содержание .. 225 226 227 228 ..

Nissan Murano. Manual - part 227

BRC-64

< DTC/CIRCUIT DIAGNOSIS >

[VDC/TCS/ABS]

C1140 ACTUATOR RELAY SYSTEM

C1140 ACTUATOR RELAY SYSTEM

Description

INFOID:0000000009718281

Activates or deactivates each valve according to the signals transmitted by the ABS actuator and electric unit

(control unit).

DTC Logic

INFOID:0000000009718282

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn the ignition switch OFF

and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

DTC REPRODUCTION PROCEDURE

1.

Turn the ignition switch OFF to ON.

2.

Perform self-diagnosis for “ABS” with CONSULT.

Is DTC “C1140” detected?

YES

>> Proceed to diagnosis procedure. Refer to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000009718283

1.

CHECK CONNECTOR

1.

Turn the ignition switch OFF.

2.

Disconnect ABS actuator and electric unit (control unit) harness connector.

3.

Check the terminal for deformation, disconnection, looseness, etc.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace error-detected parts.

2.

CHECK ACTUATOR RELAY POWER SUPPLY

1.

Check the voltage between ABS actuator and electric unit (control unit) harness connector and ground.

2.

Turn the ignition switch ON.

CAUTION:

Never start the engine.

3.

Check the voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal?

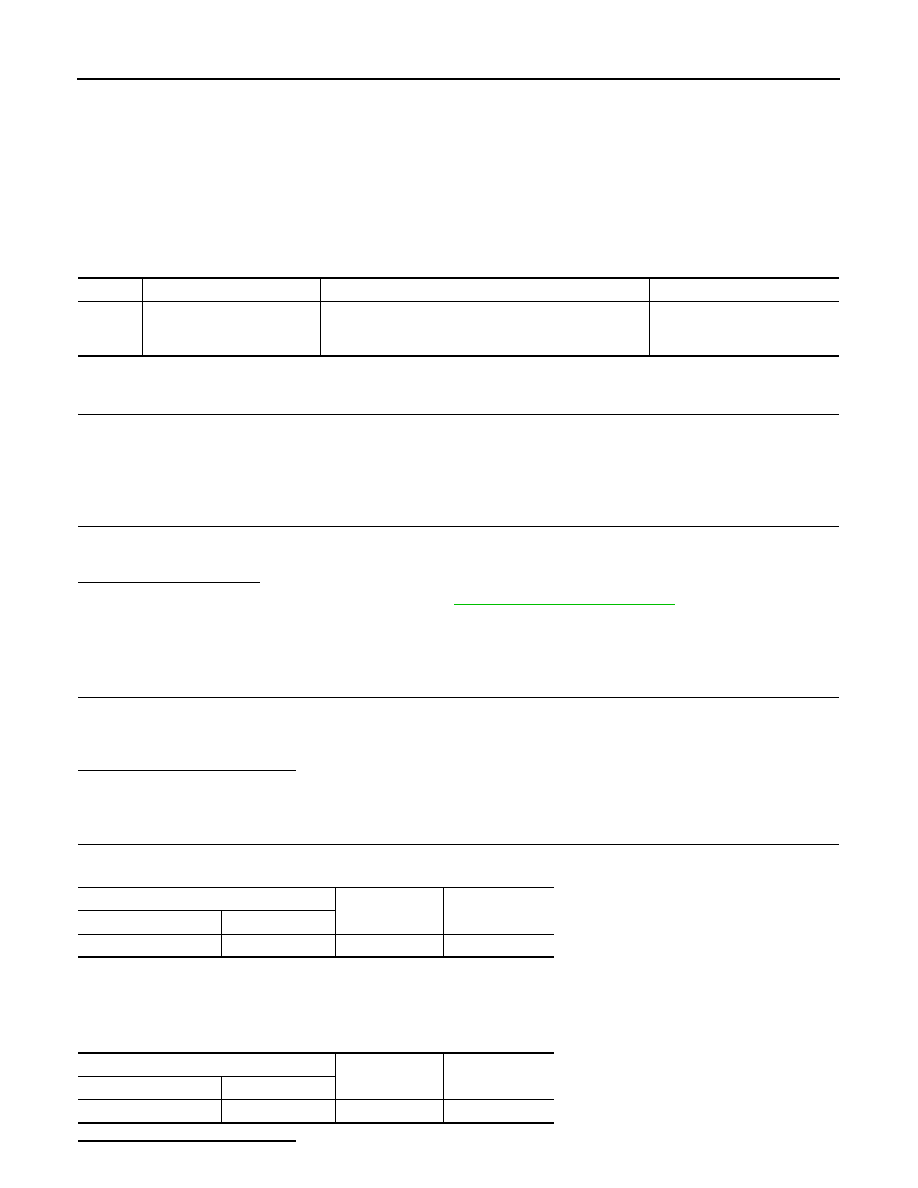

DTC

Display item

Malfunction detected condition

Possible cause

C1140

ACTUATOR RLY

When the control unit detects a malfunction in the actua-

tor relay system.

• Harness or connector

• ABS actuator and electric unit

(control unit)

ABS actuator and electric unit (control unit)

—

Voltage

(Approx.)

Connector

Terminal

E36

1

Ground

Battery voltage

ABS actuator and electric unit (control unit)

—

Voltage

(Approx.)

Connector

Terminal

E36

1

Ground

Battery voltage