Qashqai J11. Engine mechanical (HRA2DDT, K9K, MR20DD) - part 26

VACUUM PUMP

EM-401

< REMOVAL AND INSTALLATION >

[R9M]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

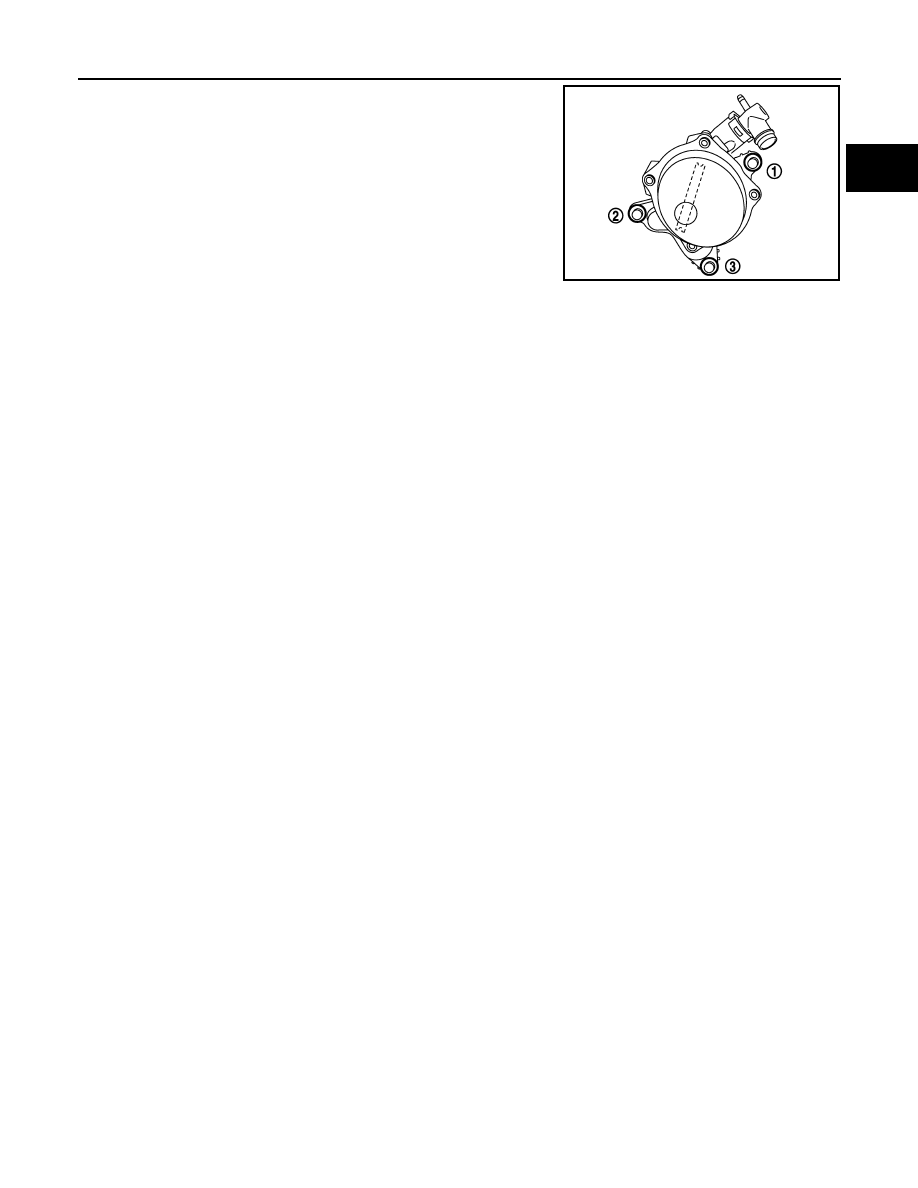

• Tighten mounting bolts in numerical order as shown in the figure.

CAUTION:

Be sure to check that the vacuum pump is in contact with the

cylinder head before tightening the mounting bolts.

E1BIA0614ZZ