Qashqai J11. Engine mechanical (HRA2DDT, K9K, MR20DD) - part 12

ENGINE STAND SETTING

EM-177

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

UNIT DISASSEMBLY AND ASSEMBLY

ENGINE STAND SETTING

Setting

INFOID:0000000010715492

NOTE:

Explained here is how to disassemble with engine stand supporting transaxle surface. When using different

type of engine stand, note with difference in steps and etc.

1.

Remove the engine and the transaxle assembly from the vehicle, and separate the transaxle from the

engine. Refer to

(CVT models).

2.

Install engine to engine stand with the following procedure:

a.

Remove flywheel or drive plate. Refer to

.

b.

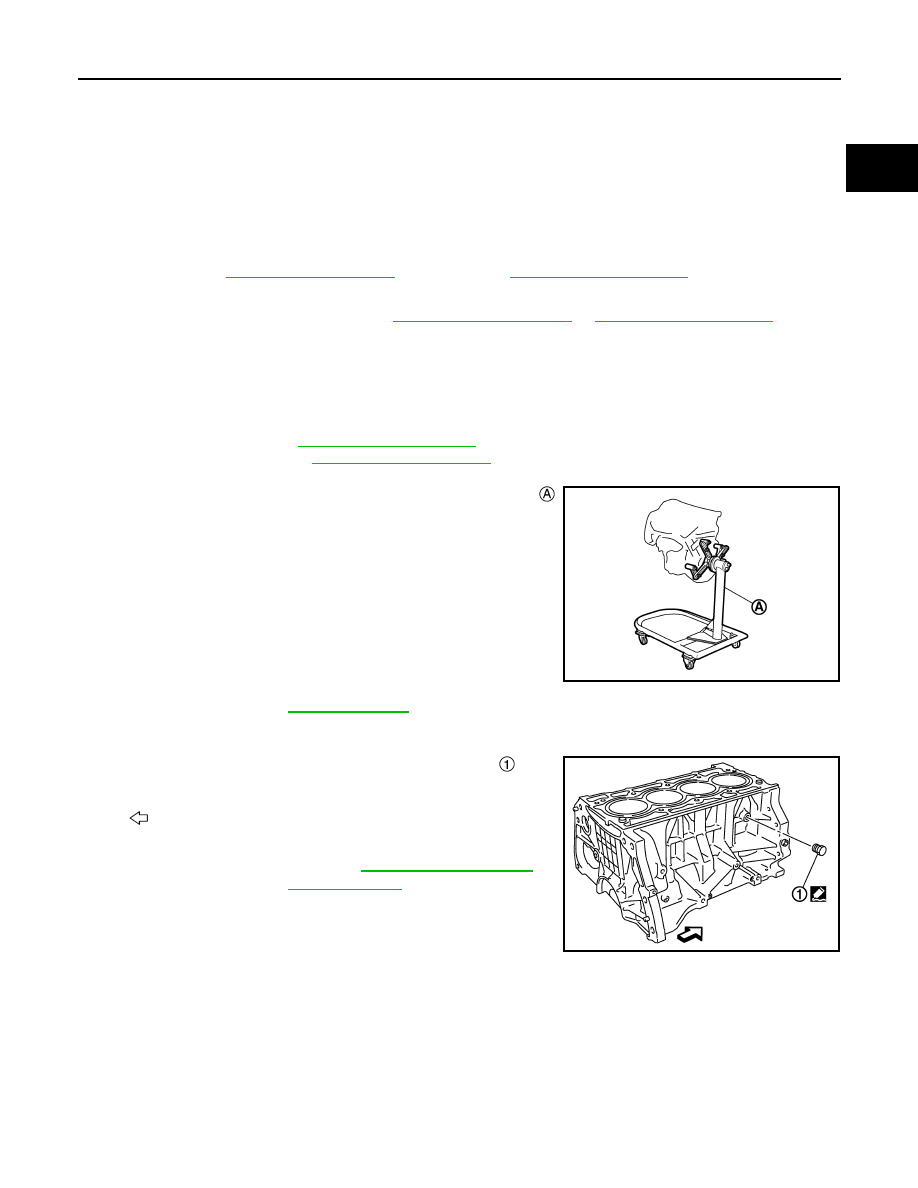

Lift the engine with a hoist to install it onto widely use engine stand.

CAUTION:

• Use the engine stand that has a load capacity [approximately 135 kg (298 lb) or more] large

enough for supporting the engine weight.

• If the load capacity of stand is not adequate, remove the following parts beforehand to reduce the poten-

tial risk of overturning stand.

- Intake manifold: Refer to

.

- Exhaust manifold: Refer to

NOTE:

The figure shows an example of widely used engine stand

that can support mating surface of transaxle with drive plate

removed.

CAUTION:

Before removing the hanging chains, check the engine

stand is stable and there is no risk of overturning.

3.

Drain engine oil. Refer to

.

CAUTION:

Be sure to clean drain plug and install with new drain plug washer.

4.

Drain engine coolant by removing water drain plug

from

inside of the engine.

Use Genuine Liquid Gasket (Three Bond 1217H) or equiva-

lent.

PBIC3227J

: Engine front

Tightening torque

: Refer to

PBIC3228J