содержание .. 1559 1560 1561 1562 ..

Nissan X-Trail 32. Manual - part 1561

MA-34

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE (MR20DD)

1.

Check the engine oil level. Refer to

.

2.

Start the engine, and check there is no leakage of engine oil.

3.

Stop the engine and wait for 10 minutes.

4.

Check the engine oil level, and adjust the level. Refer to

.

SPARK PLUG

SPARK PLUG : Removal and Installation

INFOID:0000000011009171

REMOVAL

1.

Remove resonater of air duct assembly. Refer to

2.

Remove ignition coil. Refer to

.

3.

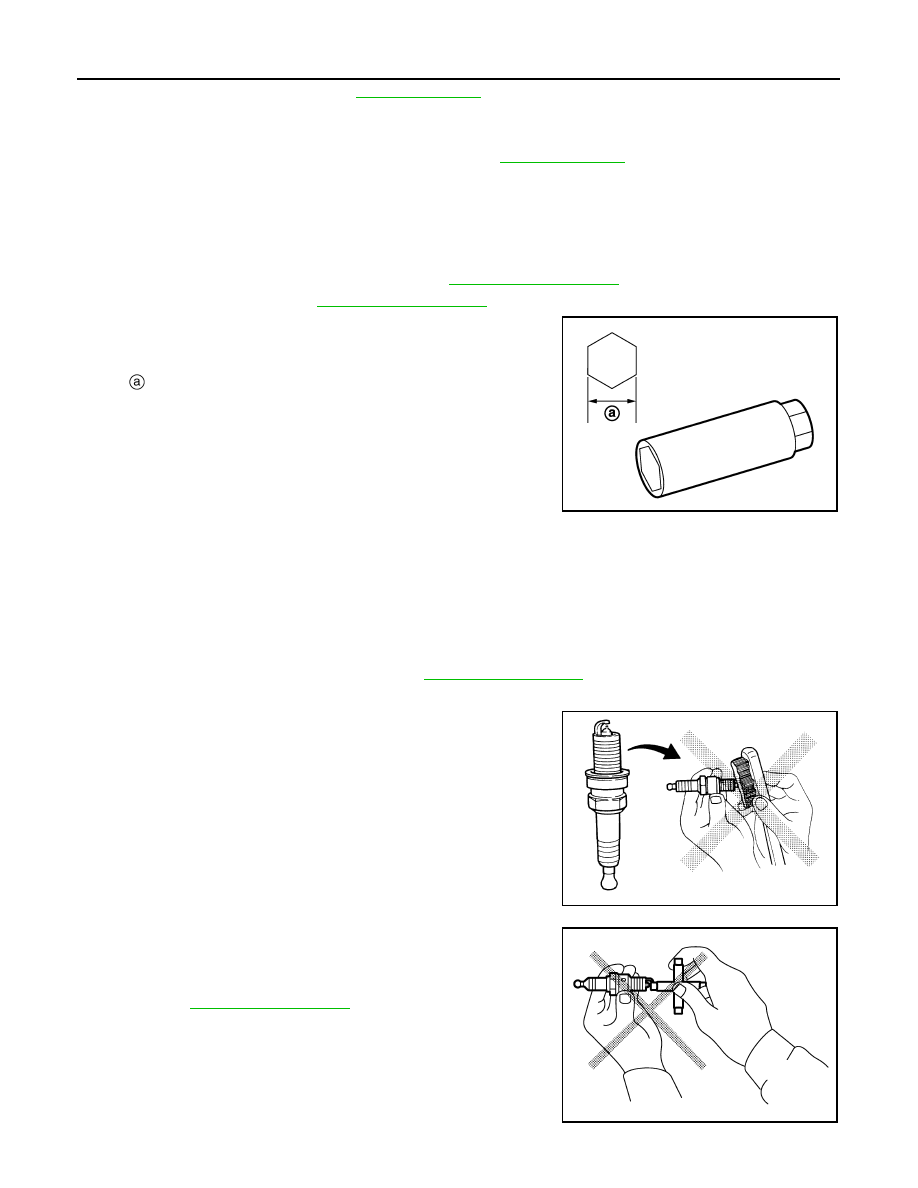

Remove spark plug with a spark plug wrench (commercial ser-

vice tool).

CAUTION:

Never drop or shock spark plug.

INSTALLATION

Install in the reverse order of removal.

SPARK PLUG : Inspection

INFOID:0000000011009172

INSPECTION AFTER REMOVAL

Use the standard type spark plug for normal condition.

CAUTION:

• Never drop or shock spark plug.

• Never use a wire brush for cleaning.

• If plug tip is covered with carbon, spark plug cleaner may be

used.

• Checking and adjusting plug gap is not required between

replacement intervals.

• Measure spark plug gap. when it exceeds the limit, replace

spark plug even if it is with in the specified replacement mile-

age. Refer to

.

EVAP VAPOR LINES

: 14 mm (0.55 in)

JPBIA0030ZZ

Spark plug (Standard type)

: Refer to

.

Cleaner air pressure

: Less than 588 kPa (5.88 bar, 6

kg/cm

2

, 85 psi)

Cleaning time

: Less than 20 seconds

SMA773C

JPBIA0031ZZ