содержание .. 516 517 518 519 ..

Nissan Murano. Manual - part 518

EC-182

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

P0116 ECT SENSOR

P0116 ECT SENSOR

Description

INFOID:0000000009719920

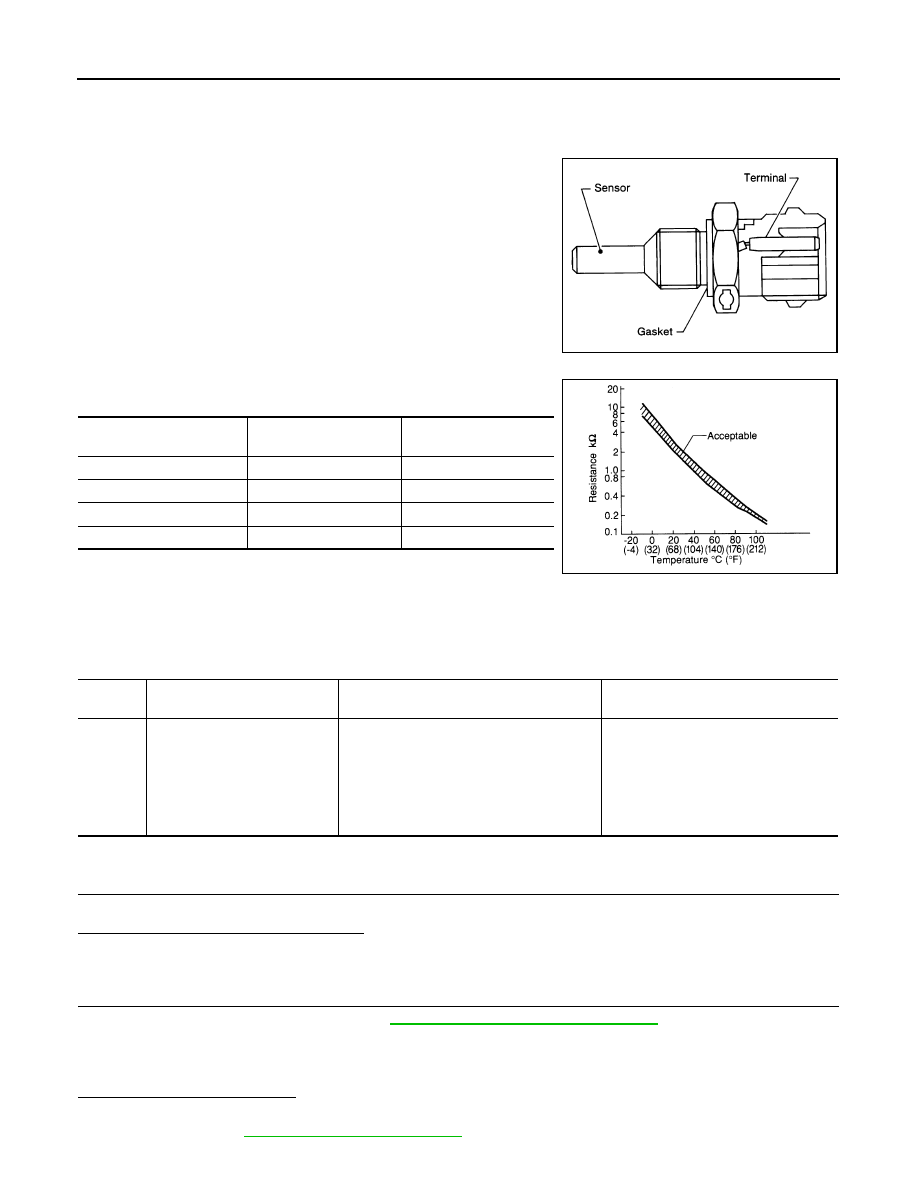

The engine coolant temperature sensor is used to detect the engine

coolant temperature. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the engine coolant

temperature input. The sensor uses a thermistor which is sensitive to

the change in temperature. The electrical resistance of the ther-

mistor decreases as temperature increases.

<Reference data>

*: These data are reference values and are measured between ECM terminals 46

(Engine coolant temperature sensor) and 52 (Sensor ground).

DTC Logic

INFOID:0000000009719921

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

INSPECTION START

Is it necessary to erase permanent DTC?

YES

>> GO TO 3.

NO

>> GO TO 2.

2.

PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to

EC-183, "Component Function Check"

NOTE:

Use the component function check to check the overall function of the ECT sensor circuit. During this check, a

1st trip DTC might not be confirmed.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Proceed to

.

SEF594K

Engine coolant temperature

[

°

C (

°

F)]

Voltage* (V)

Resistance (k

Ω

)

–10 (14)

4.4

7.0 - 11.4

20 (68)

3.5

2.1 - 2.9

50 (122)

2.2

0.68 - 1.00

90 (194)

0.9

0.236 - 0.260

SEF012P

DTC No.

Trouble diagnosis

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0116

ECT SEN/CIRC

[Engine coolant temperature

(ECT) sensor circuit range/per-

formance]

The comparison result of signals transmitted

to ECM from each temperature sensor (IAT

sensor, ECT sensor, FTT sensor, and EOT

sensor) shows that the voltage signal of the

ECT sensor is higher/lower than that of other

temperature sensors when the engine is

started with its cold state.

• Harness or connectors

(High or low resistance in the ECT

sensor circuit)

• ECT sensor