Qashqai J11. Engine mechanical (HRA2DDT, K9K, MR20DD) - part 11

HIGH PRESSURE FUEL PUMP AND FUEL HOSE

EM-161

< REMOVAL AND INSTALLATION >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

7.

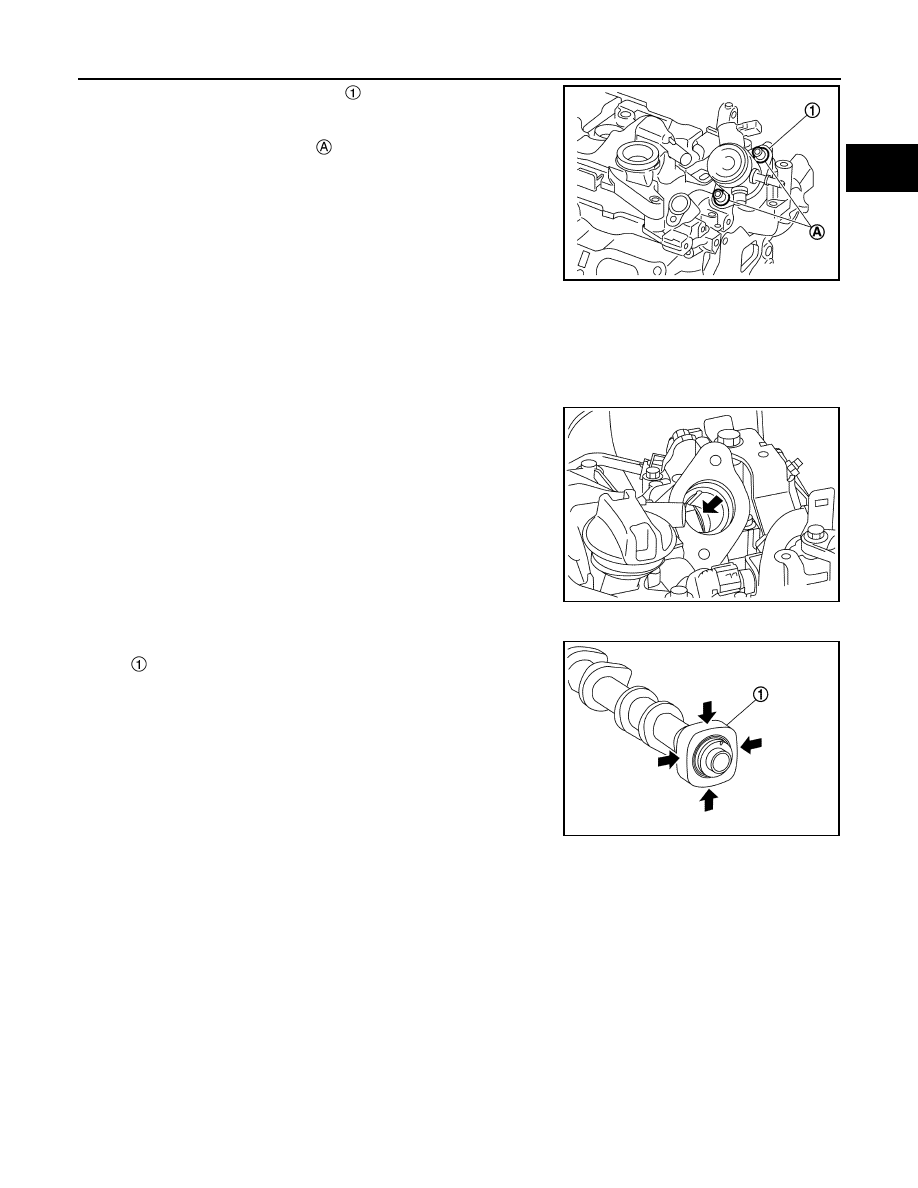

Remove high pressure fuel pump

and lifter.

CAUTION:

To prevent damage to high pressure fuel pump and cam-

shaft bracket, loosen bolt

alternately by one turn at a

time until the reaction force applied on the high pressure

fuel pump disappears.

INSTALLATION

CAUTION:

• Do not reuse O-rings.

• To prevent damage to parts due to generated abnormal stress and eccentric load, always observe

the installation procedure.

1.

Install high pressure fuel pump according to the following procedure.

a.

Check the orientation of pump cam from the mounting area

(view arrow) of high pressure fuel pump.

b.

Aim pump cam at the BDC area (arrow position).

NOTE:

For BDC area, anywhere within the area indicated by arrow can

be accepted.

c.

Install O-ring to high pressure fuel pump. When handing new O-ring, paying attention to the following cau-

tion items:

CAUTION:

• Do not reuse O-ring.

• Handle O-ring with bare hands. Never wear gloves.

• Lubricate O-ring with new engine oil.

• Never clean O-ring with solvent.

• Check that O-ring and its mating part are free of foreign material.

• Never damage O-ring with tools and fingernails during the installation. In addition, twisting or

stretching O-ring is not allowed. If O-ring is stretched during the installation to high pressure

fuel pump, never install high pressure fuel pump immediately.

d.

Install high pressure fuel pump lifter.

e.

Apply oil to the fitting area of high pressure fuel pump O-ring and camshaft bracket side to install high

pressure fuel pump.

f.

Install high pressure fuel pump. To prevent damage to high pressure fuel pump and camshaft bracket, the

following instructions must be observed.

JSBIA1673ZZ

JPBIA4379ZZ

: Camshaft (EXH)

JPBIA4380ZZ