Nissan Qashqai J11. Manual - part 794

DLN-92

< UNIT DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY21C]

DRIVE PINION

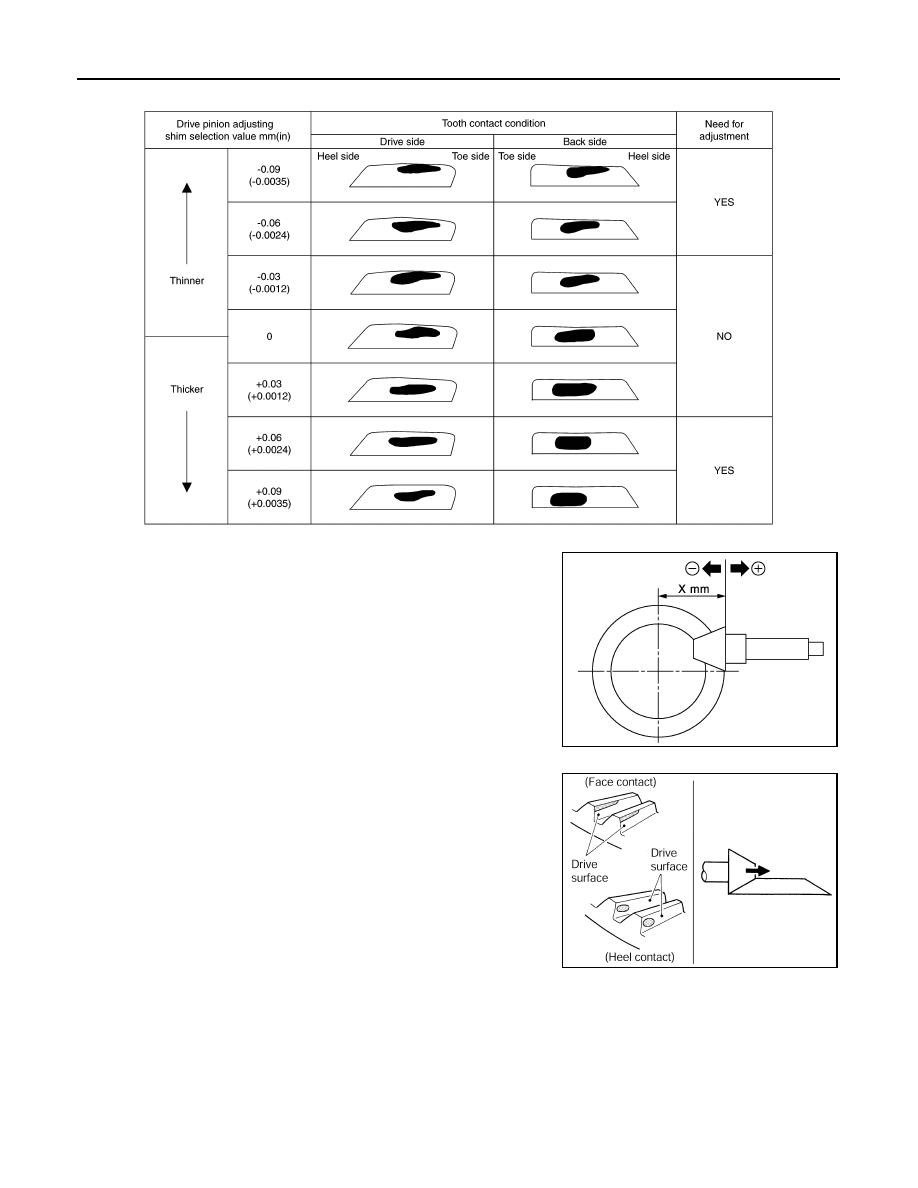

Tooth Contact Judgment Guide

8.

Follow the procedure below to adjust pinion height (dimension

X) if tooth contact is improper. For selecting adjusting shim, refer

to the latest parts information.

CAUTION:

If no adjusting shim with the calculated value is available,

select the thicker and closest one.

• Thicken the drive pinion adjusting shim to move the drive pin-

ion closer to the ring gear in case of face contact or heel con-

tact.

CAUTION:

Only one adjusting shim can be selected.

JSDIA4035GB

JSDIA1221ZZ

PDIA0440E