содержание .. 1358 1359 1360 1361 ..

Nissan X-Trail 32. Manual - part 1360

PRECAUTIONS

HA-99

< PRECAUTION >

[QR25DE]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

NOTE:

Identification

• Vehicles with factory installed fluorescent dye have a green label.

• Vehicles without factory installed fluorescent dye have a blue label.

Service Equipment

INFOID:0000000011006047

RECOVERY/RECYCLING RECHARGING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

ELECTRICAL LEAK DETECTOR

Be certain to follow the manufacturer’s instructions for tester operation and tester maintenance.

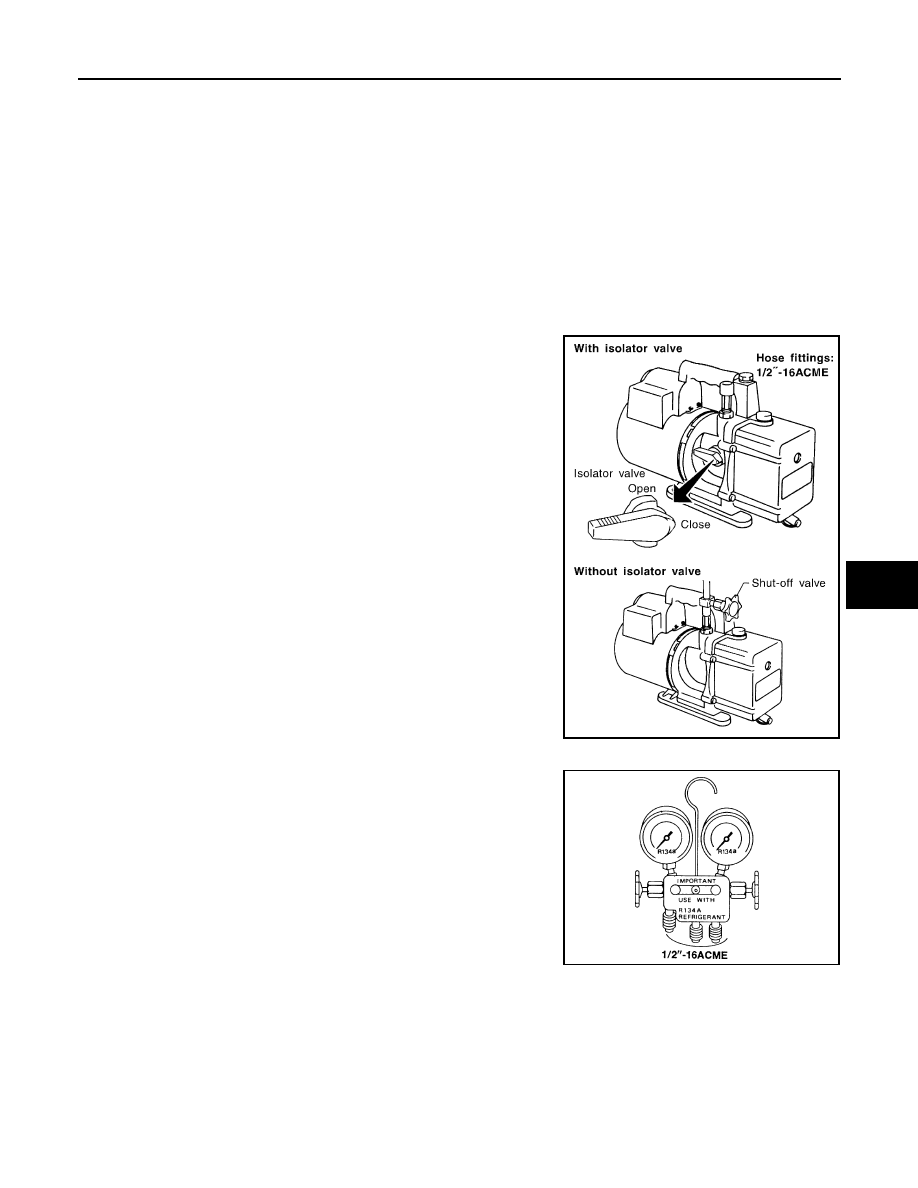

VACUUM PUMP

The lubricant contained inside the vacuum pump is not compatible

with the specified lubricant for HFC-134a (R-134a) A/C systems.

The vent side of the vacuum pump is exposed to atmospheric pres-

sure. So the vacuum pump lubricant may migrate out of the pump

into the service hose. This is possible when the pump is switched

OFF after evacuation (vacuuming) and hose is connected to it.

To prevent this migration, use a manual valve placed near the hose-

to-pump connection, as per the following.

• Vacuum pumps usually have a manual isolator valve as part of the

pump. Close this valve to isolate the service hose from the pump.

• Use a hose equipped with a manual shut-off valve near the pump

end for pumps without an isolator. Close the valve to isolate the

hose from the pump.

• Disconnect the hose from the pump if the hose has an automatic

shut-off valve. As long as the hose is connected, the valve is open

and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2

″

-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified lubricants.

SERVICE HOSES

RHA270DA

SHA533D