Qashqai J11. Engine control system (MR20DD) - part 22

ECM-338

< DTC/CIRCUIT DIAGNOSIS >

[MR20DD]

P1574 ASCD VEHICLE SPEED SENSOR

P1574 ASCD VEHICLE SPEED SENSOR

DTC Description

INFOID:0000000010703029

The ECM receives two vehicle speed sensor signals via CAN communication line. One is sent from combina-

tion meter, and the other is from CVT C/U. The ECM uses these signals for ASCD control. Refer to

"AUTOMATIC SPEED CONTROL DEVICE (ASCD) : System Description"

for ASCD functions.

DTC DETECTION LOGIC

POSSIBLE CAUSE

• Harness or connectors (CAN communication line is open or shorted.)

• Combination meter

• Wheel sensor

• ABS actuator and electric unit (control unit)

• ECM

• TCM

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.

CHECK DTC PRIORITY

If DTC P1574 is displayed with DTC U1001, P0500, P0605 or P0607, first perform the trouble diagnosis for

DTC U1001, P0500, P0605 or P0607.

Is applicable DTC detected?

YES

>> Perform diagnosis of applicable. Refer to

NO

>> GO TO 2.

2.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1.

Turn ignition switch OFF and wait at least 10 seconds.

2.

Turn ignition switch ON.

3.

Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 3.

3.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Start engine.

2.

Drive the vehicle at more than 40 km/h (25 MPH).

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

This procedure may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a

road test is expected to be easier, it is unnecessary to lift the vehicle.

3.

Check DTC.

Is DTC detected?

YES

>> Proceed to

ECM-339, "Diagnosis Procedure"

.

NO-1

>> To check malfunction symptom before repair: Refer to

GI-41, "Intermittent Incident"

.

NO-2

>> Confirmation after repair: INSPECTION END

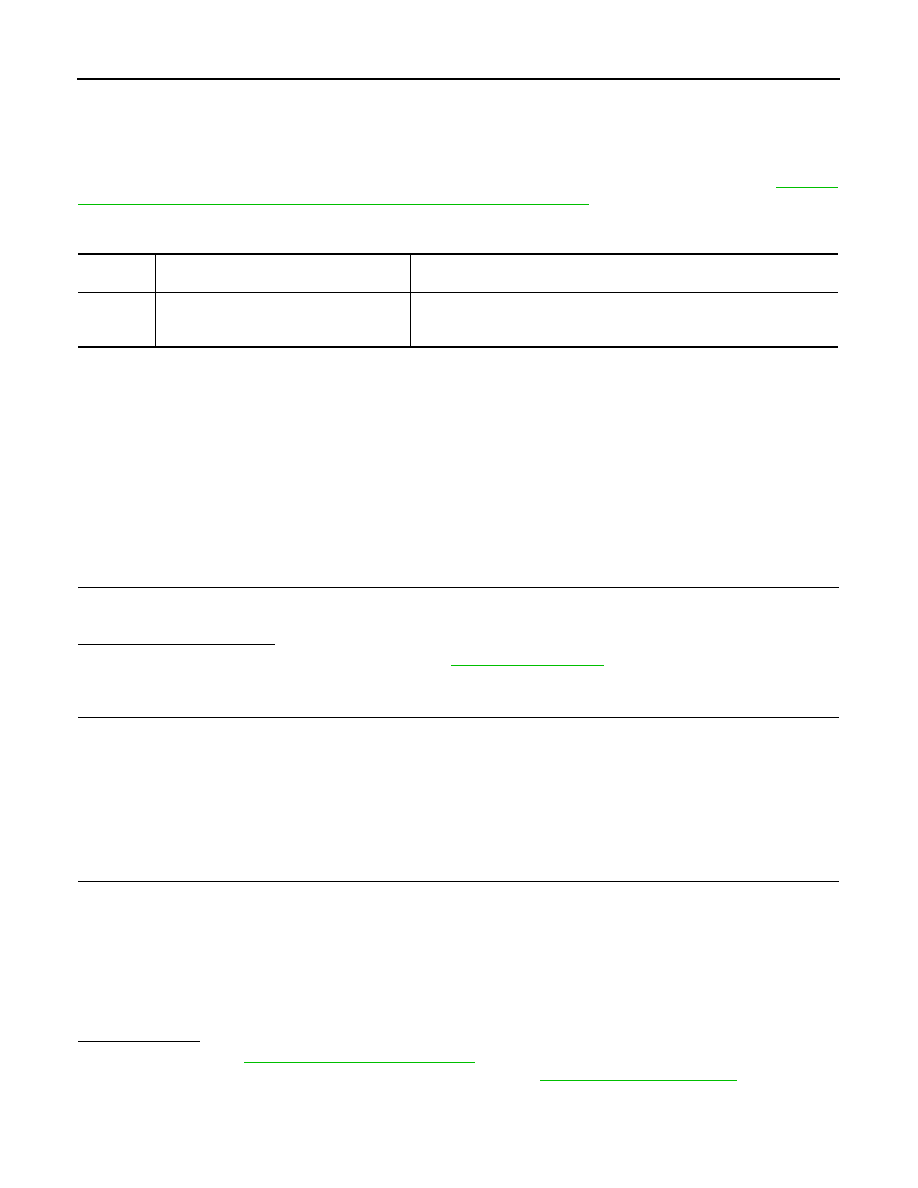

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P1574

ASCD VHL SPD SEN

(ASCD vehicle speed sensor)

ECM detects a difference between two vehicle speed signals is out of the

specified range.