Nissan Qashqai J11. Manual - part 904

BR-88

< REMOVAL AND INSTALLATION >

[RHD]

REAR DISC BRAKE

4.

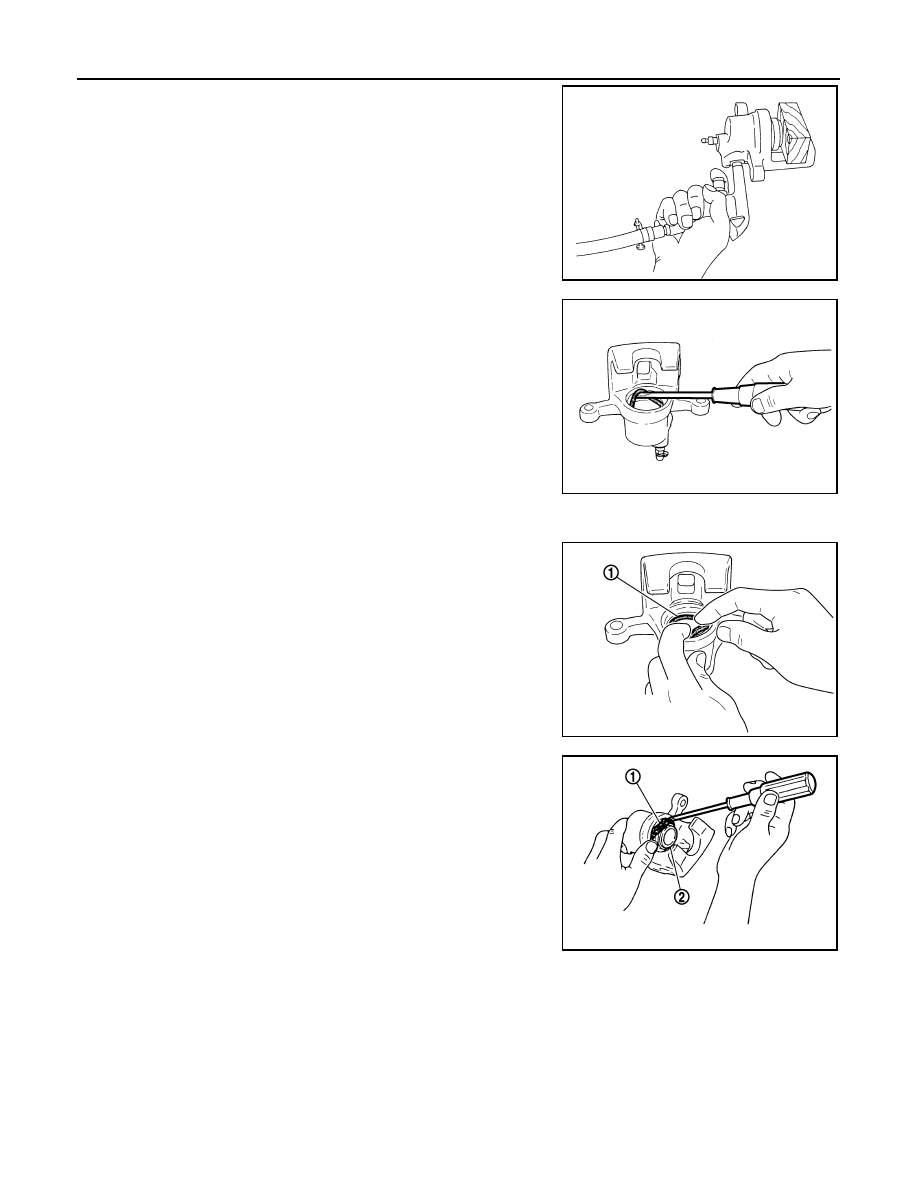

Place a wooden block as shown in the figure, and blow air from

union bolt mounting hole to remove piston and piston boot.

CAUTION:

Never get fingers caught in the piston.

5.

Remove piston seal from cylinder body using suitable tool.

CAUTION:

Be careful not to damage a cylinder inner wall.

ASSEMBLY

1.

Apply polyglycol ether based lubricant to piston seal (1), and

install to cylinder body.

CAUTION:

Never reuse piston seal.

2.

Apply rubber grease to piston boot (1). Cover the piston (2) end

with the piston boot, and then install cylinder side lip on the pis-

ton boot securely into the groove on cylinder body.

CAUTION:

Never reuse piston boot.

BRD0041D

JPFIA0038ZZ

JPFIA0039ZZ

JPFIA0040ZZ