содержание .. 1268 1269 1270 1271 ..

Nissan X-Trail 32. Manual - part 1270

FAX-72

< REMOVAL AND INSTALLATION >

[4WD]

FRONT WHEEL HUB AND KNUCKLE

REMOVAL AND INSTALLATION

FRONT WHEEL HUB AND KNUCKLE

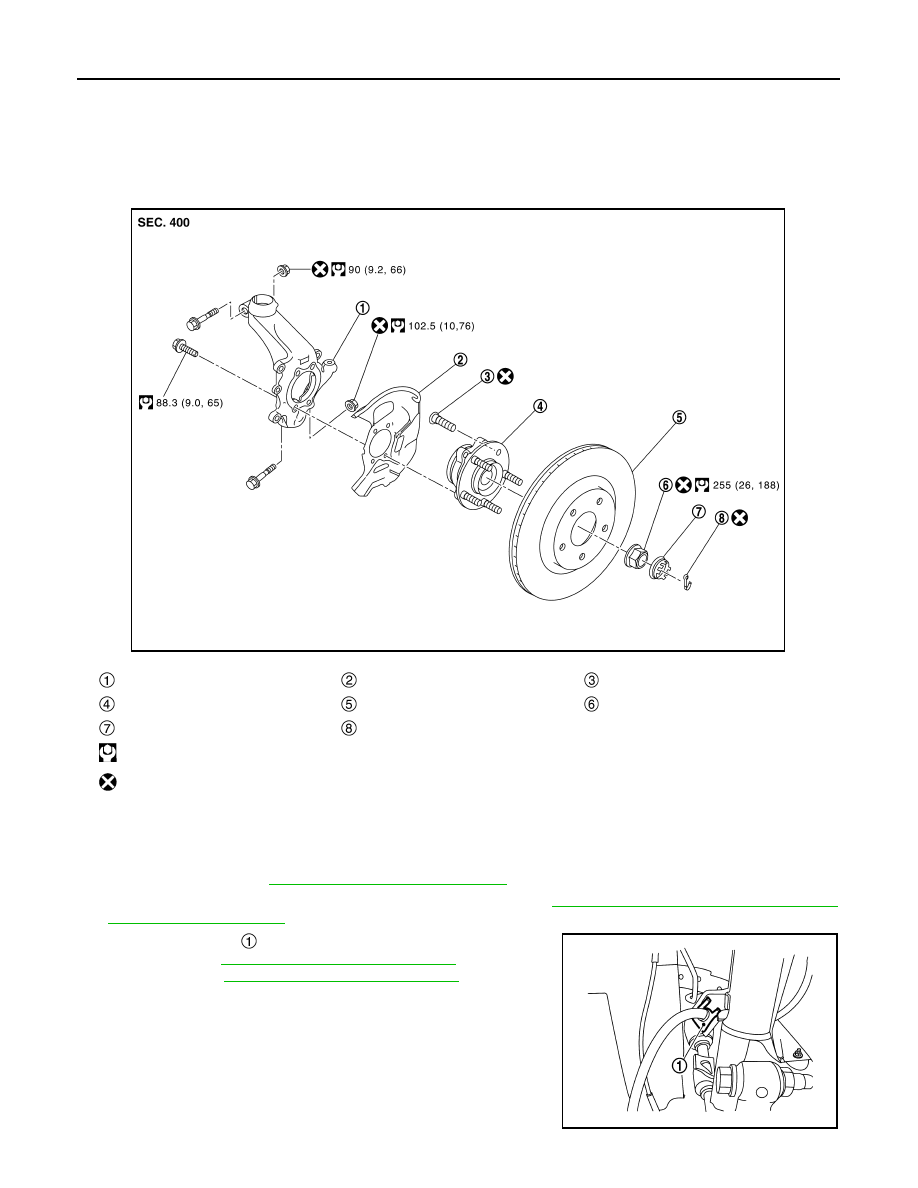

Exploded View

INFOID:0000000010824407

Removal and Installation

INFOID:0000000010824408

REMOVAL

1.

Remove tires. Refer to

WT-61, "Removal and Installation"

.

2.

Remove front wheel sensor from steering kunckle. Refer to

BRC-212, "FRONT WHEEL SENSOR :

.

3.

Remove lock plate

from strut assembly.

• LHD: Refer to

BR-24, "FRONT : Exploded View"

.

• RHD: Refer to

BR-88, "FRONT : Exploded View"

Steering knuckle

Splash guard

Hub bolt

Wheel hub and bearing assembly

Disc rotor

Wheel hub lock nut

Adjusting cap

Cotter pin

: N·m (kg-m, ft-lb)

: Always replace after every disassembly.

JMDIA1520GB

JSDIA3795ZZ