содержание .. 1089 1090 1091 1092 ..

Nissan X-Trail 32. Manual - part 1091

CYLINDER BLOCK

EM-261

< UNIT DISASSEMBLY AND ASSEMBLY >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

• If it exceeds the limit, replace piston and piston pin assembly and/or cylinder block. Refer to

Re-boring Cylinder Bore

1.

Cylinder bore size is determined by adding piston to cylinder bore clearance to piston skirt diameter.

2.

Install lower cylinder block, and tighten mounting bolts to the specified torque. Otherwise, cylinder bores

may be distorted in final assembly. Refer to

EM-248, "Disassembly and Assembly"

for the tightening pro-

cedure.

3.

Cut cylinder bores.

NOTE:

• When any cylinder needs boring, all other cylinders must also be bored.

• Do not cut too much out of cylinder bore at a time. Cut only 0.05 mm (0.0020 in) or so in diameter at a

time.

4.

Hone cylinders to obtain the specified piston to cylinder bore clearance.

5.

Measure the finished cylinder bore for out-of-round and taper.

NOTE:

Measurement should be done after cylinder bore cools down.

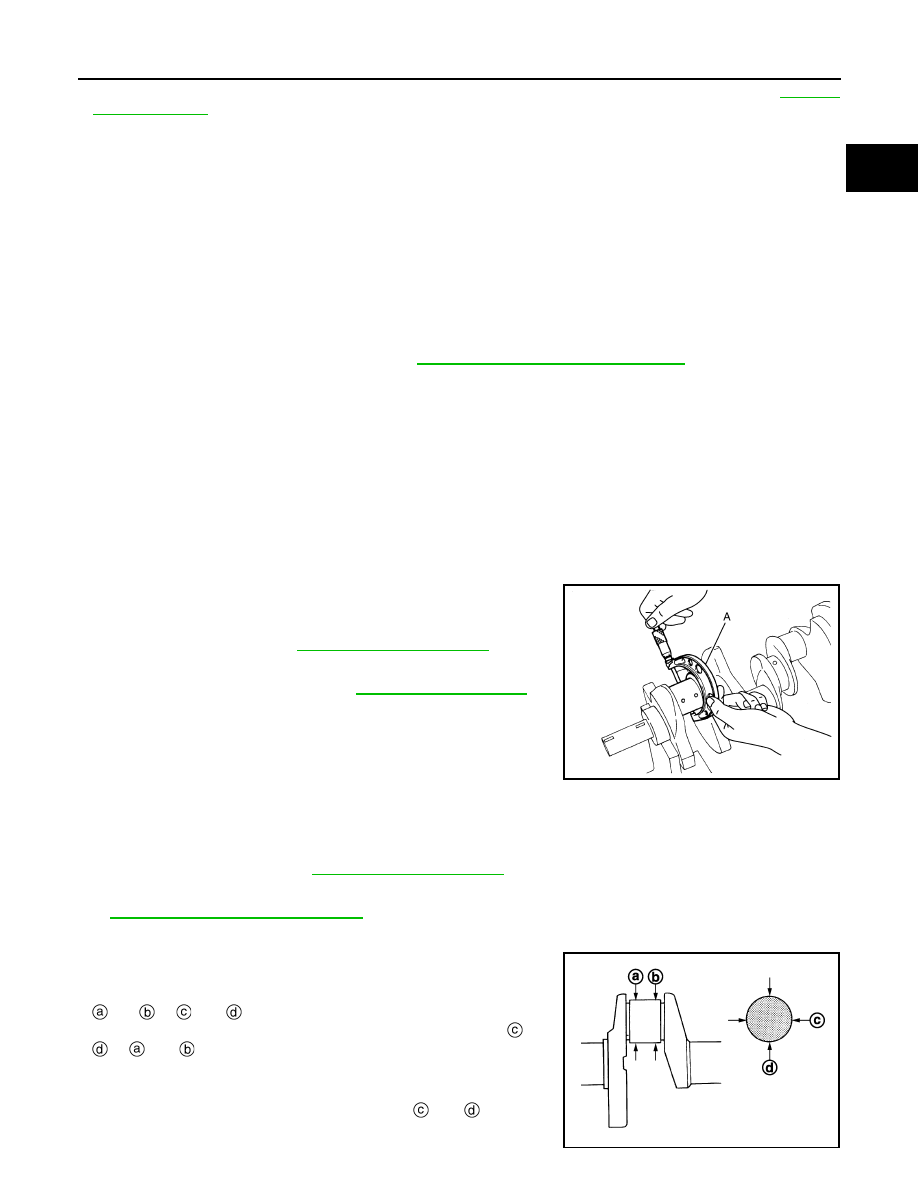

CRANKSHAFT MAIN JOURNAL DIAMETER

• Measure the outer diameter of crankshaft main journals with a

micrometer (A).

• If out of the standard, measure the main bearing oil clearance.

Then use undersize bearing. Refer to

.

CRANKSHAFT PIN JOURNAL DIAMETER

• Measure the outer diameter of crankshaft pin journal with a micrometer.

• If out of the standard, measure the connecting rod bearing oil clearance. Then use undersize bearing. Refer

EM-284, "Connecting Rod Bearing"

.

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

• Measure the dimensions at four different points as shown in the

figure on each main journal and pin journal with a micrometer.

• Out-of-round is indicated by the difference in dimensions between

and

at

and .

• Taper is indicated by the difference in dimension between

and

at

and

.

Re-bored size calculation: D = A + B - C

where,

A: Piston diameter as measured

B: Piston - to - cylinder bore clearance (standard value)

C: Honing allowance 0.02 mm (0.0008 in)

D: Bored diameter

Standard :

.

JPBIA0228ZZ

Standard

: Refer to

Limit:

Out-of-round [Difference

between

and

]

JPBIA0229ZZ