содержание .. 2166 2167 2168 2169 ..

Nissan X-Trail 32. Manual - part 2168

TM-630

< DTC/CIRCUIT DIAGNOSIS >

[CVT: RE0F10G]

P1588 G SENSOR

YES

>> Go to

NO-1

>> To check malfunction symptom before repair: Refer to

GI-44, "Intermittent Incident"

.

NO-2

>> Confirmation after repair: INSPECTION END

Diagnosis Procedure

INFOID:0000000010646393

1.

CHECK G SENSOR SIGNAL

With CONSULT

1.

Park the vehicle on a level surface.

2.

Turn ignition switch ON.

3.

Select “Data Monitor” in “TRANSMISSION”

4.

Select “G SEN SLOPE”.

5.

Swing the vehicle and check if value varies between

−

40.45% and 40.45%.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

G SENSOR CALIBRATION (PART 1)

With CONSULT

1.

Select “Self Diagnostic Results” in “TRANSMISSION”.

2.

Touch “Erase”.

>> Perform “G SENSOR CALIBRATION”. Refer to

3.

CHECK G SENSOR

1.

Remove G sensor.

TM-678, "Removal and Installation"

.

2.

Connect the all connectors.

3.

Turn ignition switch ON.

4.

Check voltage between TCM harness connector terminal and

ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Replace G sensor.

TM-678, "Removal and Installation"

.

4.

G SENSOR CALIBRATION (PART 2)

With CONSULT

1.

Install G sensor.

TM-678, "Removal and Installation"

.

2.

Select “Self Diagnostic Results” in “TRANSMISSION”.

3.

Touch “Erase”.

Monitor item

Condition

Standard

G SEN SLOPE

Flat road

0%

Uphill

Positive value (Maximum 40.45%)

Downhill

Negative value (Minimum

−

40.45%)

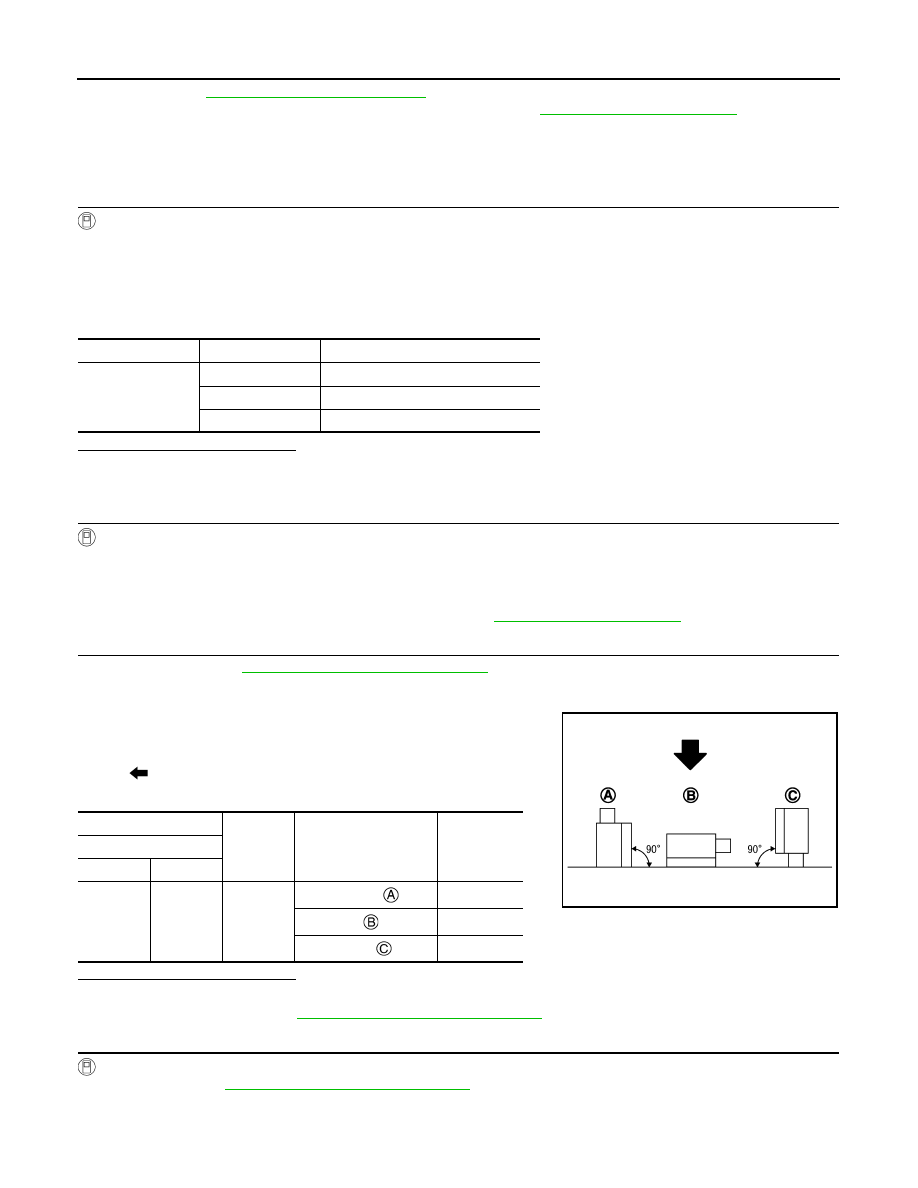

: Direction of gravitational force

+

−

Test condition

Voltage (Ap-

prox.)

TCM

Connector

Terminal

F119

14

Ground

Vertical (

−

1G)

1.17 V

Horizontal

2.5 V

Vertical (1G)

3.83 V

SCIA8343J