содержание .. 617 618 619 620 ..

Nissan Murano. Manual - part 619

EM-50

< REMOVAL AND INSTALLATION >

FUEL INJECTOR AND FUEL TUBE

1.

Remove radiator core support covers (RH and LH), air duct (inlet), air cleaner cases (upper and lower)

with mass air flow sensor and air duct assembly. Refer to

2.

Remove engine cover. Refer to

3.

Release the fuel pressure. Refer to

.

4.

Remove front wiper arm and extension cowl top. Refer to

5.

Drain engine coolant, or when water hoses are disconnected, attach plug to prevent engine coolant leak-

age. Refer to

CAUTION:

Perform this step when the engine is cold.

6.

Remove intake manifold collector. Refer to

7.

When separating fuel feed hose and fuel tube connection, disconnect quick connector as follows:

a.

Remove quick connector cap from quick connector.

b.

Disconnect quick connector from fuel tube as follows:

CAUTION:

Disconnect quick connector by using the quick connector release (commercial service tool: J-

45488), not by picking out retainer tabs.

i.

With the sleeve side of quick connector release facing to quick connector, install the quick connector

release onto fuel tube.

ii.

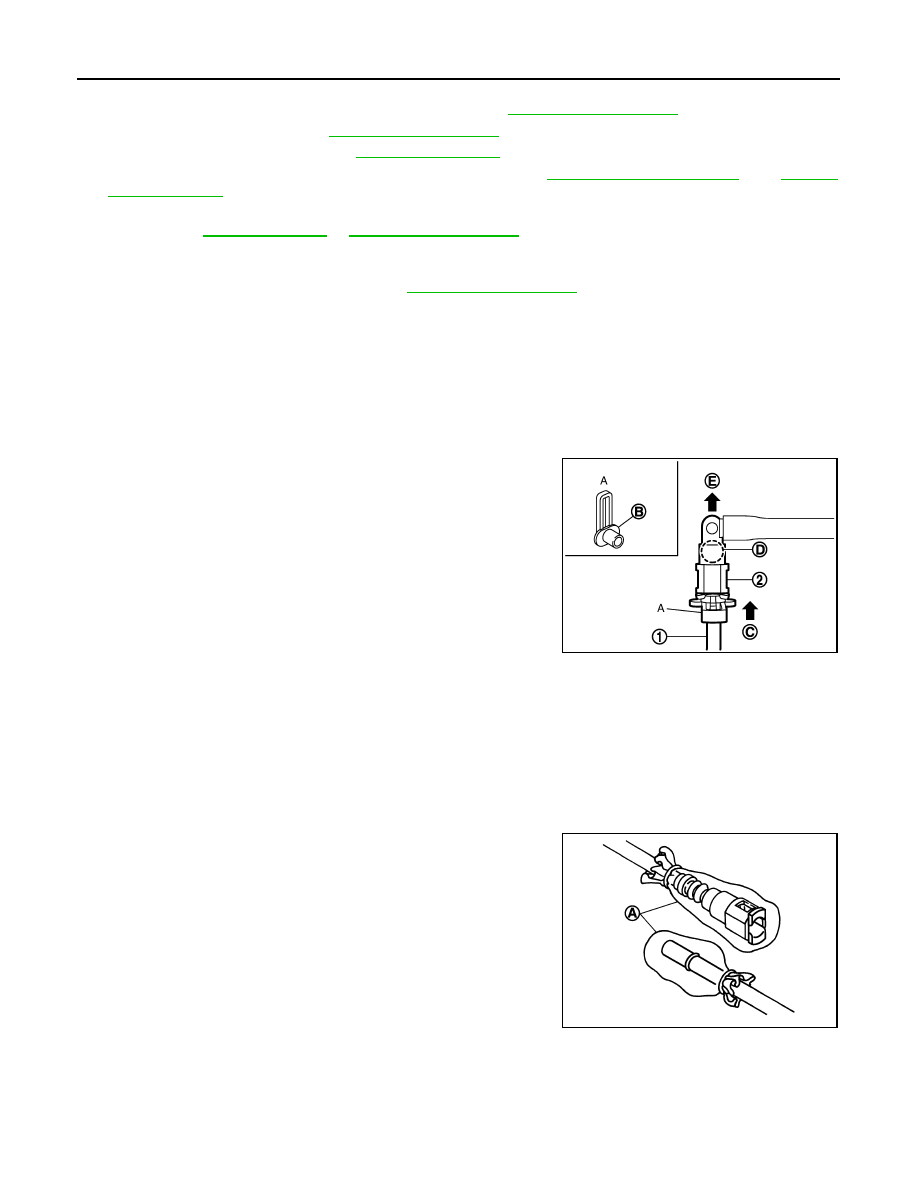

Insert the quick connector release (A) into quick connector (2)

until sleeve (B) contacts and goes no further. Hold quick connec-

tor release on that position.

CAUTION:

Inserting quick connector release hard will not disconnect

quick connector. Hold quick connector release where it

contacts and goes no further.

iii.

Draw and pull out quick connector straight from fuel tube (1).

CAUTION:

• Pull quick connector (E) holding position (D) as shown in

the figure.

• Never pull with lateral force applied. O-ring inside quick connector may be damaged.

• Prepare container and cloth beforehand as fuel will leakage out.

• Avoid fire and sparks.

• Keep parts away from heat source. Especially, be careful when welding is performed around

them.

• Never expose parts to battery electrolyte or other acids.

• Never bend or twist connection between quick connector and fuel feed hose (with damper) dur-

ing installation/removal.

• To keep clean the connecting portion and to avoid dam-

age and foreign materials, cover them completely with

plastic bags, etc. (A) or something similar.

8.

Disconnect harness connector from fuel injector.

C

: Insert and retain

JPBIA0033ZZ

JPBIA0035ZZ