содержание .. 694 695 696 697 ..

Nissan X-Trail 32. Manual - part 696

DRIVE PINION

DLN-195

< UNIT DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY30A]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

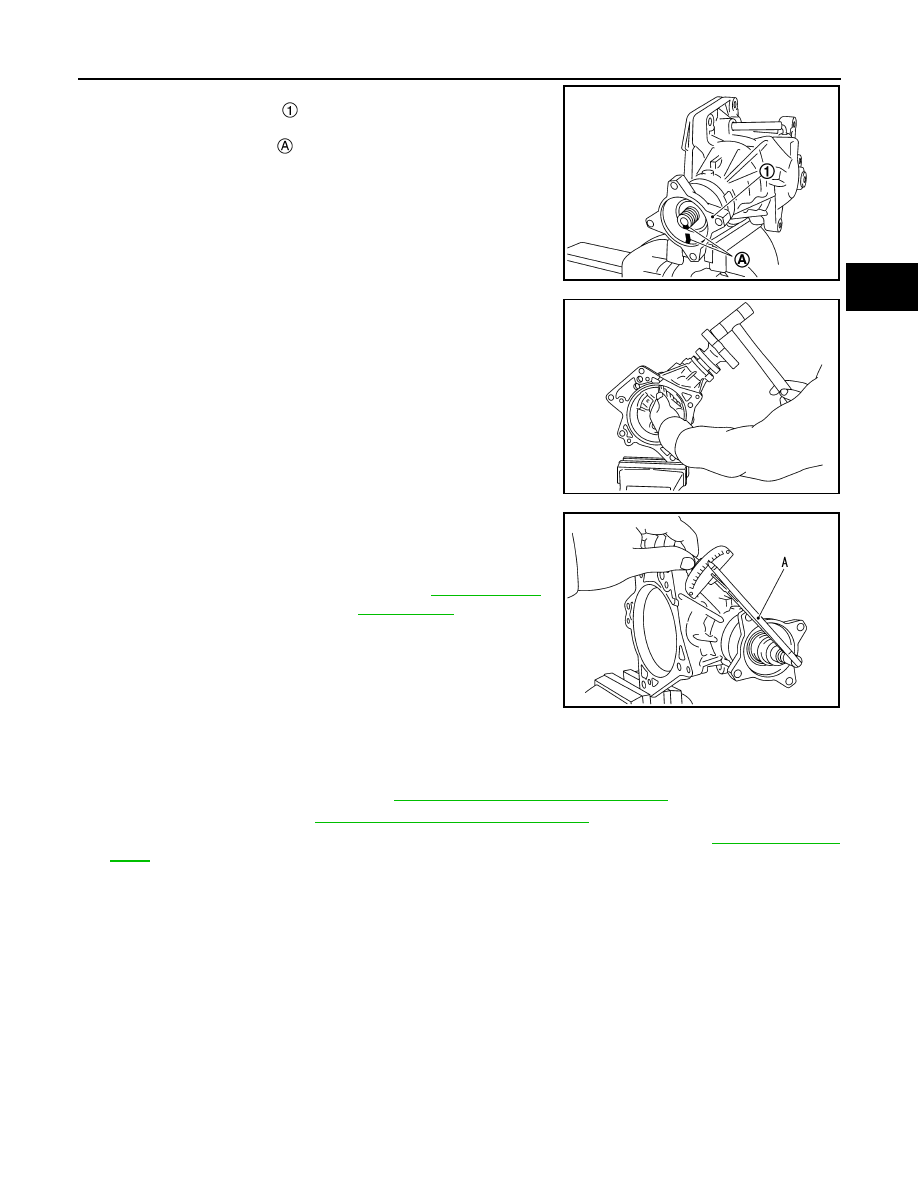

7.

Assemble drive pinion assembly into the transfer case, and then

install companion flange

to drive pinion.

NOTE:

Align matching marks

on the thread edge of companion

flange and drive pinion and install companion flange if drive pin-

ion is reused.

8.

Tap the companion flange with a plastic hammer as far as the

lock nut can be tightened.

CAUTION:

Never damage drive pinion oil seal.

9.

Apply anti-corrosive oil to the thread and seat of the lock nut,

and temporarily tighten lock nut to the drive pinion.

CAUTION:

Never reuse lock nut.

10. Tighten lock nut within the specified torque range with a preload

gauge (A) (SST: ST3127S000) so that the drive pinion bearing

preload is within standard.

CAUTION:

• Start the tightening of lock nut from lower limit of the

specified torque. Check the preload every 5

°

to 10

°

while

tightening the lock nut.

• Replace the collapsible spacer and tighten it again to

adjust if preload exceeds the specified value. Never

loosen lock nut to adjust preload.

• After adjustment, rotate the drive pinion back and forth from 2 to 3 times to check for unusual

noise, sticking, binding, and so on.

11. Install ring gear shaft assembly. Refer to

DLN-188, "Disassembly and Assembly"

.

12. Install adapter case. Refer to

DLN-185, "Disassembly and Assembly"

.

13. Check backlash, tooth contact, total preload and companion flange runout. Refer to

.

CAUTION:

Measure the total preload without the adapter case oil seal.

Adjustment

INFOID:0000000011005062

BACKLASH

1.

Install the bolt to the companion flange.

SDIA3084J

SDIA3095J

Drive pinion bearing preload

: Refer to

SDIA3072J