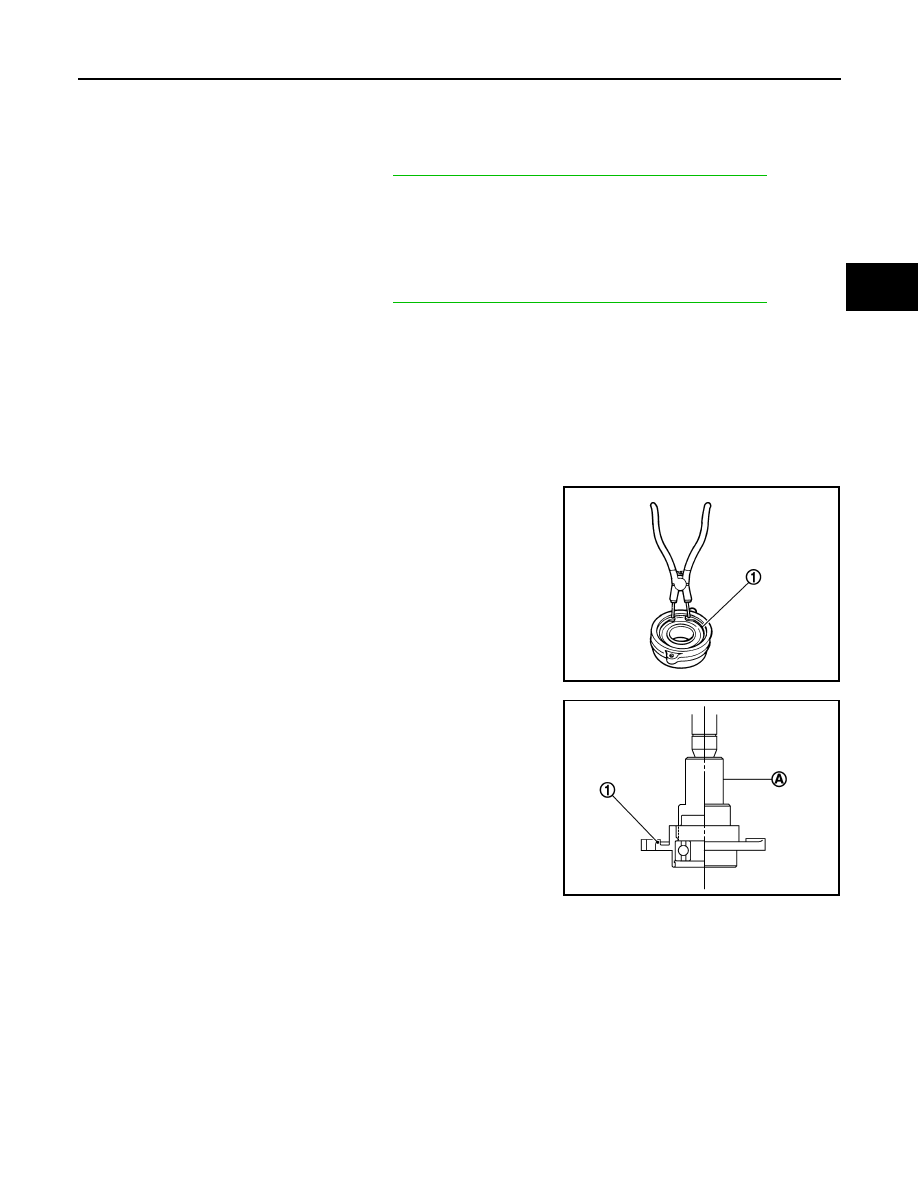

Remove snap ring (1).

d.

Remove oil seal.

e.

Press out support bearing from bearing housing (1) with drift (A)

[SST: ST17130000 (

—

)]

ASSEMBLY

Left Side

1.

Install dust shield.

CAUTION:

Never reuse dust shield.

2.

Install circular clip.

CAUTION:

Never reuse circular clip.

3.

Clean old grease on housing assembly with paper waste.

JPDIF0177ZZ

JPDIF0192ZZ