содержание .. 281 282 283 284 ..

Nissan X-Trail 32. Manual - part 283

CHG-48

< SERVICE DATA AND SPECIFICATIONS (SDS)

[TYPE 2]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

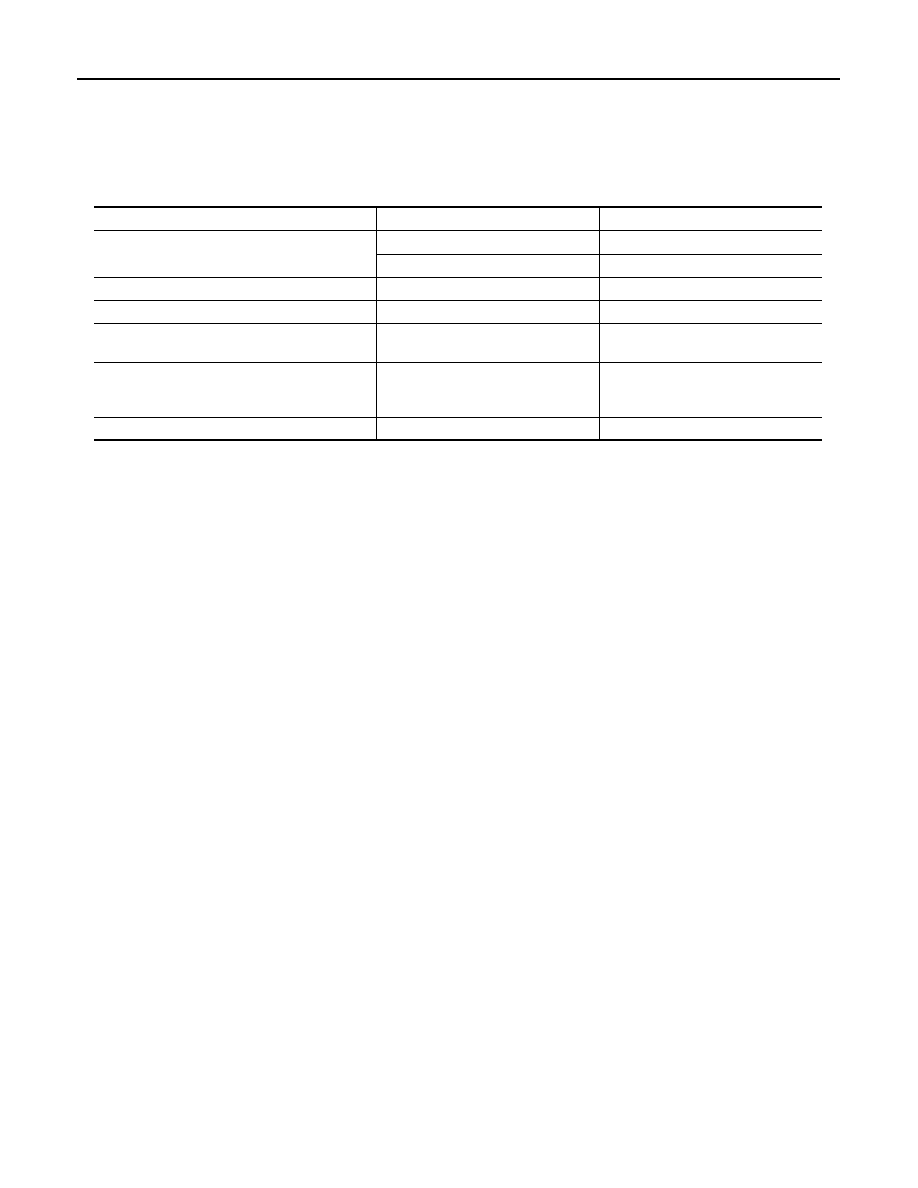

Alternator

INFOID:0000000010957591

Applied model

MR engine

QR engine

Type

2620093

2620168

Valeo Make

Valeo Make

Nominal rating

[V - A]

12 - 120

12 - 120

Ground polarity

Negative

Negative

Minimum revolution under no-load

(When 13.5 V is applied)

[rpm]

Less than 1,200

Less than 1,200

Hot output current

(When 13.5 V is applied)

[A/rpm]

More than 46/1,500

More than 96/2,500

More than 117/5,000

More than 46/1,500

More than 96/2,500

More than 117/5,000

Regulated output voltage

[V]

14.0 – 14.6

14.0 – 14.6