Nissan Qashqai J11. Manual - part 845

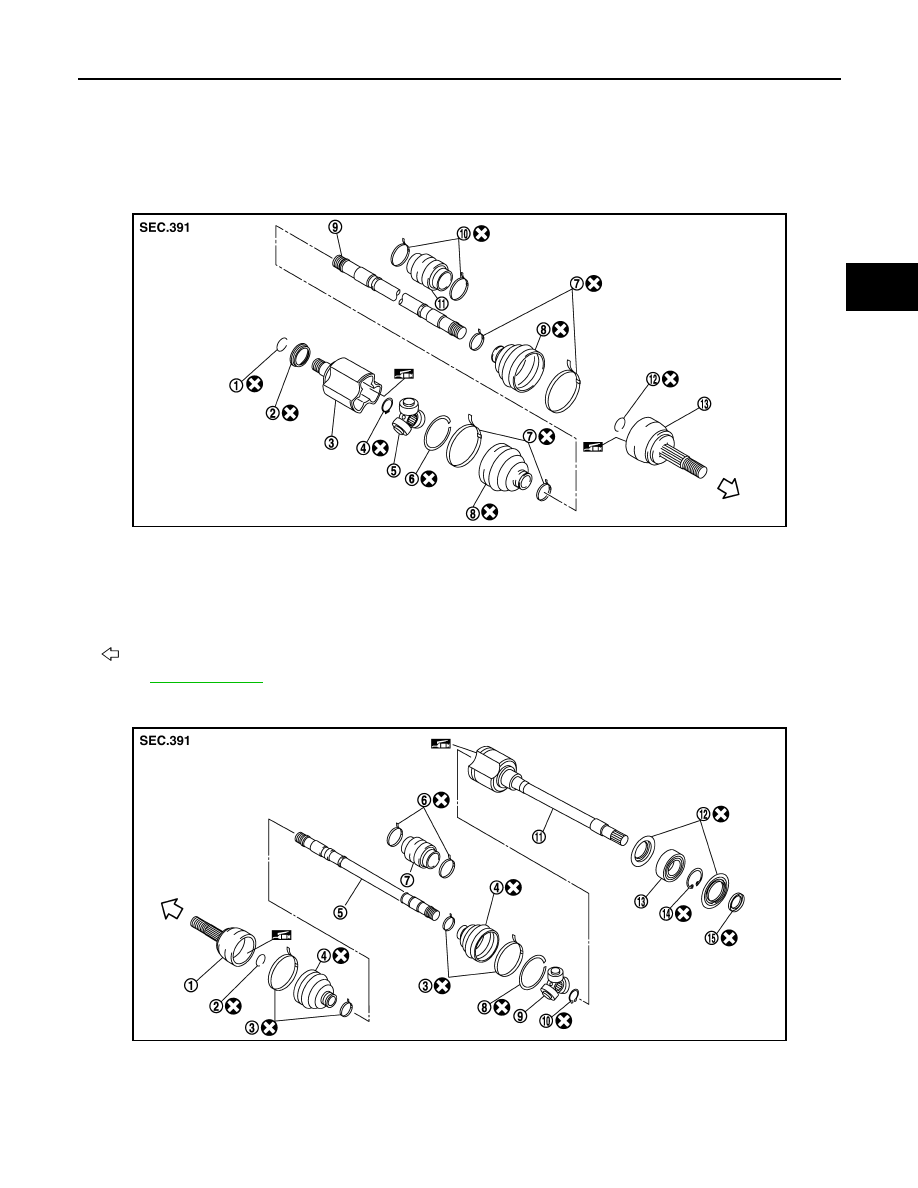

FRONT DRIVE SHAFT

FAX-67

< UNIT DISASSEMBLY AND ASSEMBLY >

[4WD]

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

UNIT DISASSEMBLY AND ASSEMBLY

FRONT DRIVE SHAFT

Exploded View

INFOID:0000000011722646

LHD models

RHD models - MR20DD

JPDIF0047ZZ

1.

Circular clip

2.

Dust shield

3.

Housing

4.

Snap ring

5.

Spider assembly

6.

Stopper ring

7.

Boot band

8.

Boot

9.

Shaft

10. Damper band

11.

Dynamic damper

12. Circular clip

13. Joint sub-assembly

Wheel side

Refer to

JPDIF0045ZZ

1.

Joint sub-assembly

2.

Circular clip

3.

Boot band

4.

Boot

5.

Shaft

6.

Damper band

7.

Dynamic damper

8.

Stopper ring

9.

Spider assembly

10. Snap ring

11.

Housing assembly

12. Dust shield