содержание .. 2167 2168 2169 2170 ..

Nissan X-Trail 32. Manual - part 2169

TM-634

< DTC/CIRCUIT DIAGNOSIS >

[CVT: RE0F10G]

P188E ELECTRIC OIL PUMP

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace malfunctioning parts.

5.

CHECK ELECTRIC OIL PUMP RELAY SIGNAL

1.

Install the electric oil pump relay.

2.

Connect the TCM connector.

3.

Check the voltage between the TCM harness connector terminal and ground.

Is the inspection result normal?

YES

>> GO TO 6.

NO

TM-676, "Removal and Installation"

6.

CHECK TCM COMMAND SIGNAL

With CONSULT

1.

Turn ignition switch ON.

2.

Select “Data Monitor” in “TRANSMISSION”.

3.

Select “ELECTRIC OP DUTY”.

4.

Start the engine.

5.

Drive the vehicle and maintain the following condition.

6.

Activate stop/start system. Refer to.

EC-856, "STOP/START SYSTEM : System Description (CVT mod-

Is the inspection result normal?

YES

>> GO TO 7.

NO

TM-676, "Removal and Installation"

7.

CHECK ELECTRIC OIL PUMP STATUS SIGNAL

With CONSULT

1.

Turn ignition switch OFF.

2.

Turn ignition switch ON.

3.

Select “E-OP DUTY MON”.

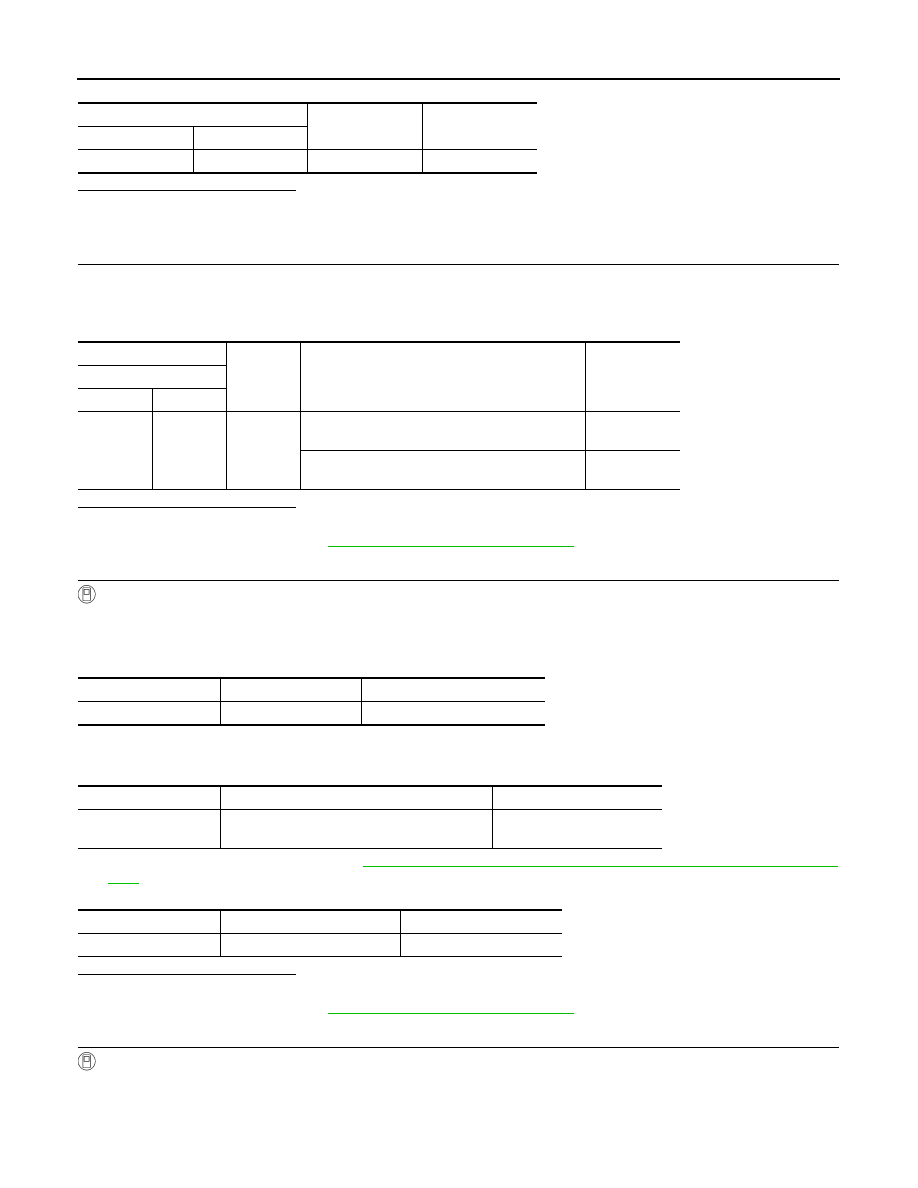

Electric oil pump relay

—

Continuity

Connector

Terminal

F66

2

Ground

Not existed

+

−

Condition

Voltage

TCM

Connector

Terminal

F119

1

Ground

• Selector lever: “D”position

• Vehicle speed: 11 km/h (7 MPH) or more

10 – 16 V

• Selector lever: “D”position

• Vehicle speed: 6 km/h (3 MPH) or less

Approx. 0 V

Monitor item

Condition

Reference value/Status

ELECTRIC OP DUTY

Ignition switch: ON

5 – 15%

Monitor item

Condition

Reference value/Status

ELECTRIC OP DUTY

• Selector lever: “D”position

• Vehicle speed: 11 km/h (7 MPH) or more

5 – 15%

Monitor item

Condition

Reference value/Status

ELECTRIC OP DUTY

Stop/start system operating

55 – 85%