Nissan Qashqai J11. Manual - part 886

FRONT DISC BRAKE

BR-15

< PERIODIC MAINTENANCE >

[LHD]

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

FRONT DISC BRAKE

BRAKE PAD

BRAKE PAD : Inspection

INFOID:0000000010305349

PAD WEAR

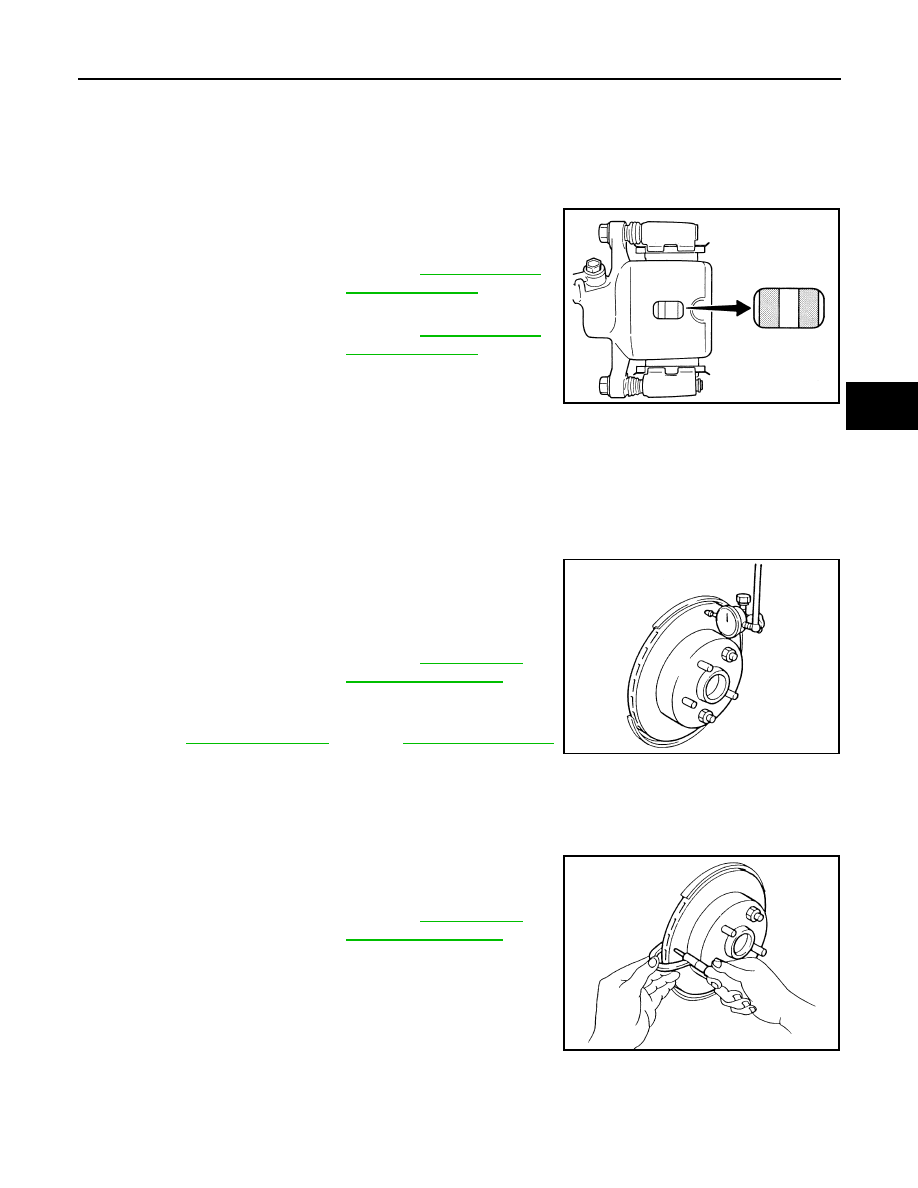

Check pad thickness from an inspection hole on cylinder body.

Check using a scale if necessary.

DISC ROTOR

DISC ROTOR : Inspection

INFOID:0000000010305350

APPEARANCE

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace if there are.

RUNOUT

1.

Fix the disc rotor to the wheel hub and bearing assembly with

wheel nuts (2 points at least).

2.

Inspect the runout with a dial gauge. [Measured at 10 mm (0.39

in) inside the disc edge.]

NOTE:

Check the wheel bearing axial end play before the inspection.

Refer to

(4WD).

3.

Find the installation position with a minimum runout by shifting the disc rotor-to-wheel hub and bearing

assembly installation position by one hole at a time if the runout exceeds the limit value.

4.

Replace or lathe the disc rotor if the runout exceeds the limit even after the above operation.

THICKNESS

Check the thickness of the disc rotor using a micrometer. Replace

the disc rotor if the thickness is below the wear limit.

Standard thickness

: Refer to

.

Wear limit thickness

: Refer to

.

BRA0010D

Runout limit

: Refer to

SBR019B

Wear limit thickness

: Refer to

SBR020B