Qashqai J11. Brake system - part 4

BR-50

< PRECAUTION >

[RHD]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000010305431

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake System

INFOID:0000000010305432

WARNING:

Clean any dust from the front brake and rear brake with a vacuum dust collector. Never blow with com-

pressed air.

CAUTION:

• Only use “DOT 4” brake fluid. Refer to

MA-59, "Fluids and Lubricants"

.

• Never reuse drained brake fluid.

• Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

• Always clean with new brake fluid when cleaning the master cylinder, brake caliper and other com-

ponents.

• Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and

cause improper operation.

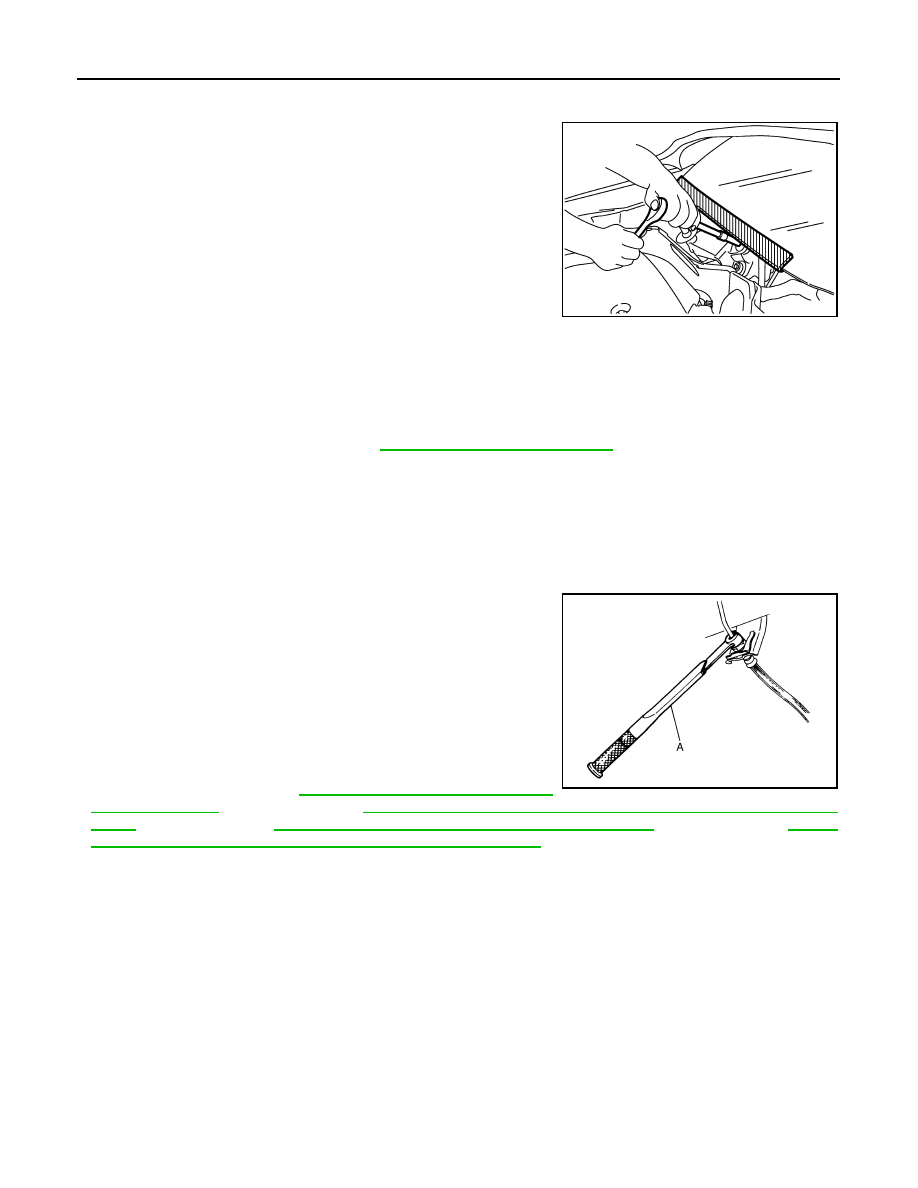

• Always loosen the brake tube flare nut with a flare nut wrench.

• Tighten the brake tube flare nut to the specified torque with

flare nut torque wrench (A).

• Always confirm the specified tightening torque when install-

ing the brake pipes.

• Turn the ignition switch OFF and disconnect the ABS actuator

and electric unit (control unit) connector or the battery nega-

tive terminal before performing the work.

• Check that no brake fluid leakage is present after replacing

the parts.

• Burnish the brake contact surfaces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage. Refer to

BR-79, "BRAKE PAD : Inspection

(front brake pad),

BR-82, "BRAKE CALIPER ASSEMBLY : Inspection and Adjust-

BR-85, "BRAKE PAD : Inspection and Adjustment"

(rear brake pad),

"BRAKE CALIPER ASSEMBLY : Inspection and Adjustment"

(rear disc rotor).

PIIB3706J

JPFIA0061ZZ