содержание .. 1260 1261 1262 1263 ..

Nissan X-Trail 32. Manual - part 1262

FAX-40

< REMOVAL AND INSTALLATION >

[2WD]

FRONT DRIVE SHAFT

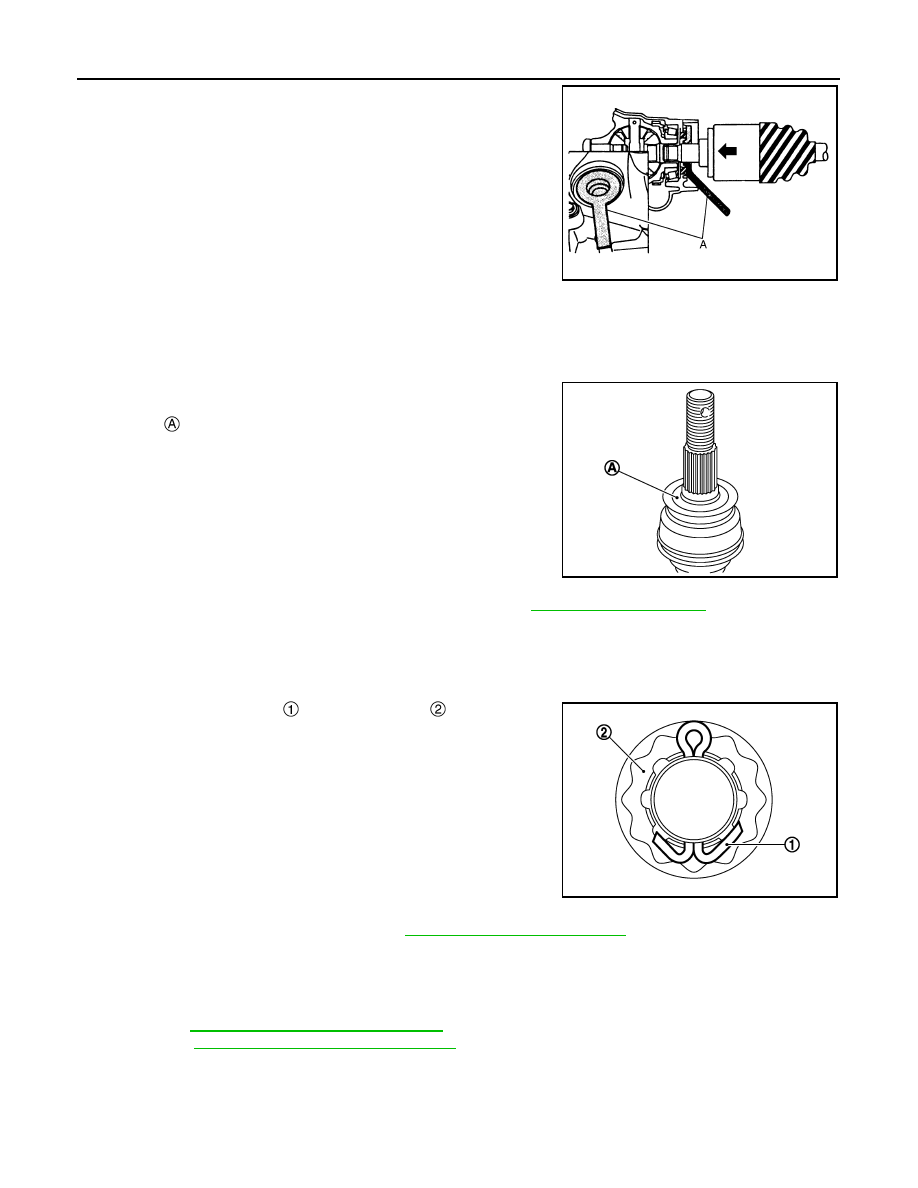

• Place the protector (A) (SST: KV38107900) onto transaxle assem-

bly to prevent damage to the differential side oil seal while inserting

drive shaft. Slide drive shaft sliding joint and tap with a hammer to

install securely.

CAUTION:

• Check that circular clip is completely engaged.

• Never reuse differential side oil seal.

• Clean the matching surface of wheel hub lock nut and wheel hub and bearing assembly.

CAUTION:

Never apply lubricating oil to these matching surface.

• Clean the matching surface of drive shaft and wheel hub and bear-

ing assembly. And then apply paste [service parts (440037S000)]

to surface

of joint sub-assembly of drive shaft.

CAUTION:

Apply paste to cover entire flat surface of joint sub-assembly

of drive shaft.

• Tighten the wheel hub lock nut to the specified torque. Refer to

CAUTION:

• Since the drive shaft is assembled by press-fitting, use the tightening torque range for the wheel

hub lock nut.

• Be sure to use torque wrench to tighten the wheel hub lock nut. Never use a power tool.

• Never reuse wheel hub lock nut.

• When installing a cotter pin

and adjusting cap

, securely bend

the basal portion to prevent rattles.

CAUTION:

Never reuse cotter pin.

• Perform inspection after installation. Refer to

.

Right Side

Note the following, and install in the reverse order of removal.

CAUTION:

Always replace differential side oil seal with new one when installing drive shaft.

• M/T: Refer to

TM-38, "Removal and Installation"

.

• CVT: Refer to

TM-429, "Removal and Installation"

.

JPDIF0023ZZ

Amount paste

: 1.0 – 3.0 g (0.04 – 0.10 oz)

JPDIG0122ZZ

JPDIF0295ZZ