Qashqai J11. Body repair - part 20

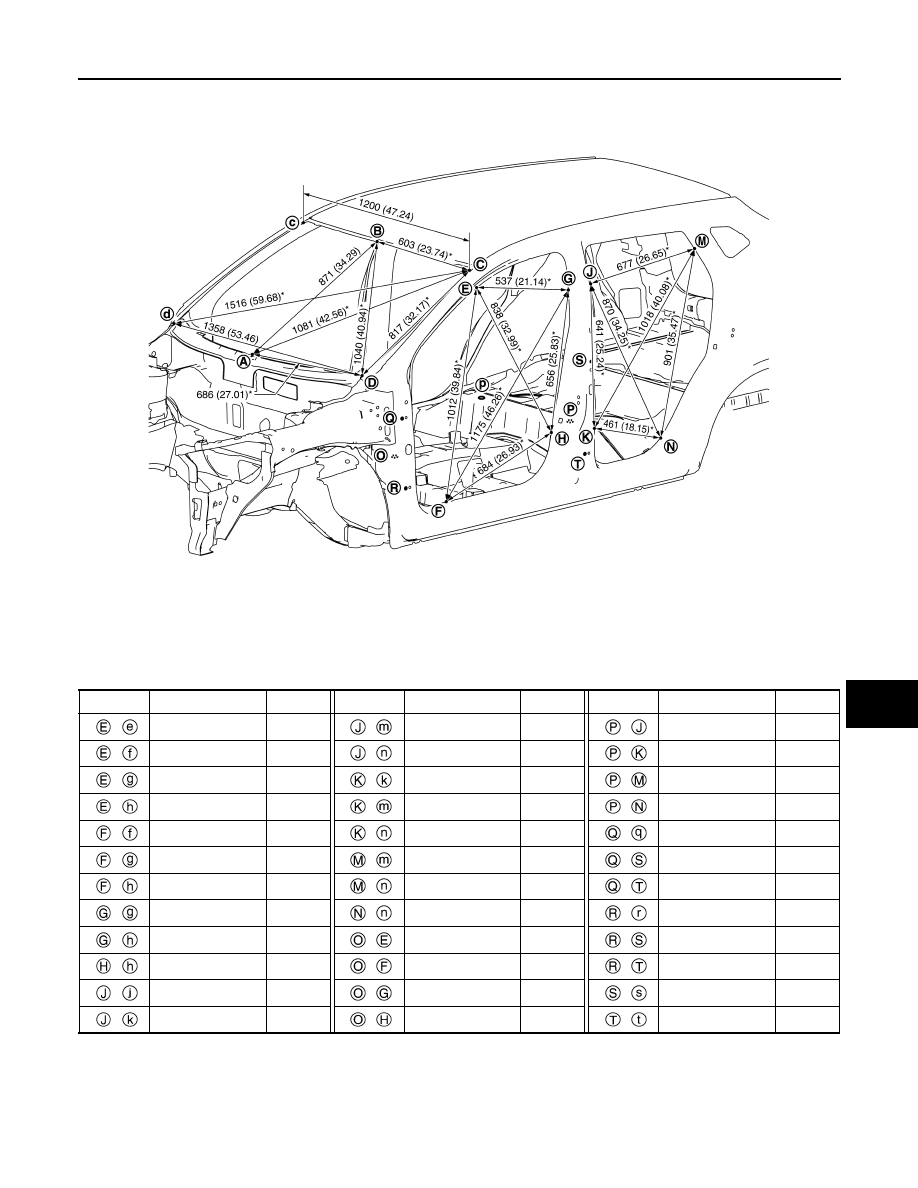

BODY ALIGNMENT

BRM-305

< SERVICE DATA AND SPECIFICATIONS (SDS)

[FOR RUSSIA]

C

D

E

F

G

H

I

J

L

M

A

B

BRM

N

O

P

«The others»

Unit: mm (in)

MEASUREMENT POINTS

Unit: mm (in)

JSKIA3911GB

Point

Dimension

Memo

Point

Dimension

Memo

Point

Dimension

Memo

-

1280 (50.39)

-

1486 (58.50)*

-

850 (33.46)*

-

1701 (66.97)*

-

1660 (65.35)*

-

493 (19.41)*

-

1431 (56.34)*

-

1462 (57.56)

-

1013 (39.88)*

-

1604 (63.15)*

-

1705 (67.13)*

-

480 (18.90)*

-

1462 (57.56)

-

1533 (60.35)*

-

1609 (63.35)

-

1841 (72.48)*

-

1279 (50.35)

-

1152 (45.35)*

-

1614 (63.54)*

-

1637 (64.45)*

-

1157 (45.55)*

-

1374 (54.09)

-

1461 (57.52)

-

1636 (64.41)

-

1562 (61.50)*

-

1139 (44.84)*

-

1215 (47.83)*

-

1461 (57.52)

-

790 (31.10)*

-

1094 (43.07)*

-

1369 (53.90)

-

1190 (46.85)*

-

1618 (63.70)

-

1553 (61.14)*

-

833 (32.80)*

-

1633 (64.29)