содержание .. 262 263 264 265 ..

Nissan Murano. Manual - part 264

CHG-12

< SYSTEM DESCRIPTION >

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

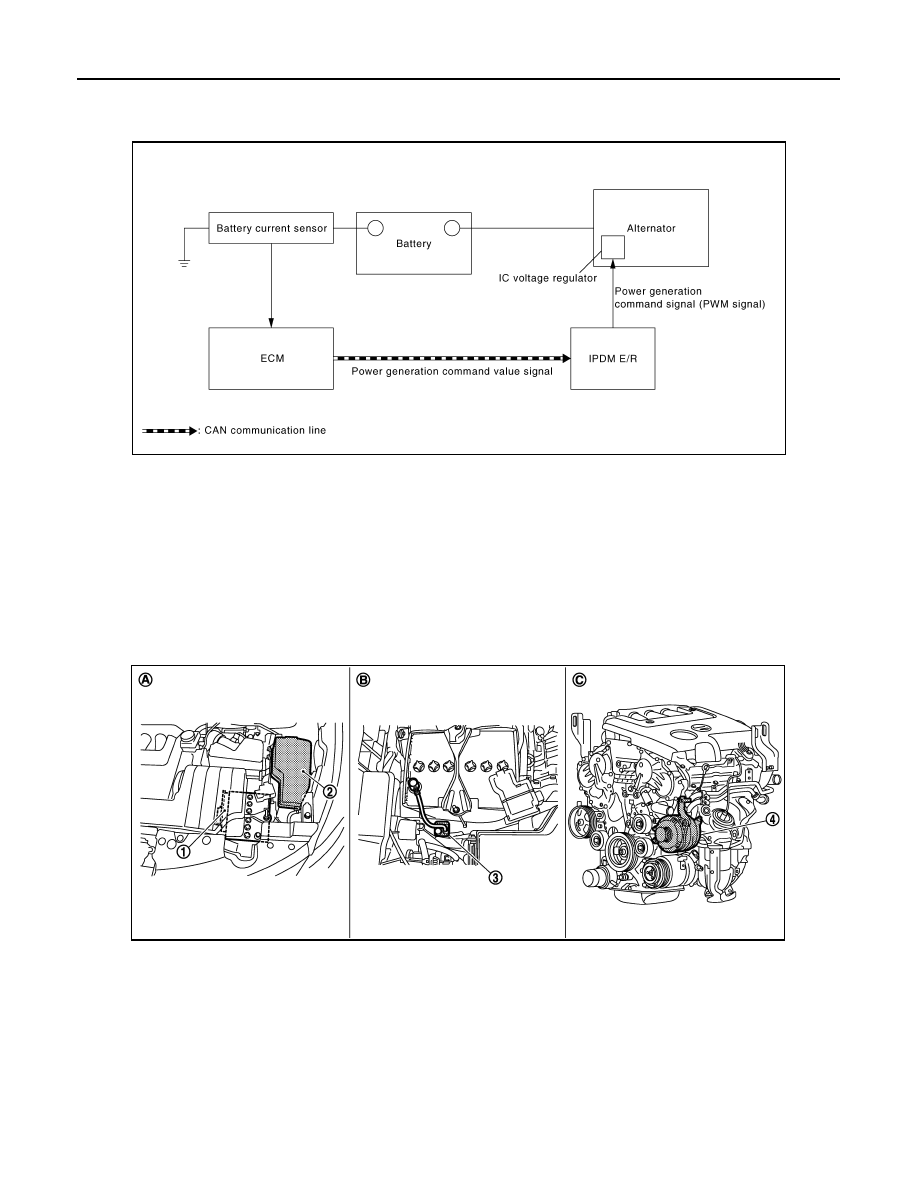

System Diagram

INFOID:0000000009722543

System Description

INFOID:0000000009722544

By performing the power generation voltage variable control, the engine load due to the power generation of

the alternator is reduced and fuel consumption is decreased.

NOTE:

When any malfunction is detected in the power generation voltage variable control system, the power genera-

tion is performed according to the characteristic of the IC voltage regulator of the alternator.

Component Parts Location

INFOID:0000000009722545

JMMIA1072GB

1.

ECM

2.

IPDM E/R

3.

Battery current sensor

4.

Alternator

A.

Engine room dash panel (LH)

B.

Battery

C.

Cylinder block left side

JPLIA0888ZZ