содержание .. 907 908 909 910 ..

Nissan X-Trail 32. Manual - part 909

P2135 TP SENSOR

EC-765

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

2.

Also check harness for short to ground and to power.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.

CHECK THROTTLE POSITION SENSOR

Check the throttle position sensor. Refer to

EC-765, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Replace electric throttle control actuator. Refer to

EM-176, "Removal and Installation"

.

7.

CHECK INTERMITTENT INCIDENT

GI-44, "Intermittent Incident"

.

>> INSPECTION END

Component Inspection

INFOID:0000000010986473

1.

CHECK THROTTLE POSITION SENSOR

1.

Turn ignition switch OFF.

2.

Reconnect all harness connectors disconnected.

3.

Perform “ Throttle Valve Closed Position Learning”. Refer to

4.

Turn ignition switch ON.

5.

Set selector lever to D position.

6.

Check the voltage between ECM harness connector terminals as per the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace electric throttle control actuator. Refer to

EM-176, "Removal and Installation"

.

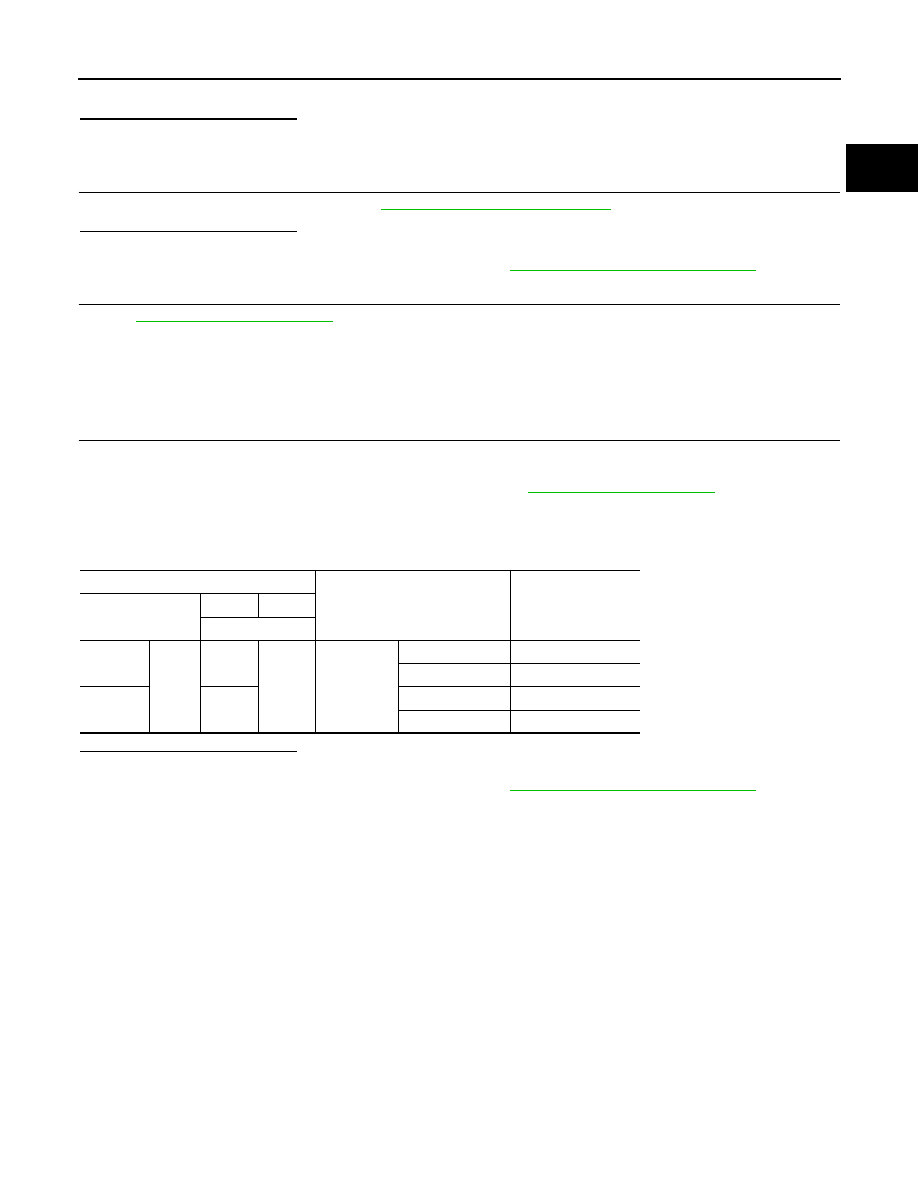

ECM

Condition

Voltage

Connector

+

−

Terminal

Sensor 1

F68

79

78

Accelerator

pedal

Fully released

More than 0.36V

Fully depressed

Less than 4.75V

Sensor 2

77

Fully released

Less than 4.75V

Fully depressed

More than 0.36V