Nissan Qashqai J11. Manual - part 615

TRANSAXLE ASSEMBLY

TM-35

< UNIT REMOVAL AND INSTALLATION >

[6MT: RS6F94R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

UNIT REMOVAL AND INSTALLATION

TRANSAXLE ASSEMBLY

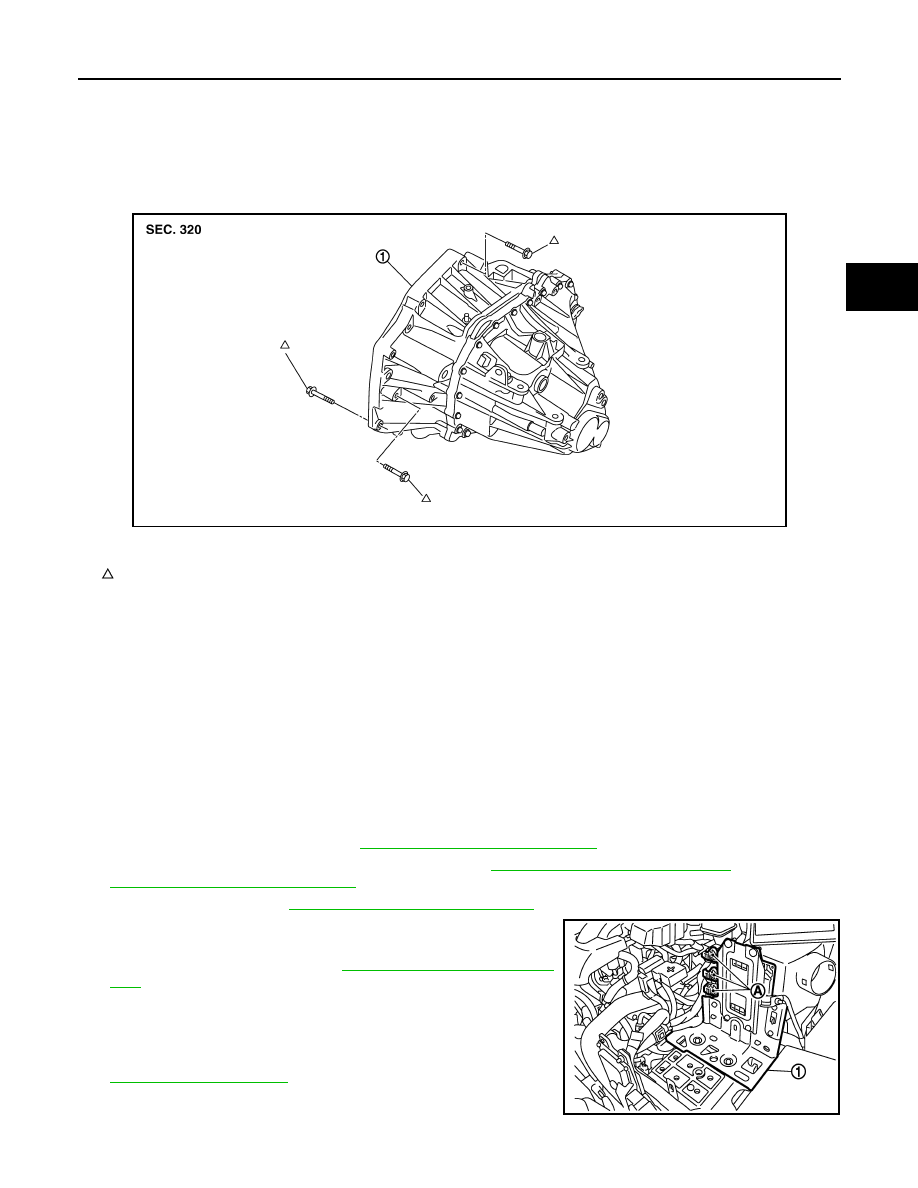

Exploded View

INFOID:0000000010288455

K9K, HRA2DDT and MR20DDT

CAUTION:

If transaxle assembly is removed from the vehicle, always replace CSC (Concentric Slave Cylinder). Return CSC insert to orig-

inal position to remove transaxle assembly. Dust on clutch disc sliding parts may damage seal of CSC and may cause clutch

fluid leakage.

Removal and Installation

INFOID:0000000010288456

CAUTION:

If transaxle assembly is removed from the vehicle, always replace CSC (Concentric Slave Cylinder).

Return CSC insert to original position to remove transaxle assembly. Dust on clutch disc sliding parts

may damage seal of CSC and may cause clutch fluid leakage.

REMOVAL

1.

Disconnect the battery cable from the negative terminal.

2.

Remove air breather hose. Refer to

TM-34, "Removal and Installation"

.

3.

Remove air cleaner case and air duct (inlet). Refer to

EM-23, "Removal and Installation"

(HRA2DDT) or

EM-279, "Removal and Installation"

(K9K).

4.

Remove battery. Refer to

PG-155, "Removal and Installation"

.

5.

Disconnect connectors (A) and then remove bracket (1).

6.

Drain clutch fluid and then remove clutch tube from CSC (Con-

centric Slave Cylinder). Refer to

CAUTION:

Never depress clutch pedal during removal procedure.

7.

Disconnect position switch harness connector.

8.

Remove crankshaft position sensor (POS). (For K9K) Refer to

.

CAUTION:

• Handle carefully to avoid dropping and shocks.

• Never disassemble.

JPDIC0148ZZ

1.

Transaxle assembly

: For the bolt mounting positions, refer to “INSTALLATION”.

JPDIA0240ZZ