содержание .. 1082 1083 1084 1085 ..

Nissan X-Trail 32. Manual - part 1084

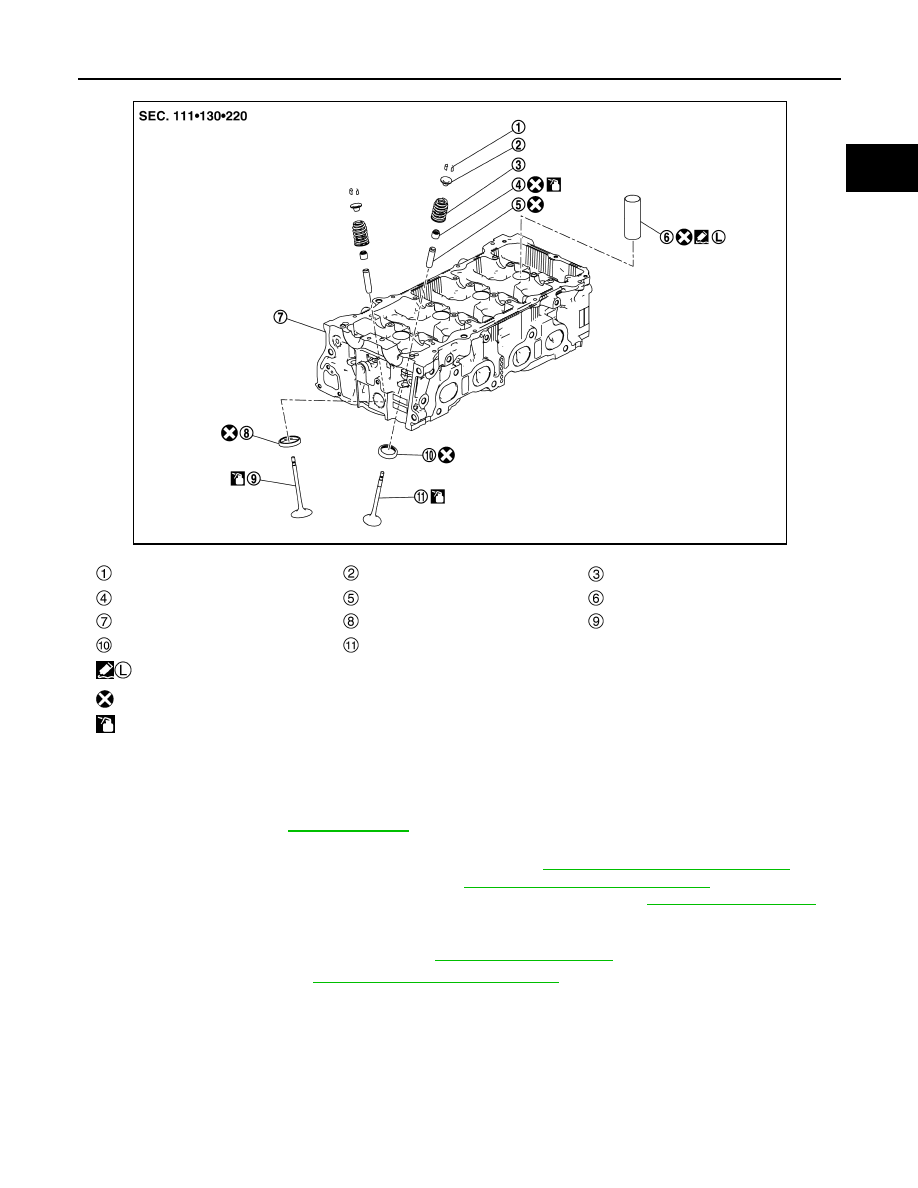

CYLINDER HEAD

EM-233

< UNIT DISASSEMBLY AND ASSEMBLY >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Removal and Installation

INFOID:0000000010783816

REMOVAL

1.

Drain engine oil. Refer to

.

2.

Remove the following components and related parts.

• Exhaust manifold and three way catalyst assembly: Refer to

EM-180, "Removal and Installation"

• Intake manifold and fuel tube assembly: Refer to

EM-176, "Removal and Installation"

.

• Water control valve and water control valve housing (water outlet): Refer to

.

NOTE:

Can be removed and installed even when assembled with cylinder head.

3.

Remove front cover and timing chain. Refer to

4.

Remove camshafts. Refer to

EM-222, "Removal and Installation"

.

5.

Securely support bottom of cylinder block with a jack or equivalent tool, and release the hoist that was

supporting it.

Valve collet

Valve spring retainer

Valve spring (with valve spring seat)

Valve oil seal

Valve guide

Spark plug tube

Cylinder head

Valve seat (INT)

Valve (INT)

Valve seat (EXH)

Valve (EXH)

: Apply thread locking sealant.

: Always replace after every disassembly.

: Should be lubricated with oil.

JSBIA3389ZZ