Qashqai J11. General information - part 2

ABBREVIATIONS

GI-15

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

M

B

GI

N

O

P

E

F

G

H

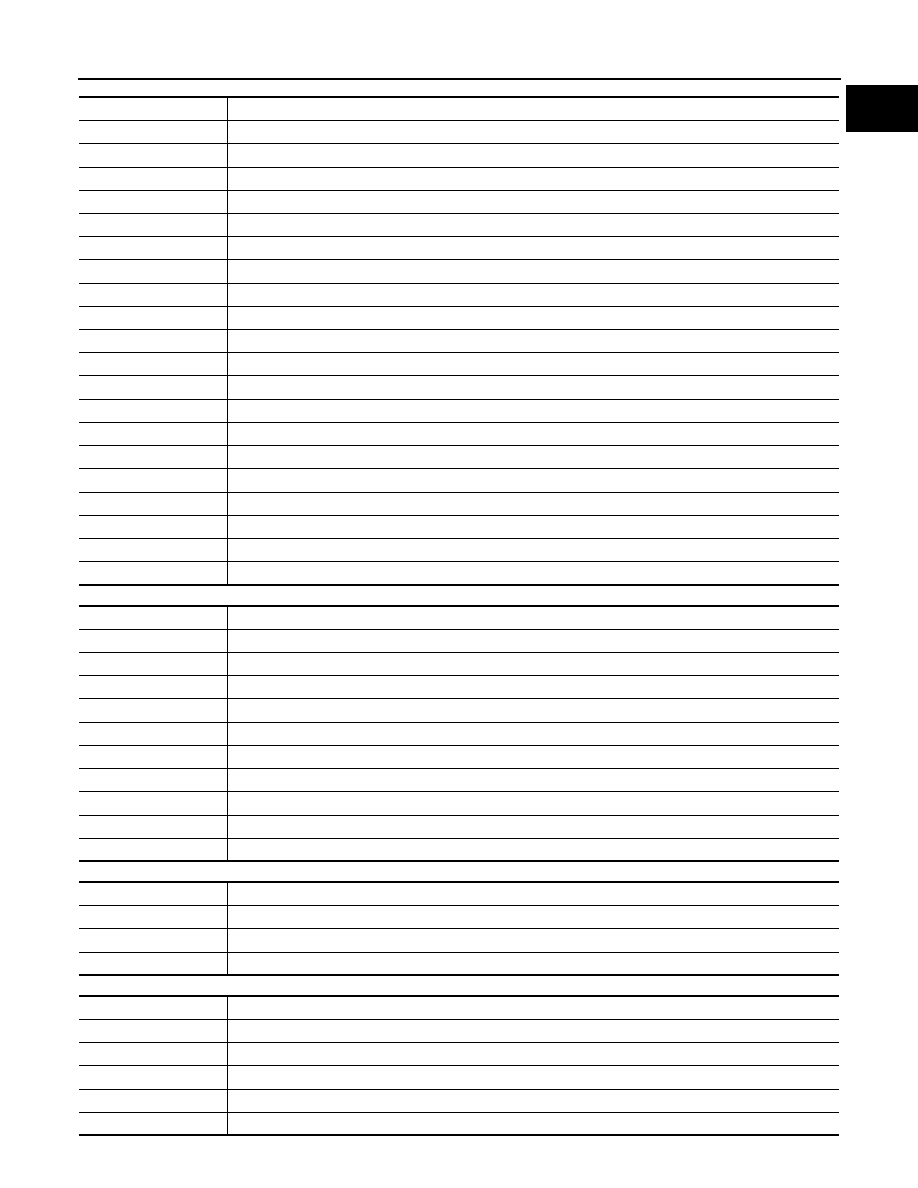

ABBREVIATION

DESCRIPTION

E/T

Exhaust temperature

EBD

Electric brake force distribution

EC

Engine control

ECL

Engine coolant level

ECM

Engine control module

ECT

Engine coolant temperature

ECV

Electrical control valve

EEPROM

Electrically erasable programmable read only memory

EFT

Engine fuel temperature

EGR

Exhaust gas recirculation

EGRT

Exhaust gas recirculation temperature

EGT

Exhaust gas temperature

EOP

Engine oil pressure

EP

Exhaust pressure

EPR

Exhaust pressure regulator

EPS

Electronically controlled power steering

ESP

Electronic stability program system

EVAP canister

Evaporative emission canister

EVSE

Electric vehicle supply equipment

EXC

Exhaust control

ABBREVIATION

DESCRIPTION

FC

Fan control

FCW

Forward collision warning

FEB

Forward emergency braking

FIC

Fuel injector control

FP

Fuel pump

FR

Front

FRP

Fuel rail pressure

FRT

Fuel rail temperature

FTP

Fuel tank pressure

FTT

Fuel tank temperature

ABBREVIATION

DESCRIPTION

GND

Ground

GPS

Global positioning system

GST

Generic scan tool

ABBREVIATION

DESCRIPTION

HBMC

Hydraulic body-motion control system

HDD

Hard disk drive

HO2S

Heated oxygen sensor

HOC

Heated oxidation catalyst

HPCM

Hybrid power train control module