содержание .. 454 455 456 457 ..

Nissan Murano. Manual - part 456

GEAR RING

DLN-63

< UNIT DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY20A]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

8.

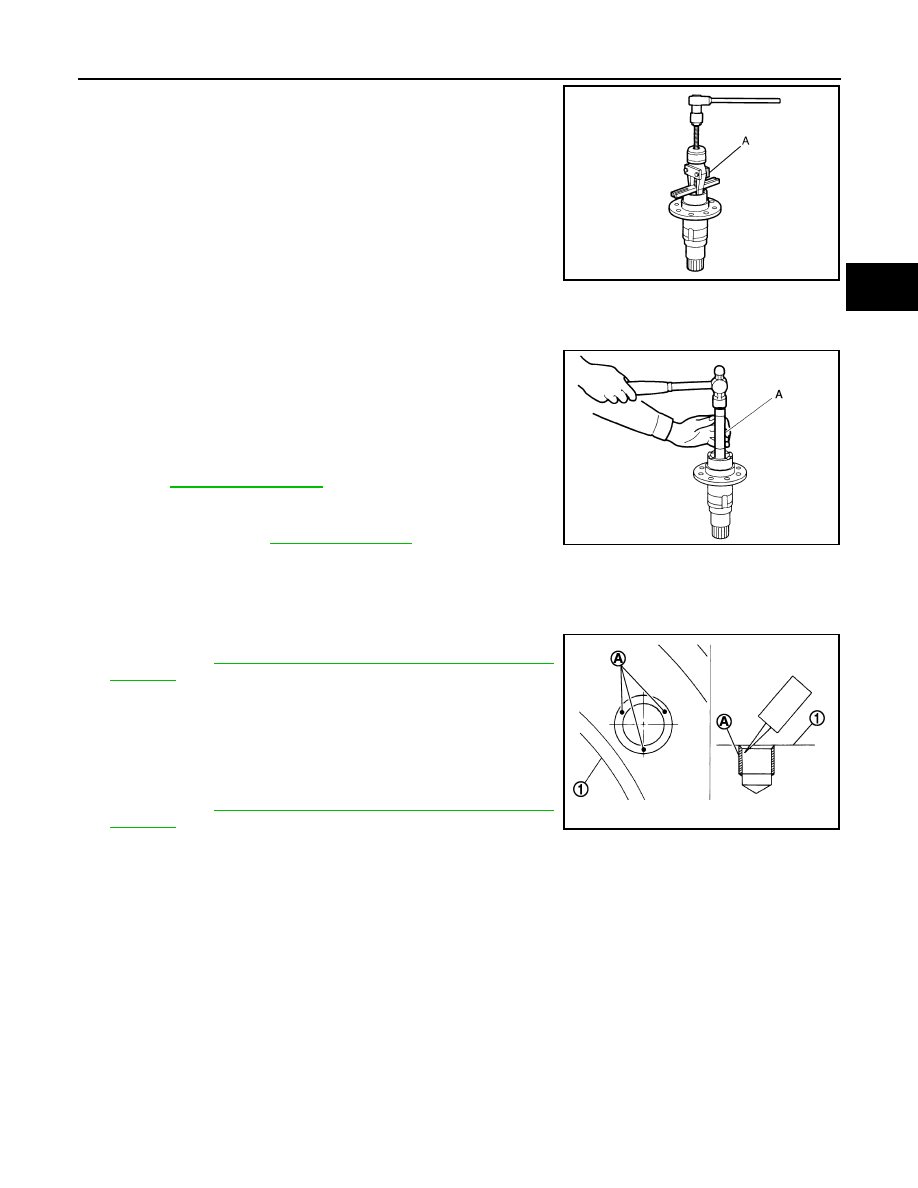

Remove gear ring oil seal from the gear ring with a puller (A)

[SST: KV381054S0 (J-34286)].

Assembly

INFOID:0000000009718150

1.

Install gear ring oil seal to the gear ring with the drift (A) [SST: ST33230000 (J-25805-01)].

Apply multi-purpose grease onto oil seal lips, and gear oil onto

the circumference of the oil seal.

CAUTION:

• Never reuse the oil seal.

• The oil seal back position after the installation shall be

56.5 mm (2.224 in) from the gear ring end.

2.

Select gear ring bearing adjusting shim (transfer case side).

Refer to

3.

Assemble the selected gear ring adjusting shim (transfer case

side) and gear ring bearing outer race (transfer case side) to the

transfer case. Refer to

Apply gear oil to the gear ring bearing (transfer case side).

CAUTION:

Never reuse gear ring bearing (transfer case side).

4.

Apply thread locking sealant into the thread hole for the drive gear (1).

Use Genuine High Strength Thread Locking Sealant or equiva-

lent. Refer to

GI-22, "Recommended Chemical Products and

.

a.

Completely clean and degrease the drive gear back face, thread

holes, and drive gear mounting bolts.

b.

Apply thread locking sealant onto the first and second threads

under the thread hole chamfering of the drive gear on 3 or more

different points (A).

Use Genuine High Strength Thread Locking Sealant or equiva-

lent. Refer to

GI-22, "Recommended Chemical Products and

.

5.

Install the drive gear to gear ring, and apply anti-corrosive oil

onto threads and seats on the mounting bolts.

CAUTION:

If the thread locking sealant is applied aside, quickly wipe it off.

6.

The drive gear mounting bolts are tightened according to the following torque.

CAUTION:

Temporary installation before tightening the bolts through to the completion of the tightening

should be within 90 seconds.

JPDIE0032ZZ

JPDIE0037ZZ

1st step

: 27 N·m (2.8 kg-m, 20 ft-lb)

2nd step

: 98.5 N·m (10 kg-m, 73 ft-lb)

JPDIE0038ZZ