Qashqai J11. Glass & Window System - part 2

SIDE WINDOW GLASS

GW-17

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

L

M

A

B

GW

N

O

P

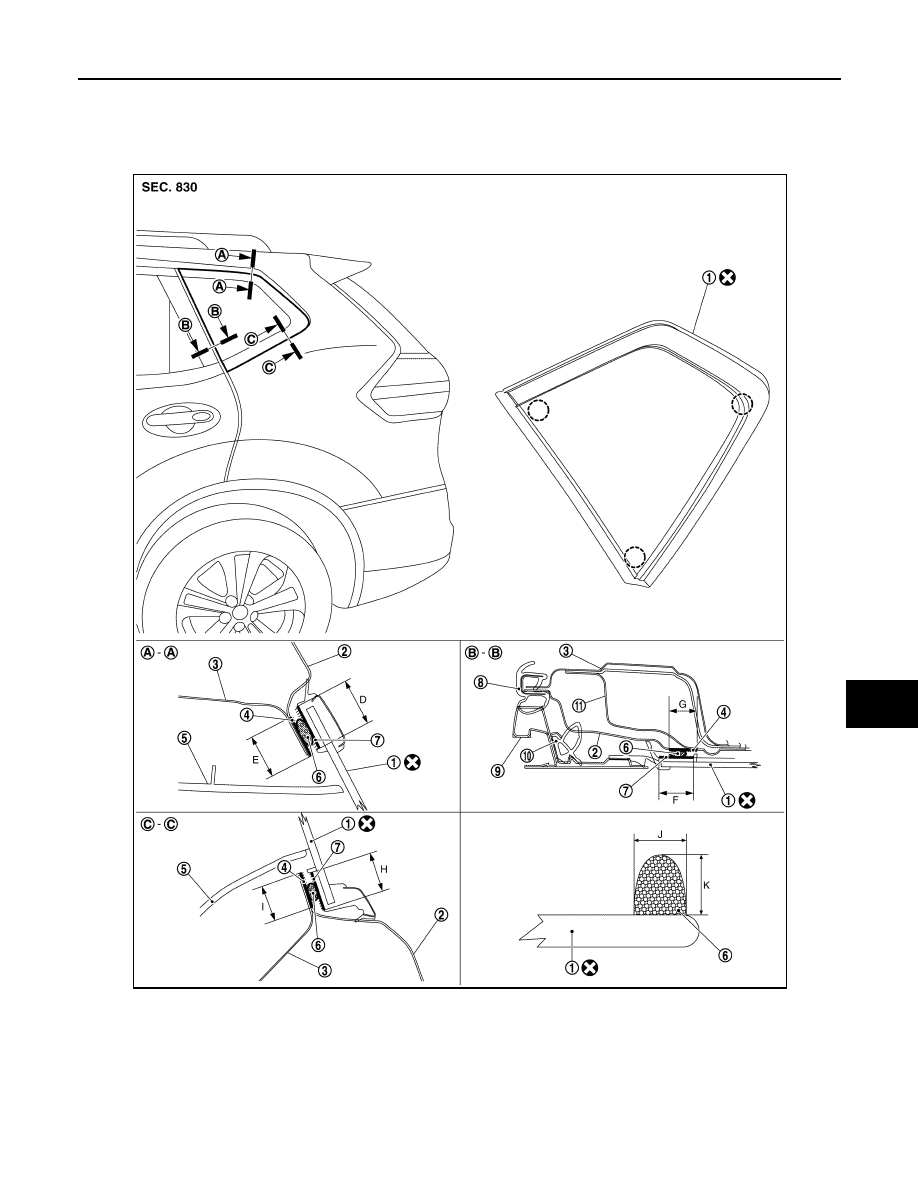

SIDE WINDOW GLASS

Exploded View

INFOID:0000000010478437

1.

Side window glass

2.

Body side outer panel

3.

Rear pillar inner panel

4.

Painted surface for primer

5.

Luggage side upper finisher

6.

Sealant

7.

Glass for primer

8.

Rear body side welt

9.

Rear door sash

10.

11.

Rear pillar inner reinforcement D.

17 mm (0.67 in)

E.

16 mm (0.63 in)

F.

17 mm (0.67 in)

G.

16 mm (0.63 in)

H.

17 mm (0.67 in)

I.

16 mm (0.63 in)

J.

7 mm (0.28 in)

JMKIB3124ZZ