Qashqai J11. Engine mechanical (HRA2DDT, K9K, MR20DD) - part 2

DRIVE BELT

EM-17

< PERIODIC MAINTENANCE >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

2.

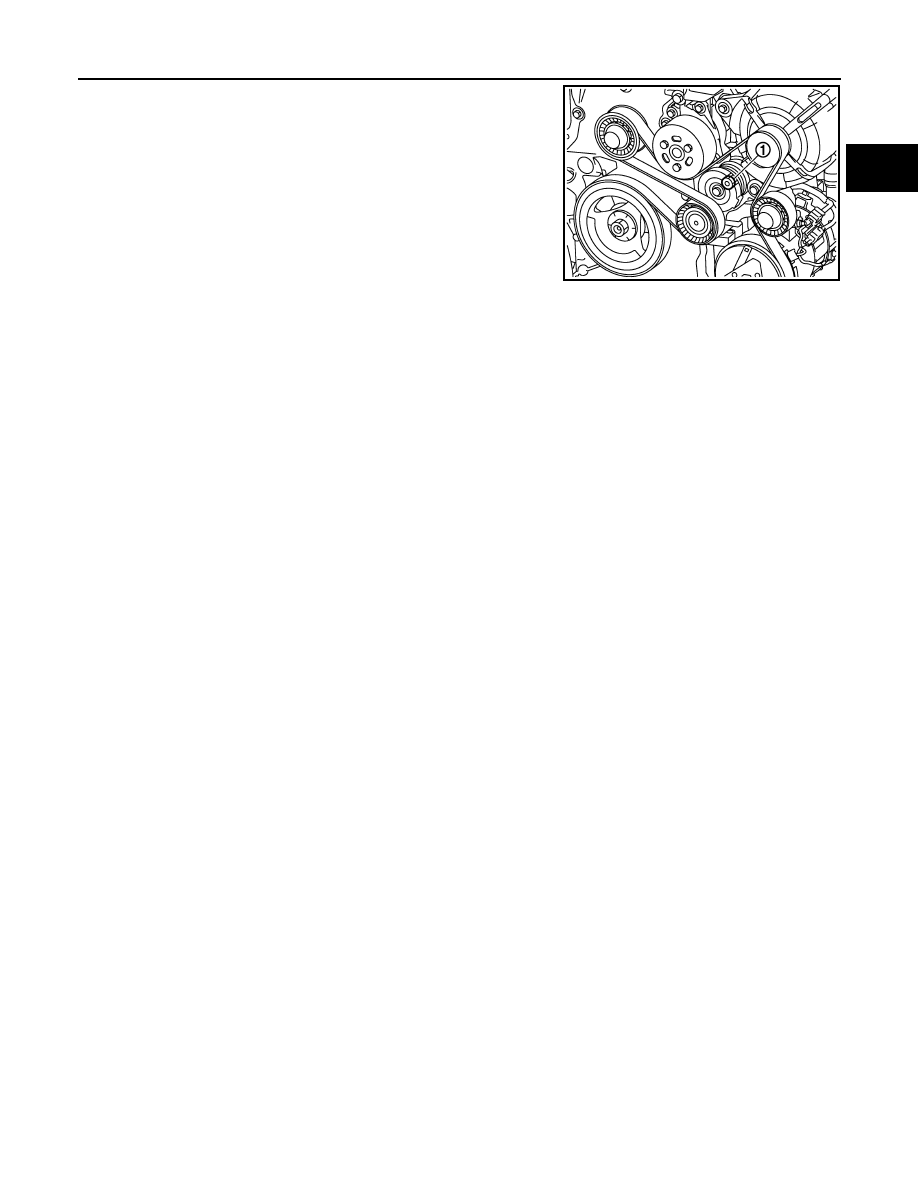

Release the tension on the drive belt by turning drive belt auto-

tensioner (1) clockwise using a 16mm (0.63 in) socket and hold

drive belt auto-tensioner to this position.

3.

Remove drive belt.

4.

Release the drive belt auto-tensioner until normal position.

CAUTION:

• Clean with a brush the v-block of the crankshaft pulley to remove all dust.

INSTALLATION

1.

Rotate drive belt auto-tensioner clockwise using a 16mm (0.63 in) socket and hold it.

2.

Install drive belt.

CAUTION:

• Check that drive belt is completely set to pulleys.

• Check for engine oil, working fluid and engine coolant are not adhered to drive belt and each pulley

groove.

3.

Release the drive belt auto-tensioner until drive belt tension is apply.

4.

Turn crankshaft clockwise twice to set drive belt tension on all pulleys.

5.

Install in the reverse order of removal.

E1BIA1000ZZ