Nissan Qashqai J11. Manual - part 664

STRUCTURE AND OPERATION

TM-231

< SYSTEM DESCRIPTION >

[CVT: RE0F10D]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

The lubrication oil is the same as the CVT fluid which lubricates the entire transaxle.

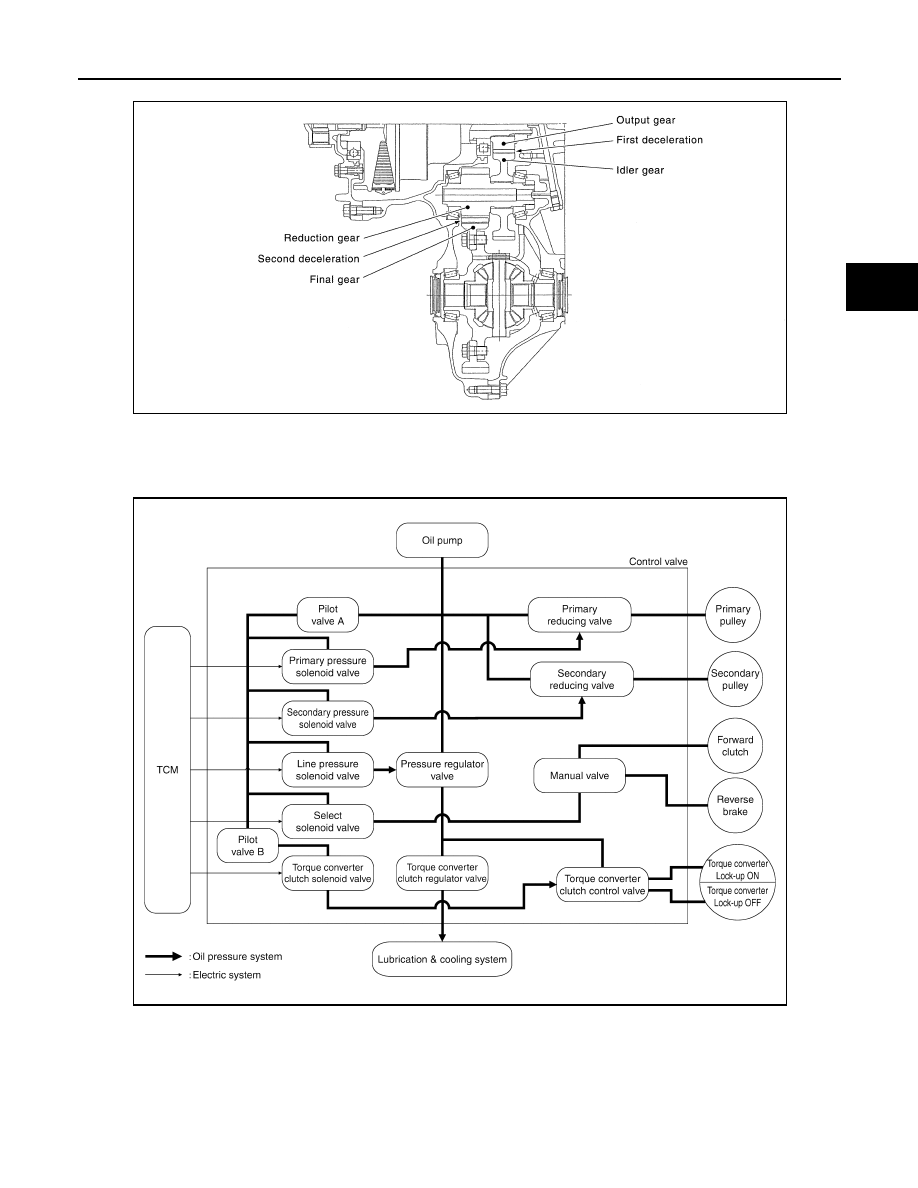

TRANSAXLE : Oil Pressure System

INFOID:0000000010589231

Oil pressure required for operation of the transaxle transmission mechanism is generated by oil pump, oil

pressure control valve, solenoid valve, etc.

JSDIA2427GB

JSDIA3786GB