содержание .. 1018 1019 1020 1021 ..

Nissan X-Trail 32. Manual - part 1020

BRAKE SWITCH

EC-1209

< DTC/CIRCUIT DIAGNOSIS >

[R9M]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

2.

Disconnect brake pedal position switch harness connector.

3.

Check the continuity between brake pedal position switch terminals as per the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 2.

2.

CHECK BRAKE PEDAL POSITION SWITCH-2

1.

Adjust brake pedal position switch installation. Refer to

BR-11, "Inspection and Adjustment"

(LHD models)

BR-75, "Inspection and Adjustment"

(RHD models).

2.

Check the continuity between brake pedal position switch terminals as per the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace brake pedal position switch.

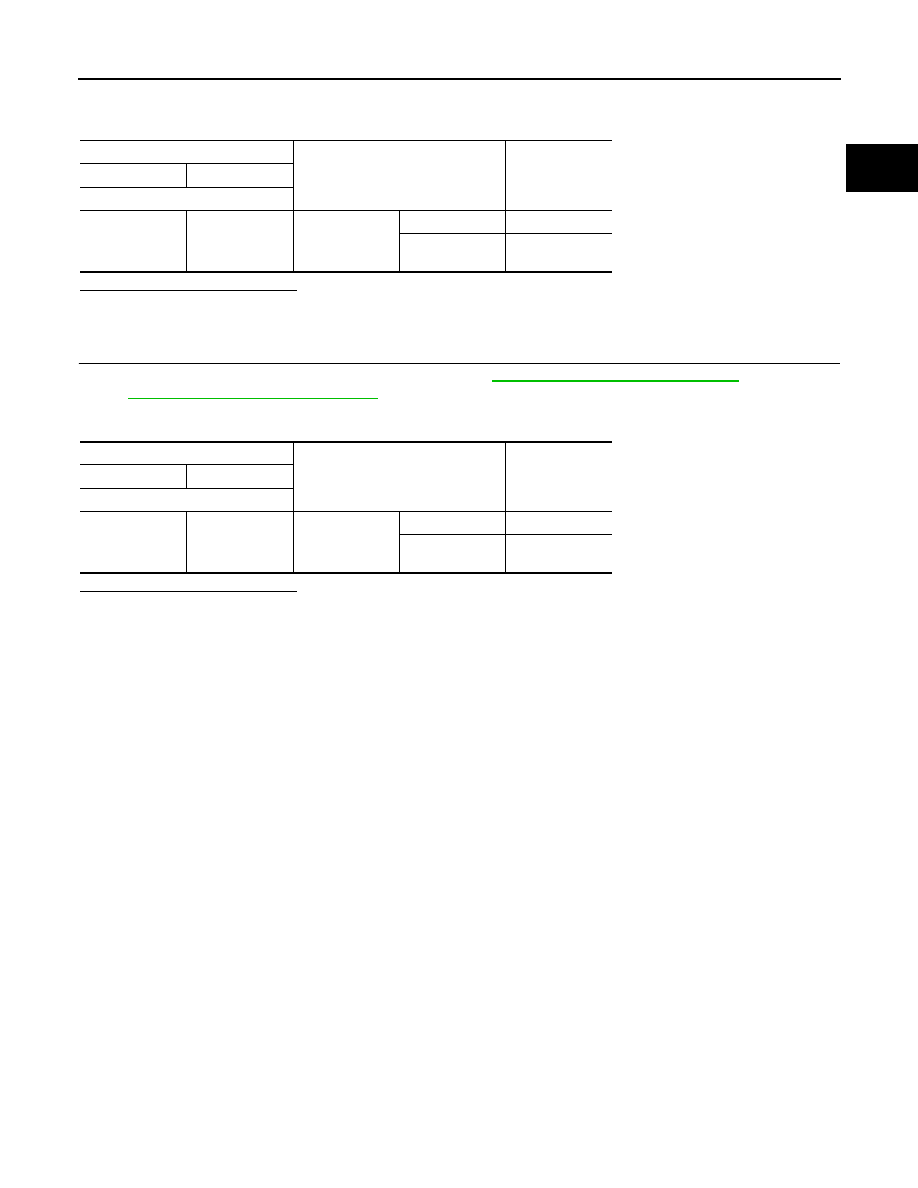

Brake pedal position switch

Condition

Continuity

+

-

Terminals

1

2

Brake pedal

Fully released

Existed

Slightly de-

pressed

Not existed

Brake pedal position switch

Condition

Continuity

+

-

Terminals

1

2

Brake pedal

Fully released

Existed

Slightly de-

pressed

Not existed