Nissan Qashqai J11. Manual - part 715

COMPONENT PARTS

TM-435

< SYSTEM DESCRIPTION >

[CVT: RE0F10G]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

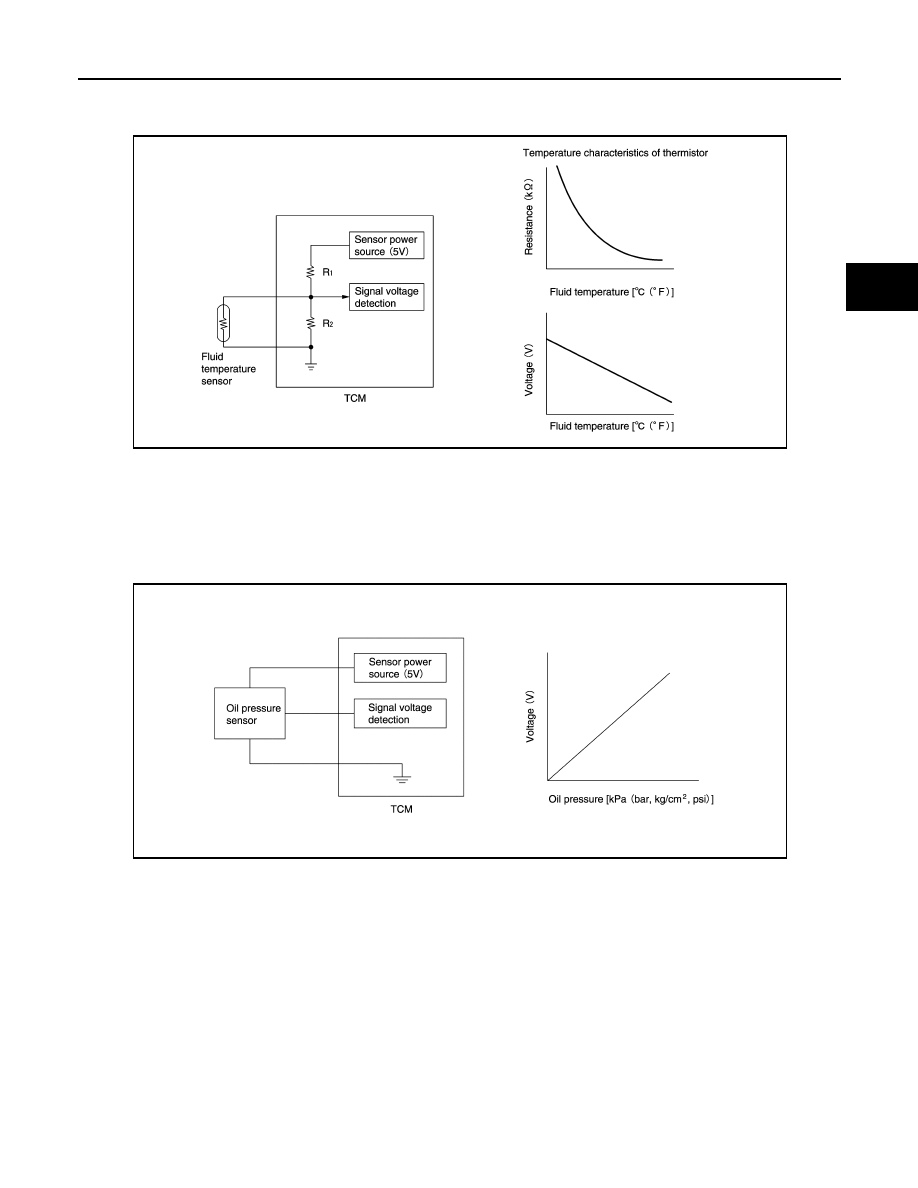

• The fluid temperature sensor uses a thermistor, and changes the signal voltage by converting changes in the

CVT fluid temperature to a resistance value. TCM evaluates the CVT fluid temperature from the signal volt-

age value.

CVT CONTROL SYSTEM : Primary Pressure Sensor

INFOID:0000000010245525

• The primary pressure sensor is installed to control valve.

• The primary pressure sensor detects the pressure applied to the primary pulley.

• When pressure is applied to the ceramic device in the primary pressure sensor, the ceramic device is

deformed, resulting in voltage change. TCM evaluates the primary pressure from its voltage change. Voltage

is increased along with pressure increase.

CVT CONTROL SYSTEM : Secondary Pressure Sensor

INFOID:0000000010245526

• The secondary pressure sensor is installed to control valve.

• The secondary pressure sensor detects the pressure applied to the secondary pulley.

JSDIA1825GB

JSDIA1831GB