Nissan Qashqai J11. Manual - part 709

FLUID COOLER SYSTEM

TM-411

< REMOVAL AND INSTALLATION >

[CVT: RE0F10D]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

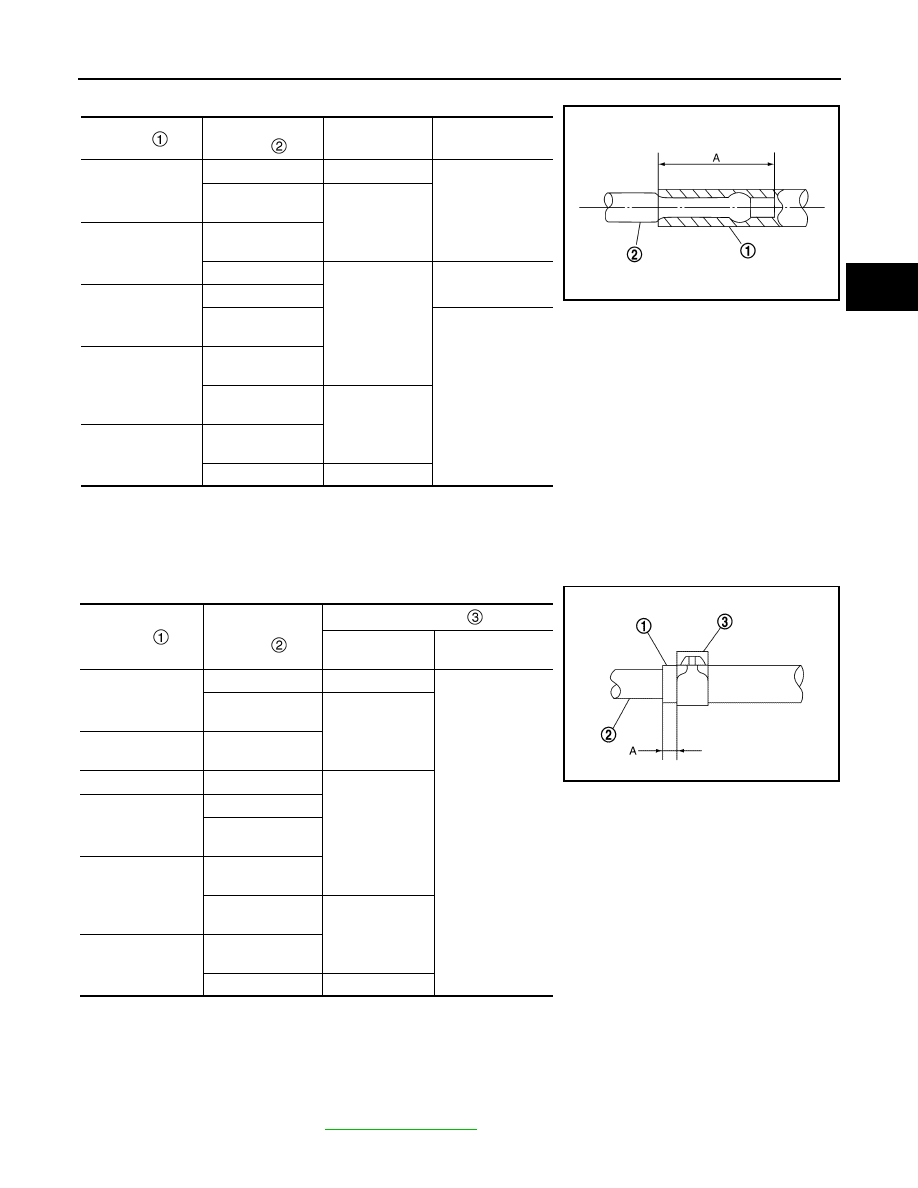

• Refer to the followings when installing fluid cooler hose.

•

• Refer to the followings when installing hose clamp.

CAUTION:

Hose clamp should not interfere with the bulge of fluid cooler tube.

Inspection

INFOID:0000000010589399

INSPECTION AFTER INSTALLATION

Start the engine and check visually that there is no leakage of CVT fluid.

ADJUSTMENT AFTER INSTALLATION

Adjust the CVT fluid level. Refer to

.

Hose

Installation side

tube

Direction of paint

mark

Hose insertion

depth (A)

Fluid cooler hose B

Fluid cooler tube A

Frontward

Hose end reaches

the 2-stage bulge.

Fluid cooler tube

assembly A

Leftward

Fluid cooler hose C

Fluid cooler tube

assembly A

CVT fluid cooler

Frontward

Hose end reaches

the end of tube

Fluid cooler hose D

CVT fluid cooler

Fluid cooler tube

assembly B

Hose end reaches

the 2-stage bulge.

Fluid cooler hose E

Fluid cooler tube

assembly B

Fluid cooler tube

assembly A

Leftward

Fluid cooler hose F

Fluid cooler tube

assembly A

CVT oil warmer

Upward

SCIA7203E

Hose

Installation side

tube

Hose clamp

Direction of tab

Clamping position

(A)

Fluid cooler hose B

Fluid cooler tube A

Upward

5 – 9 mm (0.20 –

0.35 in) from hose

end

Fluid cooler tube

assembly A

Leftward

Fluid cooler hose C

Fluid cooler tube

assembly A

CVT fluid cooler

Upward

Fluid cooler hose D

CVT fluid cooler

Fluid cooler tube

assembly B

Fluid cooler hose E

Fluid cooler tube

assembly B

Fluid cooler tube

assembly A

Leftward

Fluid cooler hose F

Fluid cooler tube

assembly A

CVT oil warmer

Upward

JSDIA2424ZZ