содержание .. 2093 2094 2095 2096 ..

Nissan X-Trail 32. Manual - part 2095

TM-338

< DTC/CIRCUIT DIAGNOSIS >

[CVT: RE0F10D]

P0717 INPUT SPEED SENSOR A

4.

Stop the vehicle.

5.

Check the first trip DTC.

Is “P0717” detected?

YES

>> Go to

NO-1

>> To check malfunction symptom before repair: Refer to

GI-44, "Intermittent Incident"

.

NO-2

>> Confirmation after repair: INSPECTION END

Diagnosis Procedure

INFOID:0000000010622525

1.

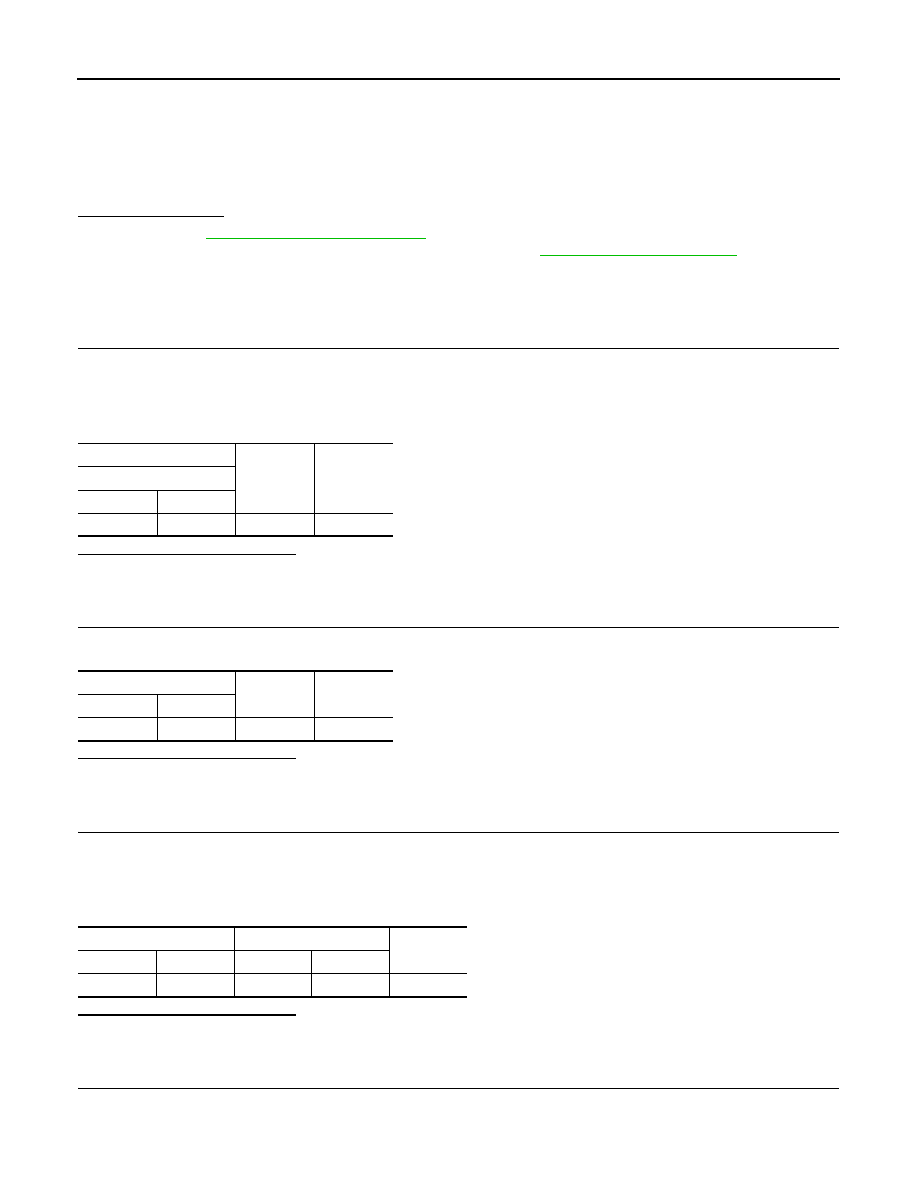

CHECK INPUT SPEED SENSOR POWER CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect input speed sensor connector.

3.

Turn ignition switch ON.

4.

Check voltage between input speed sensor harness connector terminal and ground.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> GO TO 6.

2.

CHECK INPUT SPEED SENSOR GROUND CIRCUIT

Check continuity between input speed sensor harness connector terminal and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace malfunctioning parts.

3.

CHECK CIRCUIT BETWEEN INPUT SPEED SENSOR AND TCM (PART 1)

1.

Turn ignition switch OFF.

2.

Disconnect TCM connector.

3.

Check continuity between input speed sensor harness connector terminal and TCM harness connector

terminal.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace malfunctioning parts.

4.

CHECK CIRCUIT BETWEEN INPUT SPEED SENSOR AND TCM (PART 2)

Check continuity between input speed sensor harness connector terminal and ground.

Selector lever

: “D” position

Engine speed

: 1,200 rpm or more

Vehicle speed

: 40 km/h (25 MPH) or more

+

−

Voltage

Input speed sensor

Connector

Terminal

F54

3

Ground

10 – 16 V

Input speed sensor

—

Continuity

Connector

Terminal

F54

1

Ground

Existed

Input speed sensor

TCM

Continuity

Connector

Terminal

Connector

Terminal

F54

2

F23

24

Existed