содержание .. 455 456 457 458 ..

Nissan Murano. Manual - part 457

DRIVE PINION

DLN-67

< UNIT DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY20A]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

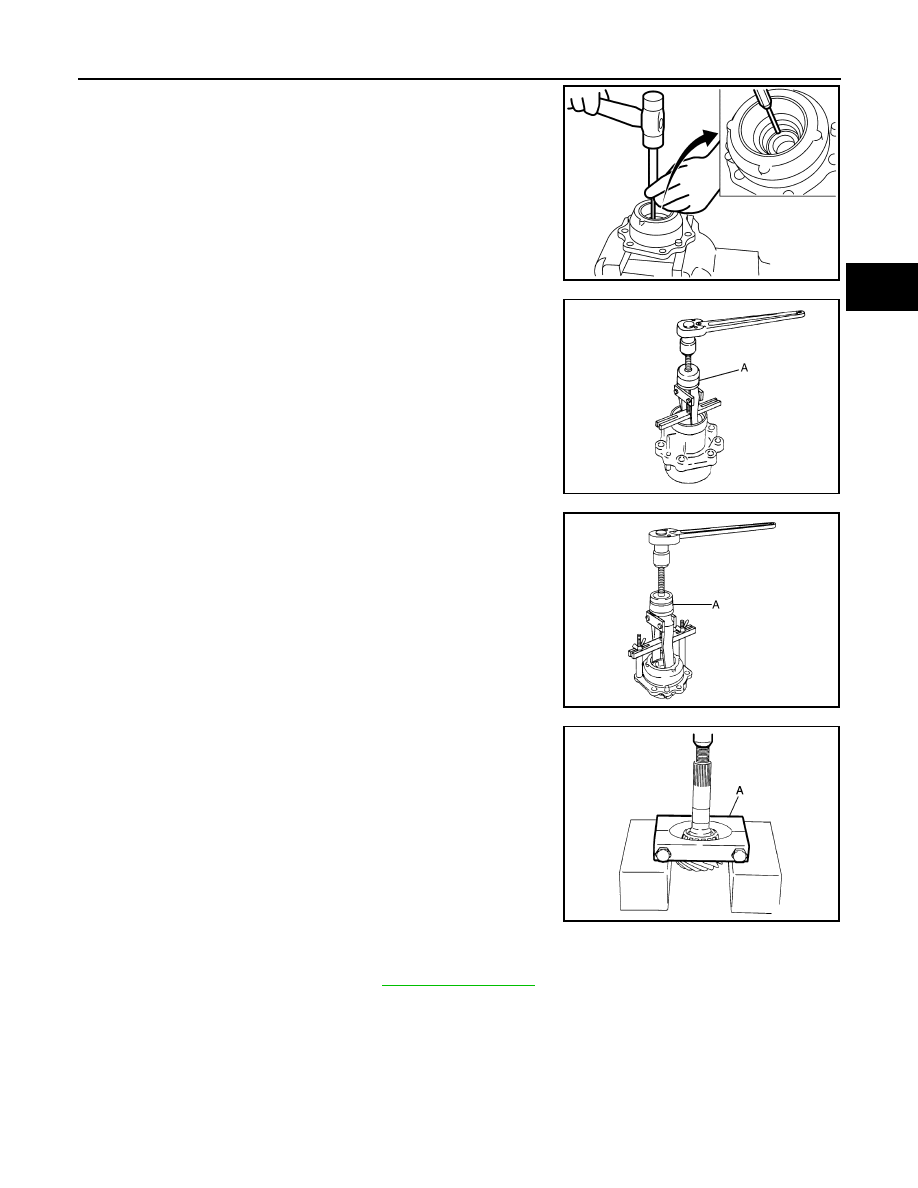

8.

Put out the circumference of pinion sleeve oil seal from back

side of pinion sleeve with punch to remove pinion sleeve oil

seal.

CAUTION:

When removing oil seal, never damage the pinion sleeve by

scooping it out with a tool.

9.

Remove pinion rear bearing inner race.

10. Remove the pinion rear bearing outer race with the puller (A)

[SST: KV381054S0 (J-34286)].

11. Remove the pinion front bearing outer race with the puller (A)

[SST: KV381054S0 (J-34286)].

12. Remove the collapsible spacer from the drive pinion.

13. Using the replacer (A) (commercial service tool), press the pin-

ion front bearing inner race out of the drive pinion.

Assembly

INFOID:0000000009718154

1.

Select the pinion sleeve shim. Refer to

JSDIA2345ZZ

JPDIE0026ZZ

JPDIE0027ZZ

JPDIE0028ZZ