содержание .. 1040 1041 1042 1043 ..

Nissan X-Trail 32. Manual - part 1042

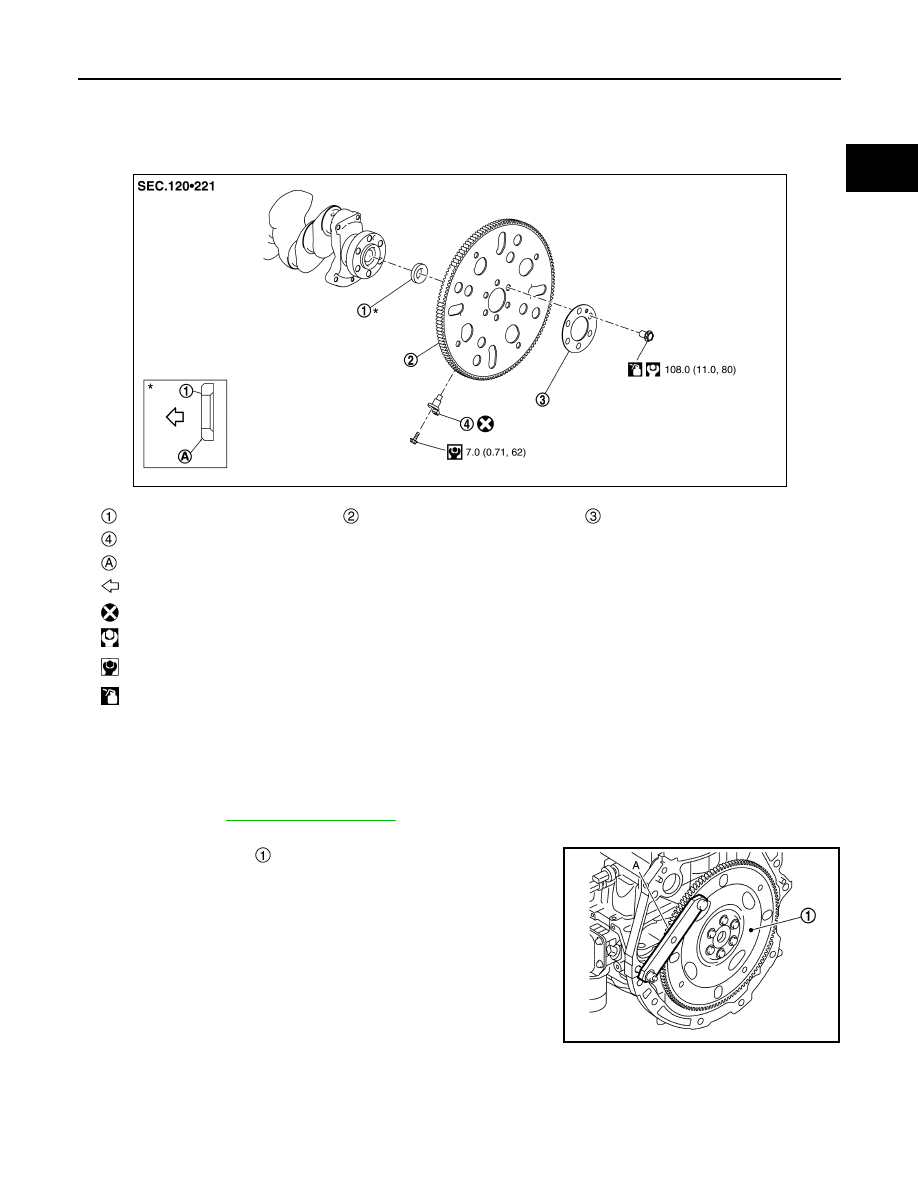

DRIVE PLATE

EM-65

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

DRIVE PLATE

Exploded View

INFOID:0000000010783713

Removal and Installation

INFOID:0000000010783714

REMOVAL

1.

Remove the engine and the transaxle assembly from the vehicle, and separate the transaxle from the

engine. Refer to

2.

Remove drive plate.

• Secure drive plate

with a stopper plate [SST: KV11105210]

(A), and remove mounting bolts.

• Using TORX socket (size E20), loosen mounting bolts.

• loosen mounting bolts in diagonal order.

CAUTION:

• Never disassemble them.

Pilot converter

Drive plate

Reinforcement plate

Crankshaft position sensor 2

Chamfered

: Crankshaft side

: Always replace after every disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: Should be lubricated with oil.

JPBIA6837GB

JPBIA4425ZZ