Qashqai J11. Door & Lock - part 40

REAR DOOR LOCK

DLK-641

< REMOVAL AND INSTALLATION >

[TYPE 4]

C

D

E

F

G

H

I

J

L

M

A

B

DLK

N

O

P

8.

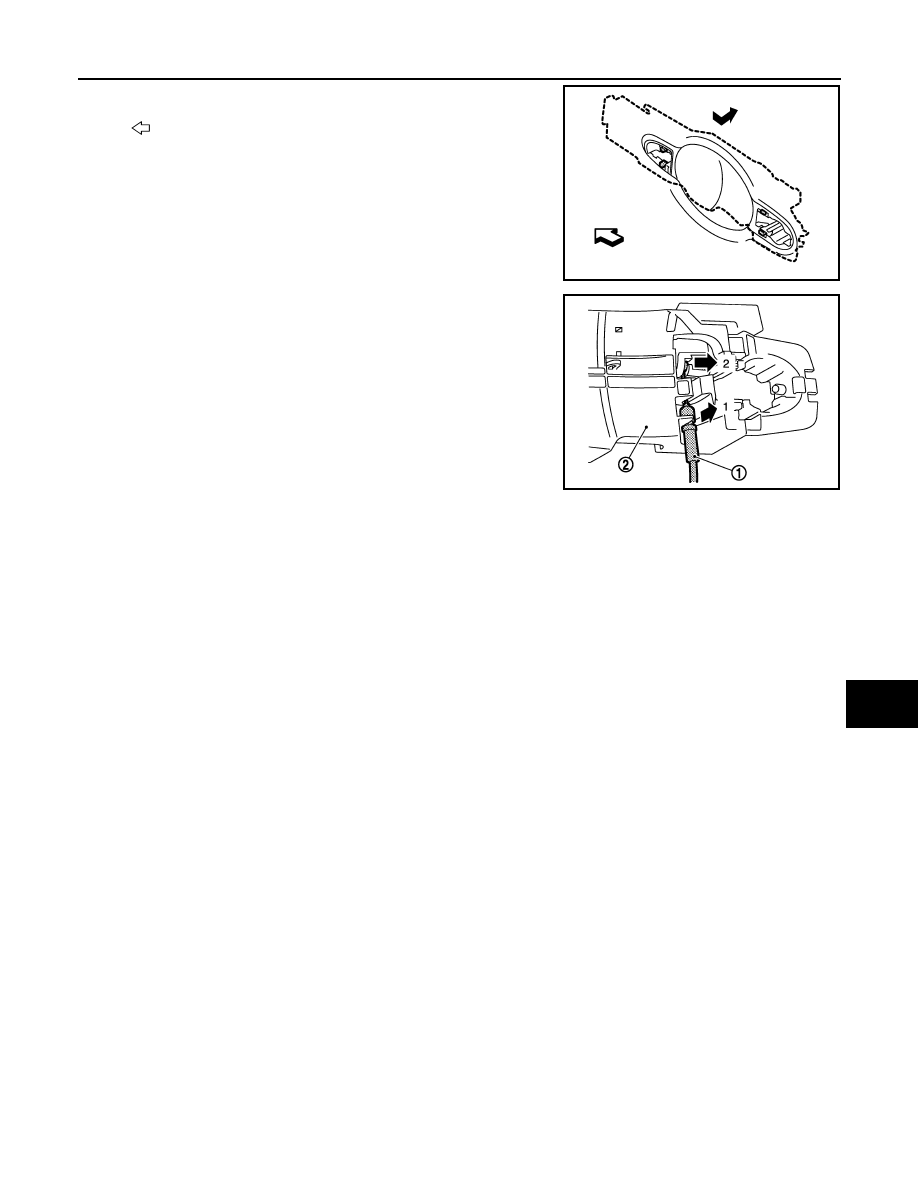

Slide outside handle bracket toward rear of vehicle to remove.

9.

Disconnect outside handle cable (1) from outside handle bracket

(2) according to the numerical order 1

→

2 indicated by arrows as

shown in the figure.

CAUTION:

Never bend the outside handle cable end.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

• Check that door lock cables are normally engaged with inside handle and outside handle.

• After installation, check door open/close, and lock/unlock operation.

: Vehicle front

JMKIA5890ZZ

JMKIA5891ZZ