содержание .. 1432 1433 1434 1435 ..

Nissan X-Trail 32. Manual - part 1434

MAGNET CLUTCH

HAC-211

< DTC/CIRCUIT DIAGNOSIS >

[MANUAL AIR CONDITIONING]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

Is the inspection result normal?

YES

>> Replace compressor. Refer to

HA-30, "Removal and Installation"

Russia) or

HA-76, "Removal and Installation"

(MR20DD engine models).

NO

>> Repair harness or connector.

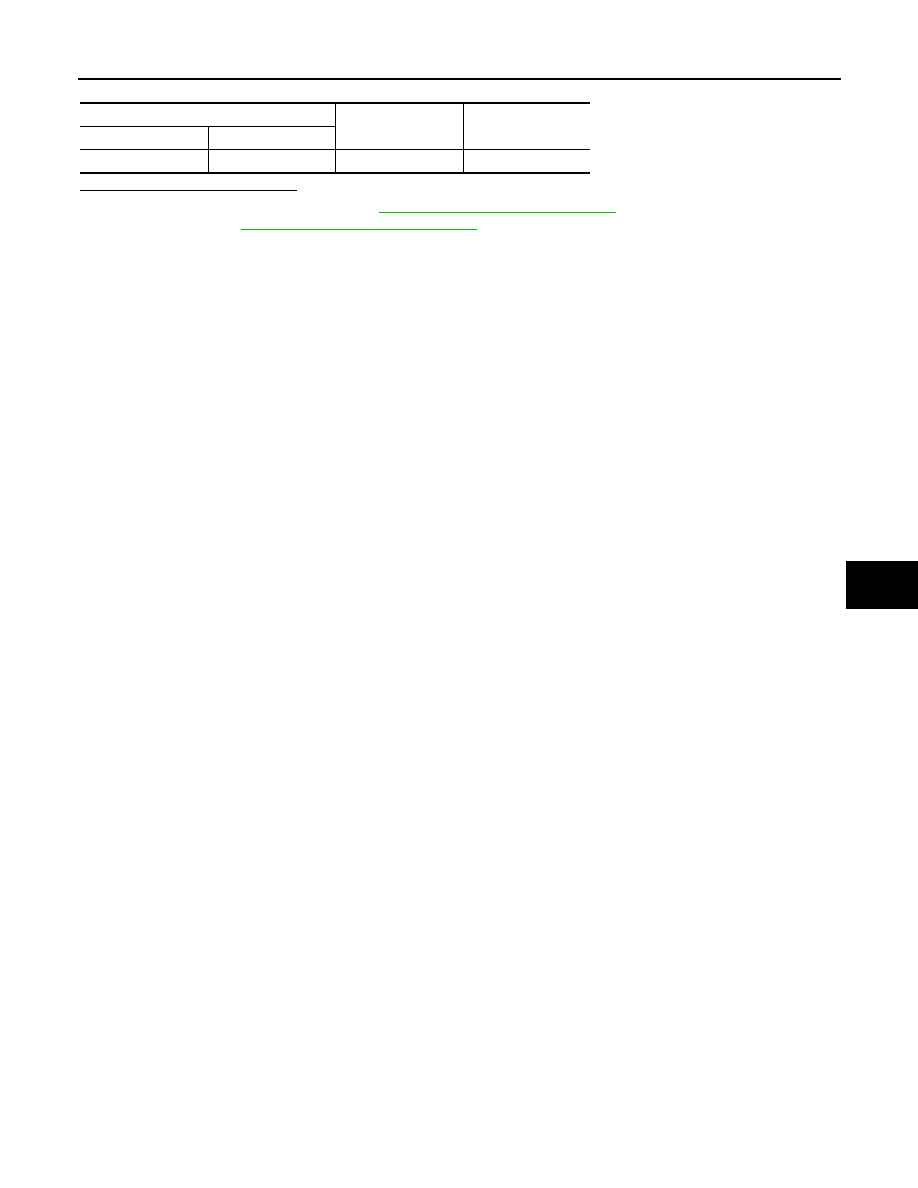

Compressor

—

Continuity

Connector

Terminal

F17

2

Ground

Existed