Nissan Qashqai J11. Manual - part 635

INPUT SHAFT AND GEAR

TM-115

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F95R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

3.

Determine the thickness of the shim using the following procedure, accounting for the axial clearance

between 0 and 0.06 mm (0.0024 In).

a.

Permanent shim = (X2 - X1) - axial clearance.

b.

Example:

• X1 = 226.59 mm (8.9208 In).

• X2 = 227.56 mm (8.959 In).

• Permanent shim = (227.56 - 226.59) = 0.97 mm (0.038 In).

Given that shims vary by 0.040 mm (0.0002 In), in this example, it is necessary to use the 0.096 mm

(0.078 In) shim in the set.

Inspection

INFOID:0000000010428790

INPUT SHAFT AND GEAR

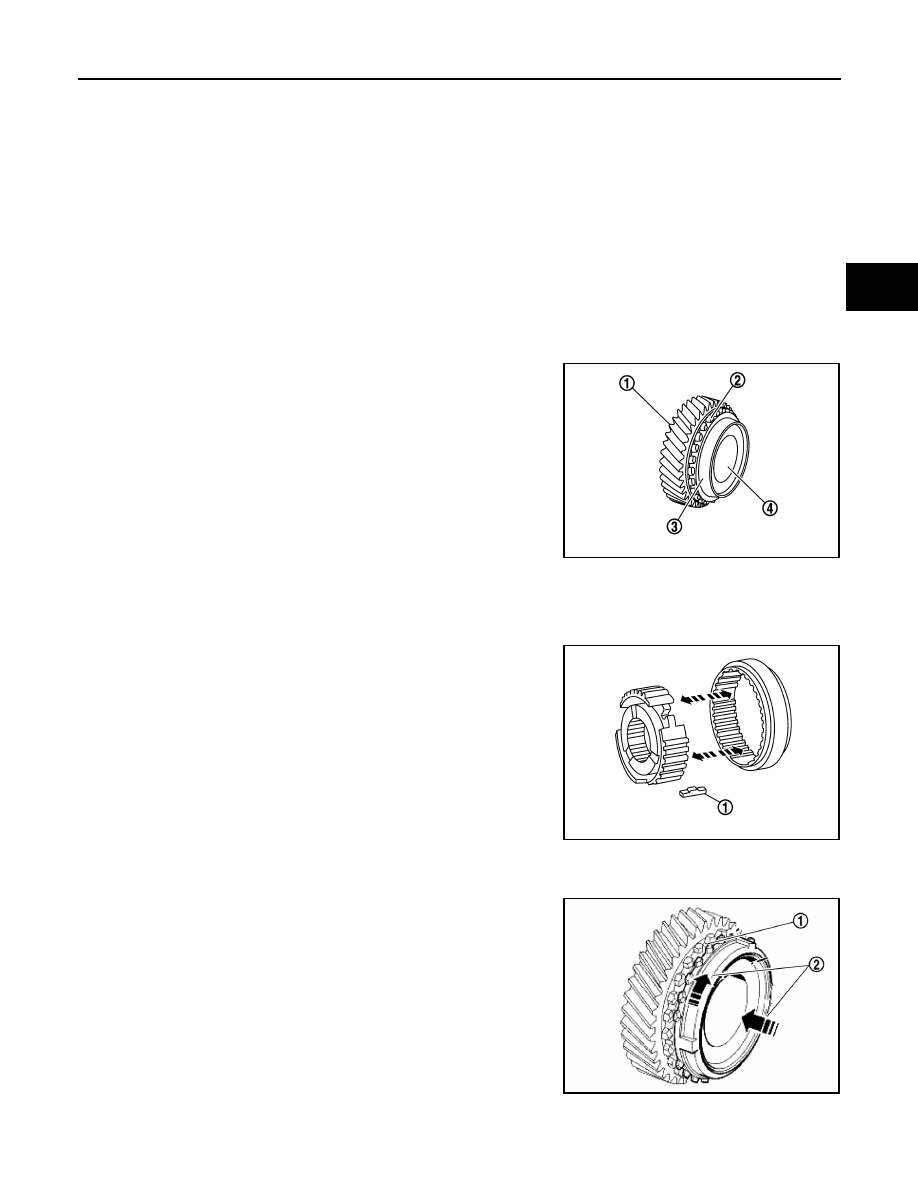

When checking, make sure that you pay particular attention to the

appearance of the teeth, especially that of the chamfers and claws.

Check that:

• the teeth (1) are not broken or chipped,

• the dogs (2) are not broken, chipped or worn,.

• the friction cone (3) shows no sign of scratches or blue stains,

• the inner wall (4) shows no sign of sticking or wear.

SYNCHRONIZER HUB

Check:

• that the selector rod slides onto the hub easily,

• that the collets (1) are in good condition.

SYNCHROMESH RING

Check that the dog teeth (1) show no sign of wear or any fractures.

To check that the synchroniser ring is working correctly, push the ring

on the friction cone and rotate (2) : the ring should not turn. Other-

wise, replace the synchroniser ring.

BEARING

E1DIA0250ZZ

E1DIA0251ZZ

E1DIA0252ZZ