содержание .. 1356 1357 1358 1359 ..

Nissan X-Trail 32. Manual - part 1358

A/C UNIT ASSEMBLY

HA-91

< REMOVAL AND INSTALLATION >

[MR20DD]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

HEATER CORE : Removal and Installation

INFOID:0000000011001073

REMOVAL

1.

Remove A/C unit assembly. Refer to

HA-88, "A/C UNIT ASSEMBLY : Removal and Installation"

.

2.

Remove foot duct LH. Refer to

VTL-12, "FOOT DUCT : Removal and Installation"

.

3.

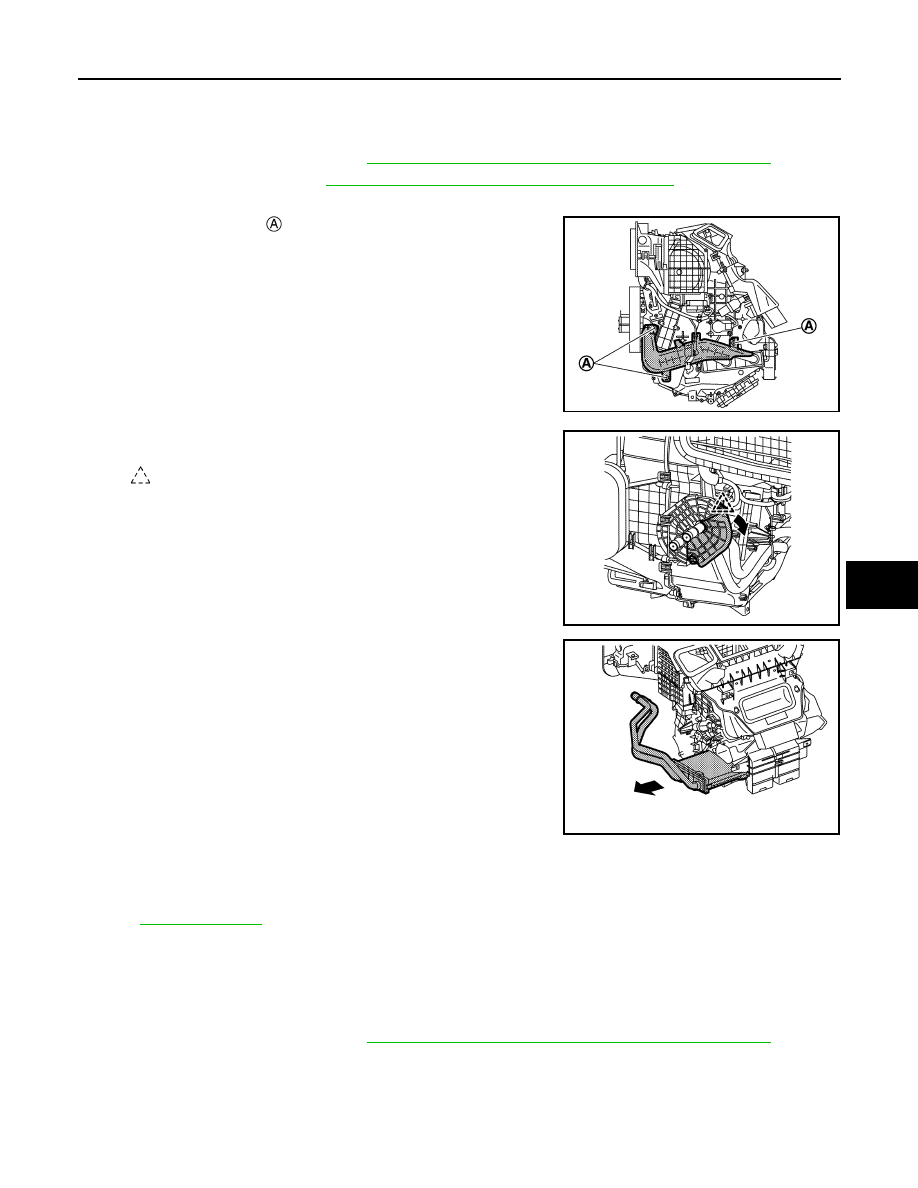

Remove heater pipe grommet.

4.

Remove fixing screws

, and then remove heater pipe cover.

5.

Disengage fixing pawl, and then remove heater pipe bracket.

6.

Slide heater core to left side, and then remove heater core.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

NOTE:

Refer to

when filling radiator with engine coolant.

EVAPORATOR

EVAPORATOR : Removal and Installation

INFOID:0000000011001074

REMOVAL

1.

Remove A/C unit assembly. Refer to

HA-88, "A/C UNIT ASSEMBLY : Removal and Installation"

.

2.

Disassemble A/C unit assembly, and then remove evaporator assembly.

3.

Remove mounting bolts, and then remove expansion valve from evaporator assembly.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

JMIIA3386ZZ

: Pawl

JMIIA3387ZZ

JMIIA3388ZZ