Nissan Qashqai J11. Manual - part 573

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-37

< REMOVAL AND INSTALLATION >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

FL

N

P

O

8.

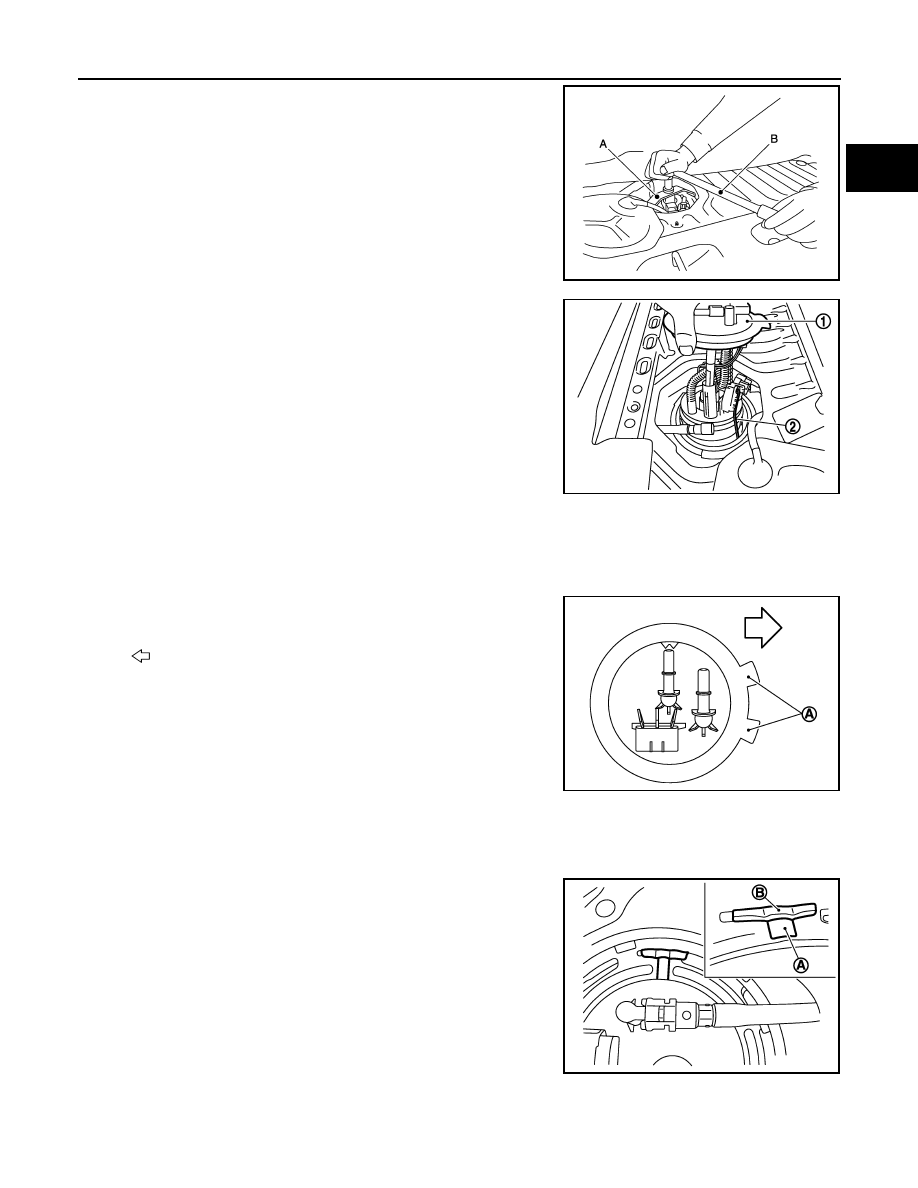

Use lock ring wrench [SST: KV101207S0] (A) to remove lock

ring.

CAUTION:

• To prevent lock ring wrench from being detached,

securely hold down spinner handle (B) by hand.

• To reduce impact caused by removal operation, use long

spinner handle [handle length: 60 cm (23.62 in) or more]

and slowly turn it counterclockwise.

9.

Remove fuel level sensor unit, fuel filter and fuel pump assembly

(1).

CAUTION:

• Never bend float arm (2) during removal.

• Never pollute the residual fuel inside of the tank. Draw out

avoiding inclination by supporting with a cloth.

• Never cause impacts such by dropping when handling

components.

INSTALLATION

Note to the following, and install in the reverse order of removal.

Fuel Level Sensor Unit

1.

Install new O-ring to fuel tank without any twist.

2.

Install the fuel gauge on the fuel tank with the fuel gauge top sur-

face (A) faced the front of the vehicle.

CAUTION:

• Never allow O-ring to drop.

• Never bend float arm during installing.

3.

Install lock ring for fuel level sensor unit, fuel filter and fuel pump assembly with lock ring wrench [SST:

KV101207S0] by turning clockwise.

CAUTION:

• Install lock ring horizontally.

• Turn the lock ring (A) until it is engaged in the fuel tank

side (B) as shown in the figure.

Quick Connector

• Connect quick connector as follows:

1.

Check the connection for damage or any foreign materials.

JSBIA1633ZZ

JPBIA3557ZZ

: Vehicle front

E1BIA1188ZZ

JPBIA3559ZZ