Qashqai J11. Maintenance - part 7

MA-98

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE (R9M)

ENGINE MAINTENANCE (R9M)

DRIVE BELT

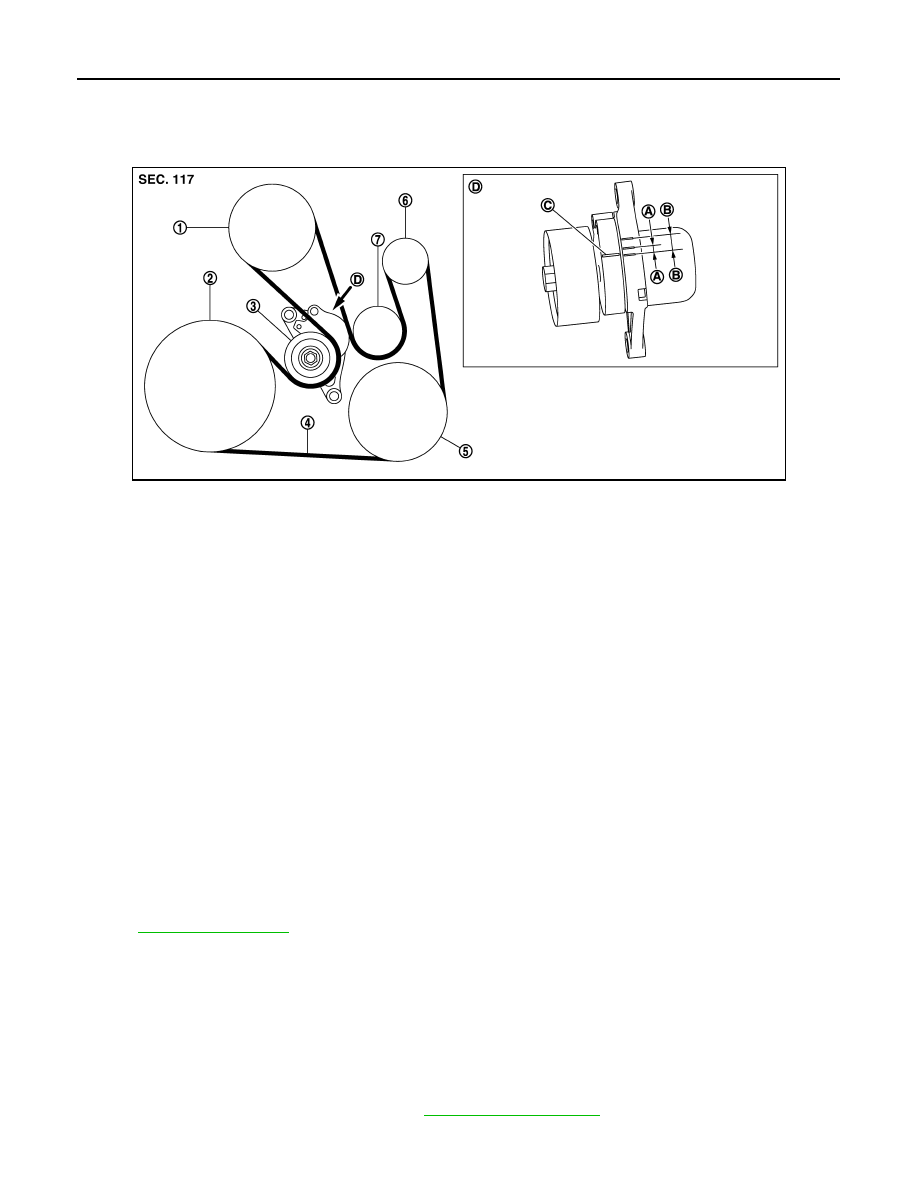

DRIVE BELT : Exploded View

INFOID:0000000010503160

DRIVE BELT : Checking

INFOID:0000000010503161

WARNING:

Be sure to perform this step when the engine is stopped.

• Check that the indicator (C) (notch on fixed side) of drive belt auto-tensioner is within the possible use range

(B).

NOTE:

• Check the drive belt auto-tensioner indication when the engine is cold.

• When new drive belt is installed, the indicator (notch on fixed side) should be within the range (A) in the fig-

ure.

• Visually check entire drive belt for wear, damage or cracks.

• If the indicator (notch on fixed side) is out of the possible use range or belt is damaged, replace drive belt.

CAUTION:

Drive belt auto-tensioner and idler pulley must be replaced with new ones when the drive belt is

replaced.

DRIVE BELT : Tension Adjustment

INFOID:0000000010503162

DRIVE BELT : Removal and Installation

INFOID:0000000010503163

CAUTION:

• Replace the drive belt that has been removed with a new one.

• Drive belt auto-tensioner and idler pulley must be replaced with new ones when the drive belt is

replaced.

• Never run the engine without the drive belt to avoid damaging the crankshaft pulley.

REMOVAL

1.

Remove front fender protector (RH). Refer to

E1BIA1197GB

1.

Water pump

2.

Crankshaft pulley

3.

Drive belt auto-tensioner

4.

Drive belt

5.

A/C compressor or Idler roller

6.

Alternator

7.

Idler pulley

A.

Range when new drive belt is installed

B.

Possible use range

C.

Indicator

D.

View