Qashqai J11. Engine control system (K9K) - part 9

DIAGNOSIS AND REPAIR WORKFLOW

ECK-129

< BASIC INSPECTION >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

ECK

N

P

O

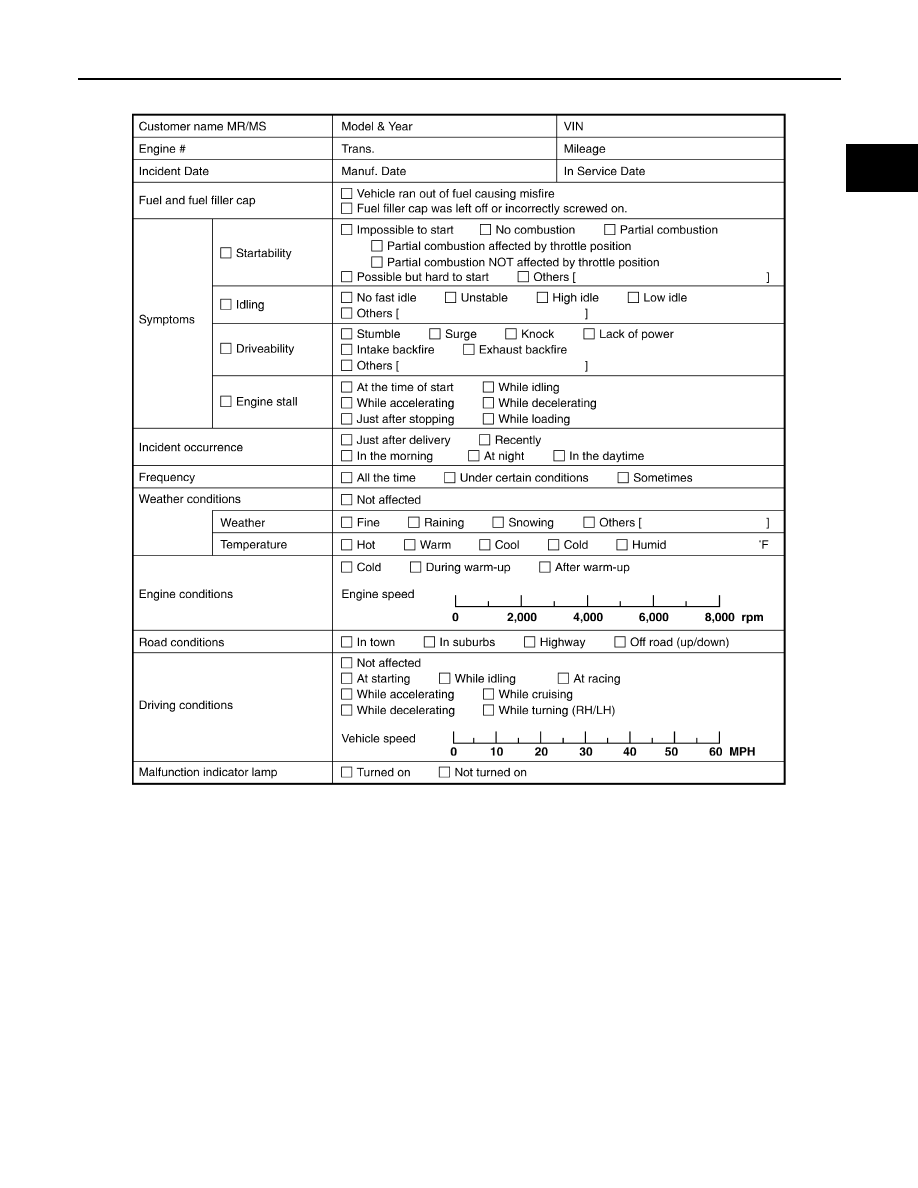

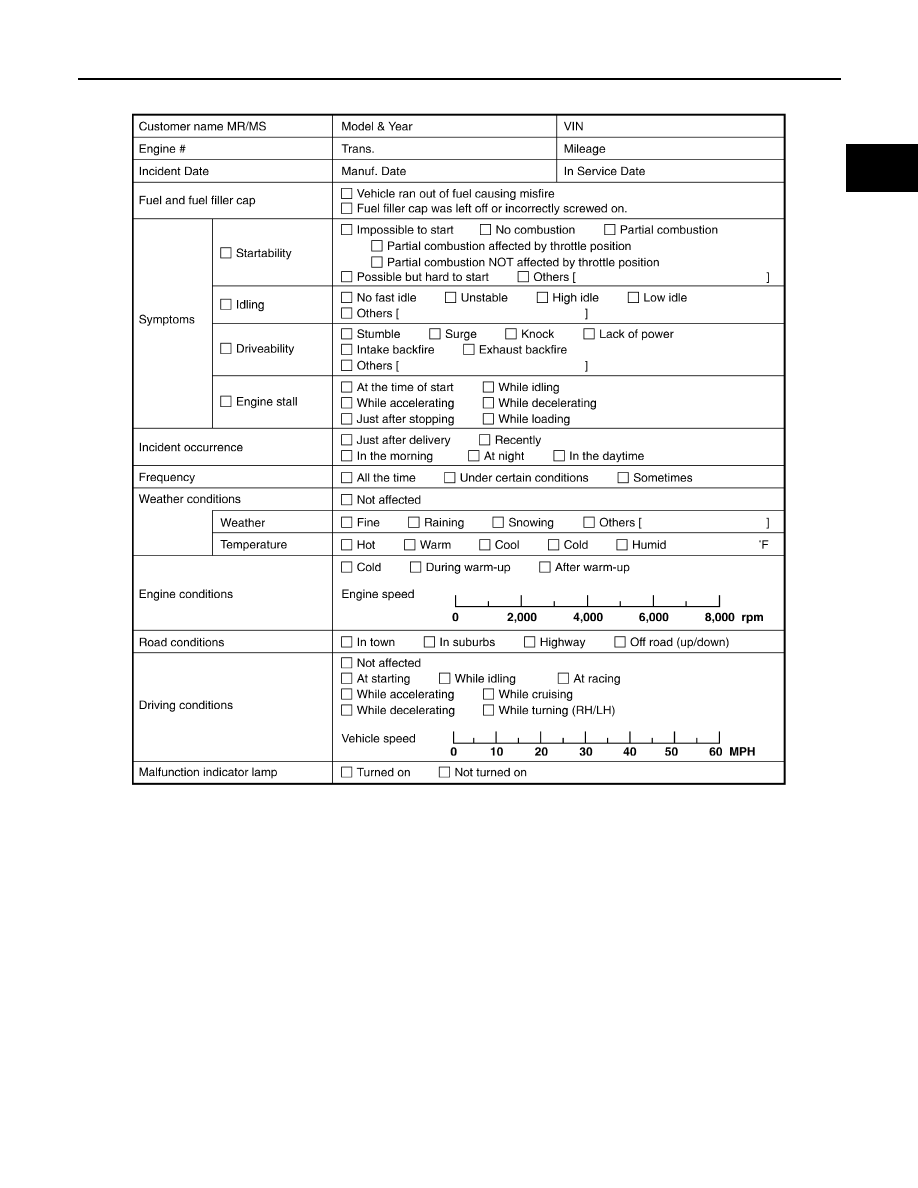

WORKSHEET SAMPLE

MTBL0017

|

|

|

DIAGNOSIS AND REPAIR WORKFLOW ECK-129 < BASIC INSPECTION > [K9K] C D E F G H I J K L M A ECK N P O WORKSHEET SAMPLE MTBL0017 |