Nissan Qashqai J11. Manual - part 901

BR-76

< REMOVAL AND INSTALLATION >

[RHD]

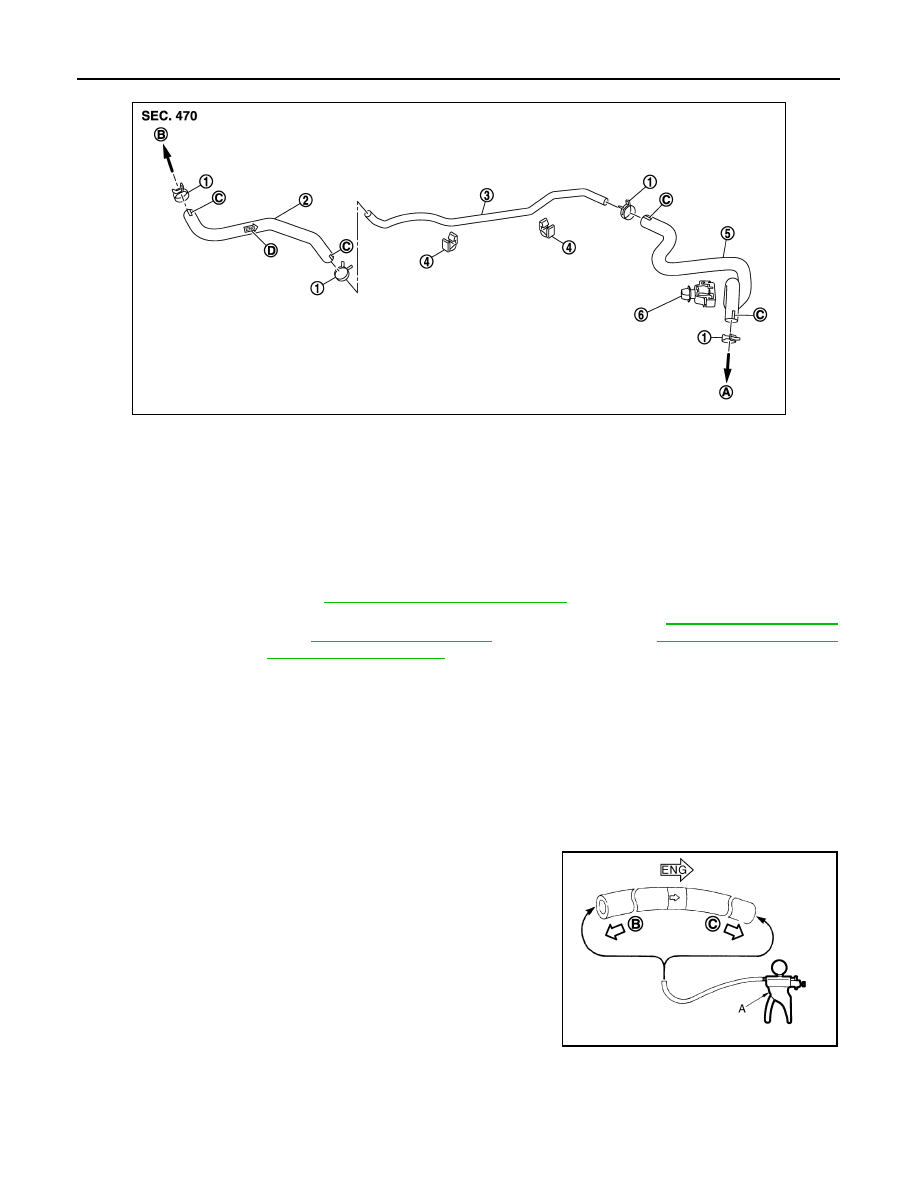

VACUUM LINES

R9M

Removal and Installation

INFOID:0000000010450973

REMOVAL

1.

Remove the cowl top. Refer to

EXT-29, "Removal and Installation"

.

2.

Remove the air duct assembly to the electric throttle control actuator. Refer to

(K9K engine models),

(R9M engine models),

(MR20 engine models).

3.

Disconnect the vacuum hose from the engine intake manifold.

4.

Disconnect the vacuum hose from the brake booster.

5.

Disconnect the vacuum hose from the clip.

6.

Remove the vacuum hoses.

INSPECTION AFTER REMOVAL

Appearance

Check for correct assembly, damage and deterioration.

Check Valve Airtightness

• Use a handy vacuum pump (A) to check.

• Replace vacuum hose assembly if vacuum hose and check valve

are malfunctioning.

INSTALLATION

IInstall the vacuum hose and tube.

CAUTION:

JPFIA0135ZZ

1.

Clamp

2.

Vacuum hose (built in check valve)

3.

Vacuum tube

4.

Clip

5.

Vacuum hose

6.

Grommet

A.

To vacuum pump

B.

To brake booster

C.

Paint mark

D.

Stamp indicating engine direction

When connected to the brake booster side (B) :

Vacuum should decrease within 1.3 kPa (10 mm-

Hg, 0.39 inHg, 0.013 bar) for 15 seconds under a

vacuum of -66.7 kPa (-500 mmHg, -19.70 inHg, -

0,667 bar).

When connected to the engine side (C) :

Vacuum should not exist.

JPFIA0024ZZ