Qashqai J11. Engine mechanical (HRA2DDT, K9K, MR20DD) - part 4

IGNITION COIL, SPARK PLUG AND ROCKER COVER

EM-49

< REMOVAL AND INSTALLATION >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

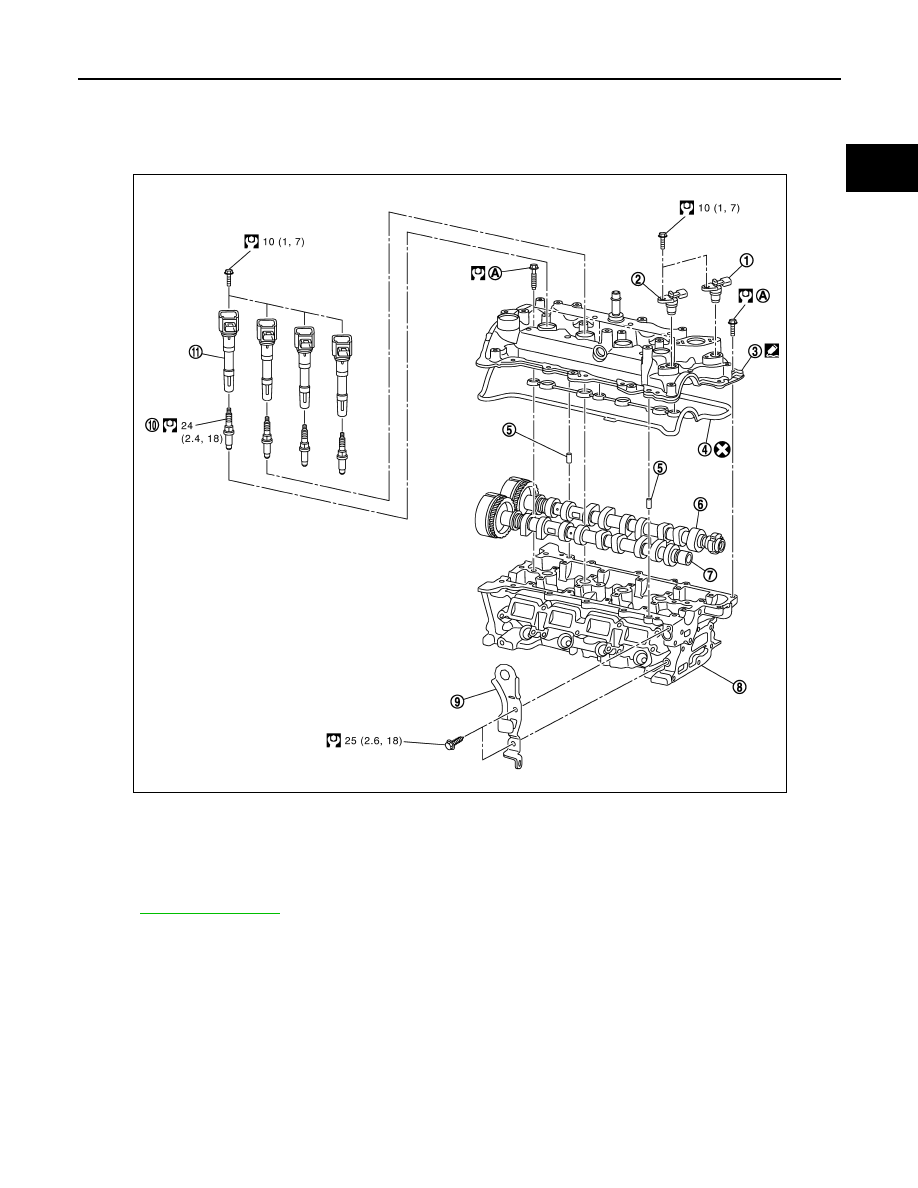

IGNITION COIL, SPARK PLUG AND ROCKER COVER

Exploded View

INFOID:0000000010282226

for symbol marks in the figure.

Removal and Installation

INFOID:0000000010282227

REMOVAL

1.

Camshaft position sensor (EXH)

2.

Camshaft position sensor (INT)

3.

Rocker cover

4.

Rocker cover gasket

5.

Dowel pin

6.

Camshaft (EXH)

7.

Camshaft (INT)

8.

Cylinder head

9.

Engine slinger

10.

Spark plug

11.

Ignition coil

E1BIA1014GB