Qashqai J11. Brake system - part 6

BR-82

< REMOVAL AND INSTALLATION >

[RHD]

FRONT DISC BRAKE

5.

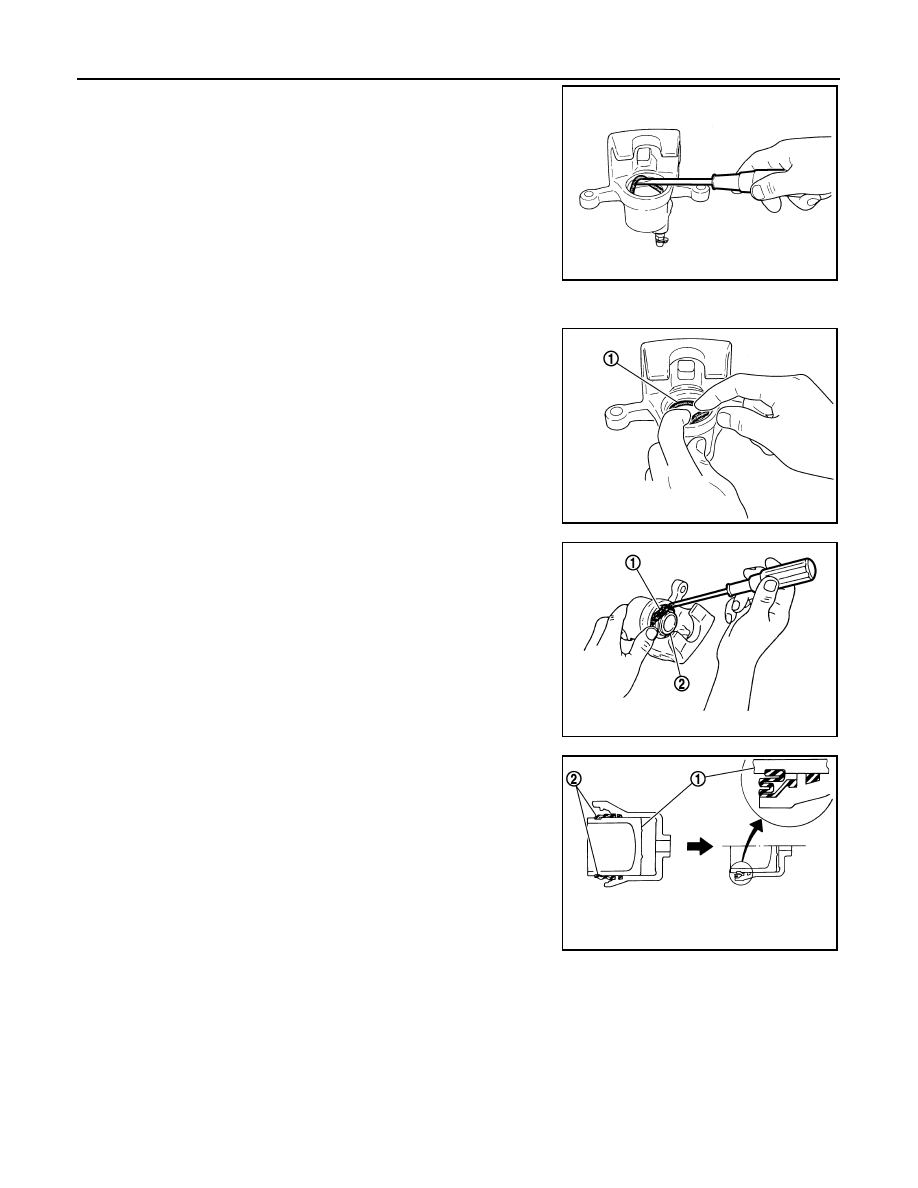

Remove piston seal from cylinder body using suitable tool.

CAUTION:

Be careful not to damage a cylinder inner wall.

ASSEMBLY

1.

Apply rubber grease to piston seal (1), and install to cylinder

body.

CAUTION:

Never reuse piston seal.

2.

Apply rubber grease to piston boot (1). Cover the piston (2) end

with piston boot, and then install cylinder side lip on piston boot

securely into a groove on cylinder body.

CAUTION:

Never reuse piston boot.

3.

Apply brake fluid to piston (1). Push piston into cylinder body by

hand and push piston boot (2) piston-side lip into the piston

groove.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

4.

Apply rubber grease to bushing, install bushing to sliding pin.

5.

Apply rubber grease to sliding pins and sliding pin boots, install

sliding pins and sliding pin boots to torque member.

6.

Install the cylinder body to the torque member and tighten the

sliding pin bolts to the specified torque.

BRAKE CALIPER ASSEMBLY : Inspection and Adjustment

INFOID:0000000010305482

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of the cylinder for rust, wear, cracks or damage. Replace the cylinder if any abnormal

condition is detected.

CAUTION:

Always clean with new brake fluid. Never clean with mineral oil such as gasoline and light oil.

JPFIA0038ZZ

JPFIA0039ZZ

JPFIA0040ZZ

JPFIA0034ZZ